All of the diesel generator parts are combined in an electric machine to convert energy from one source into another energy form. Therefore, a power generator operates by taking mechanical energy to convert it into electrical energy.

In a nutshell, the Diesel Generator provides the alternator with mechanical energy, which is subsequently transformed into an electrical current in the presence of a magnetic field and electromagnetic induction. Understanding the Diesel Generator Parts is critical to getting the most out of this product. Diesel Generator Parts are available from a variety of Suppliers And Companies, as well as various manufacturers and distributors, and there are several Diesel Generators For Sale on Linquip.

There is a complete list of diesel generator services on the Linquip website that covers all factory operations. Linquip providers can assist you with this. Please contact Linquip’s Diesel Generator Parts Experts to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality items.

Unlike what many may think, there is not any actual electricity creation. Therefore, the operation of a single electric generator or multiple synchronous generators is based on Michael Faraday’s theory of electromagnetic induction. We will explain this when we talk about different diesel generator parts.

Electric Generator

An electric generator is a machine used to produce electrical power, which can be used for many applications, from small power appliances to large industrial machines. A popular option is to use grid power generated from fossil fuels or wind turbines and a steam turbine in a power plant.

There are many generator types, including petrol generators, portable generators, inverter generators, home generators that may work on natural gas, standby generators to hold power on during an outage, and very larger industrial generators. This article will mainly explain diesel generators known as gensets, their working principles, and their fundamental parts.

Diesel Generators

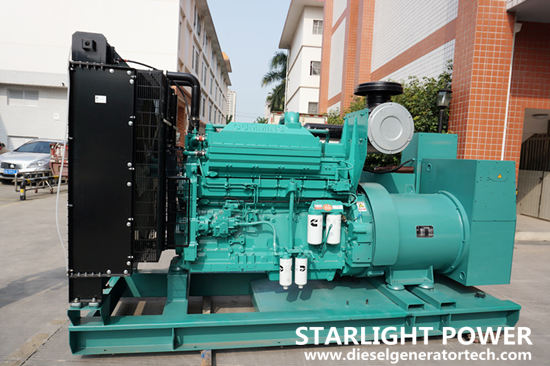

Diesel generators produce either continuous or standby power to different users like homes, schools, hospitals, and industrial centers. They can be small enough to be easily carried or large enough to fit in houses. However, there is a suitable unit for each user. Diesel generators convert fuel energy into electrical energy to provide power to the loads.

Diesel Generator Parts

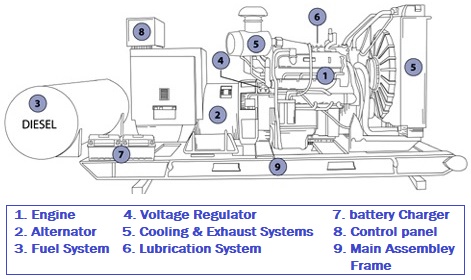

Each diesel generator is made up of at least nine components. Here, we will explain the different diesel generator parts. In the following figure, the main diesel generator parts are numbered and named.

10 Parts of the Diesel Generator are:

- Diesel Engine

- Alternator

- Fuel System

- Voltage Regulator

- Cooling System and Exhaust System

- Lubrication System

- Battery Charger

- Control Panel

- Main Assembly Frame

- What Is B Check In DG?

Diesel Engine

A diesel engine is the source of mechanical energy. The size of the engine is important because it is directly proportional to the amount of electrical energy produced. This means that if the desired output power is higher, the engine size will be larger. The diesel engine type is also a common type used in cars, trucks, or large vehicles. Here you can learn more about diesel engines and their working principles.

Alternator

The alternator is the component responsible for power output generation. Here, electromagnetic induction comes into play described in the following.

An alternator contains many complex parts, but one of the most significant components is the rotor. It consists of a shaft that rotates by the mechanical energy provided by the engine and multiple permanent magnets installed around it, and consequently, a magnetic field is created.

This magnetic field continuously spins around another important component of the alternator, which is the stator. This is a set of different electrical conductors firmly wound over an iron core. The principle of electromagnetic induction says that if an electrical conductor stays stationary and a magnetic field goes around it, an electrical current is induced.

To sum up, the alternator uses mechanical energy generated by the diesel engine to drive the rotor and create a magnetic field moving around the stator, which causes an alternating current.

Fuel System

The fuel system generally consists of a fuel tank with a pipe connecting it to the engine. Here, diesel can be provided directly for the engine to start the process explained earlier. The fuel tank size eventually manages the time a generator can be active.

A wide range of silent canopy generators is usually provided as standard with the fuel tanks on the base of the electric generator. Suppose a larger capacity of fuel is required; In this case, we can design and produce a bespoke extended base fuel system or the attached unit to an extra free-standing bulk fuel tank (a silent diesel generator has a steel or plastic surround to decrease the noise.)

For larger power generator plans that need the genset to be placed into an acoustic room, separate fuel systems are normally located either inside or beneath the room or sometimes both.

Voltage Regulator

The voltage regulator is the most complicated component of an electric generator. This part has an explanatory purpose, which is regulating the voltage output. What goes on in the voltage regulator is very detailed, which is not described in the current article.

It guarantees that the generator generates electricity at a proper steady voltage. In the absence of a voltage regulator, extreme fluctuations occur depending on the engine speed. All the electrical devices we use cannot control such an unsteady power supply. Thus, the goal of using this part is to keep everything smooth and uniform.

Cooling System and Exhaust System

These two parts both have essential functions. The responsibility of the cooling system is to prevent the generator from overheating. The coolant is released in the generator, which counteracts all the engine and alternator extra heat energy. The coolant then takes all of this heat through a heat exchanger and discharges it outside the generator.

The exhaust system operates similarly to the car exhaust. It captures any gases produced by the diesel engine, enters them through the piping system, and removes them from the Genset.

Lubrication System

The lubrication system is a part that connects to the engine and pumps oil into it to ensure every part works smoothly and does not grind against other parts. Without a suitable lubrication system, the machine will break down.

Battery Charger

A diesel engine requires a tiny electrical motor to help put it into action. The small motor works with a battery, which needs to be charged.

Control Panel

This part is just in the case of controlling and operating the generator. This has every controlling object, including the start button, a frequency switch, an engine fuel indicator, a temperature indicator of the coolant, and much more, enabling the user to do different works or check certain things.

The control panel starts and terminates the generator, and monitors the engine and alternator to implement monitoring, maintenance, and control. The control panel ensures everything runs properly. It can also provide synchronizing for parallel work activation.

Main Assembly Frame

Every generator needs to be held in some way, and this is the main frame of the assembly. It houses the whole generator and is where all the different diesel generator parts are made onto.

It holds everything together, and it might be an open design – or closed (canopied) for extra safekeeping and sound attenuation. The outdoor generators are usually housed in a protective frame that is weatherproof for damage prevention.

What Is B Check In DG?

B-check is done once a week or after (300-350) hours of running. The following parameters should be examined in this sort of check: * Replace the oil. * Replace the oil, fuel, and bypass filters. * Replace the air filter. * Replace the water separator if necessary. In diesel engines, the most typical coolant is water.

Conclusion

You became familiar with how a diesel generator works and all the diesel generator parts. In short, the diesel engine supplies the mechanical energy of the alternator, which is then converted to an electrical current in the presence of a magnetic field and electromagnetic induction.

Download Diesel Generator Parts PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- Industrial Diesel Engine Services

- Industrial Diesel Engine Installation Services

- Industrial Diesel Engine Maintenance Services

- Industrial Diesel Engine Services in Texas

- Industrial Diesel Engine Installation Services in Texas

- Industrial Diesel Engine Maintenance Services in Texas

- Caterpillar Industrial Diesel Engines Products

- Caterpillar Heavy Duty Diesel Engine Products

- Caterpillar Marine Diesel Engines Products

- Caterpillar Heavy Duty Gas Engine Products

- Caterpillar Diesel Generator Set Products

- Caterpillar Heavy Duty Diesel Generator Set Products

- What are The Electric Generator Parts?

- Parts of DC Generator: Explanation of Parts, Working, Types, Advantages & Disadvantages

- Working Principle of Diesel Generator

- The Difference Between Diesel Engine and Petrol Engine: which one best works for you?

- Parts of DC Generator: Explanation of Parts, Working, Types, Advantages & Disadvantages

- Parts of Generator: a Simple, Yet Useful Guide

- Diesel Engine Working: everything you need to know

- The Best Diesel Generator of 2021

- Types of Generators: Learn the Basics, Get the Most Out f it!

- A Clear Classification of AC Generators

- What are The Electric Generator Parts?

- What are the parts of AC Generators?

- Parts of Generator: 10 Main Components of Generators

- Electric Generator Maintenance, Repair, and Services (2022 Guide)

- Gasoline Generator Repair and Maintenance (2022 Guide)

- How Much Does It Cost to Install a 22kW Generac Generator?

- How Long Can A Standby Generator Run Continuously?

- What is the Difference Between a Whole House and Standby Generator?

- The Difference Between Prime & Standby Generators

- Can I install a Standby Generator Myself? (An All-In-One Guide)

- Portable vs. Standby Generator (Best Choose for Home in 2022)

- DC Generator Repair, Maintenance & Testing 2022 (Full Guide)

- Pros and Cons of Inverter Generators in 2022

Send me more electrical components and power factor system technical information, sir.

Thanks for visiting our website, Lalit! You can visit our Industrial Equipment page, where you can find various electrical components based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.

helpful, thak you

Thanks for visiting our website, Mugisha! We also encourage you to visit the Linquip website, where you can find numerous industrial equipment, along with companies and experts.

Great blog. Thanks for sharing such valuable content. Find Best List of Electric Generator Manufacturers & Suppliers.

Your kind words are much appreciated! It was a pleasure having you visit us.

Really appreciate your content .Thanks for sharing informative blog.

Thank you so much for visiting our website, Raoamar! We are eager to hear more from you in the future.