We want to talk about the Pelton wheel turbine as an impulse turbine. As you know, there are various types of water turbines according to inlet available energy. The main categories are reaction turbines and impulse turbines.

In an impulse turbine, the potential energy of the water or the water head is converted into kinetic energy at first by discharging water through a carefully shaped nozzle. The jet, which is released into the air, is directed to curved buckets fixed on the runner’s periphery to extract the energy of water and convert it into beneficial work. The Pelton wheel is the most famous sample of an impulse turbine. A description of all you may need to know around Pelton wheel turbines is elaborated in what follows.

On the Linquip platform, you can find all the information you need about Pelton hydro turbine equipment and devices. Our experts are available to answer any questions you may have about the Pelton wheel. To get started, read Linquip’s article titled, “What is Pelton Hydro Turbine?“. To gain access to all of Linquip’s features, you need to register as a Linquip Expert.

Have you considered contributing to the Linquip platform by Guest Posting? There is an option for guests to submit posts on Linquip.

What is a Pelton Wheel?

The Pelton wheel turbine is one kind of an impulse turbine utilized for high heads of water (greater than 300 meters) and was invented by an American Engineer, Lester Allan Pelton.

The energy available at the turbine inlet is only kinetic. The pressure is atmospheric at the inlet and outlet of the turbine.

Pelton wheel turbine is a hydraulic turbine, and its primary application is in the hydropower plant for producing electricity.

In 2012, hydroelectric power plants were responsible for producing about 16% of the total electricity around the world.

Hydroelectricity is the most broadly practiced form of renewable energy. It is a resilient source of electricity that is generated at a relatively low price.

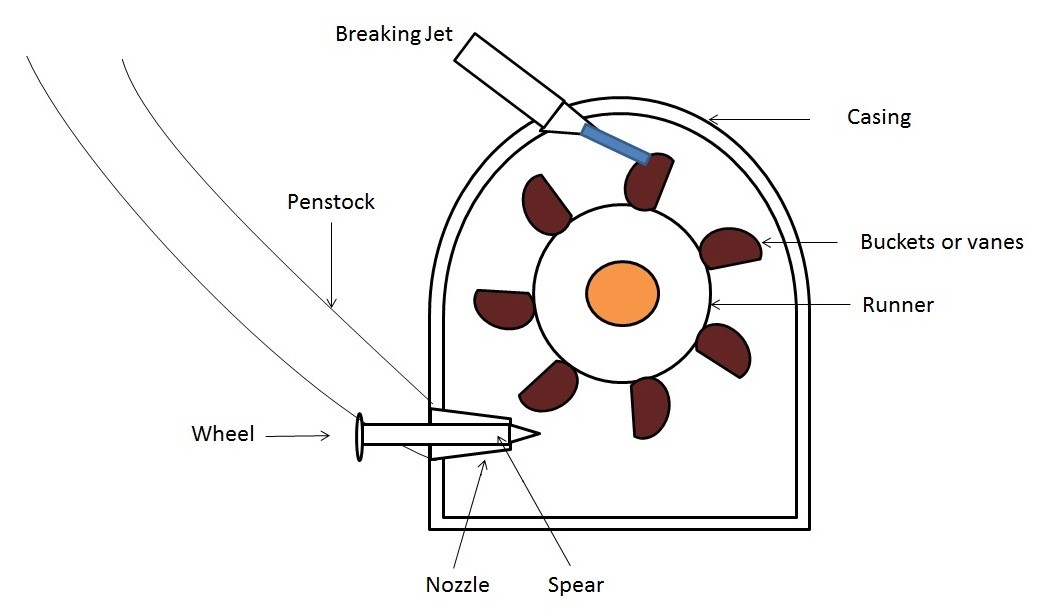

Parts of a Pelton Wheel Turbine:

Each Pelton wheel turbine is comprised of many parts, which four of those major parts are as below:

- Nozzle

- Runner and buckets

- Casing and

- Breaking jet

Nozzle:

The nozzle is used to enhance the kinetic energy of the water that will strike the buckets or vanes connected to the runner.

The amount of water hitting the runner’s buckets is controlled by implementing a spear in the nozzle.

The speed is a conical needle that is performed either automatically or by a hand wheel in an axial direction regarding the unit’s size.

When the spear is pushed forward to the nozzle, the volume of water striking the runner is diminished. Conversely, if the sphere is pushed back, the amount of water hitting the runner grows.

Runner and Buckets

In a Pelton wheel turbine, the runner or blade is a circular disc on the periphery of which several buckets evenly aligned are fixed. The bucket is a double hemispherical cup or bowl which is divided into two symmetrical parts by a dividing wall known as a splitter.

The jet of water hits on the splitter and is divided into two equal parts. The jets go out at the outside edge of the bucket. The bucket is formed so that the jet gets deflected through 160 degrees or 170 degrees.

The bucket is made of cast steel bronze, cast iron, or stainless steel, depending upon the head at the turbine’s inlet.

Casing

The outer covering in the Pelton turbine is called the casing, which is made of cast iron or fabricated steel plates.

It inhibits the splashing of the water and helps to release the water to the trail race. It also acts as a protection in case an accident occurs.

Breaking Jet

When the water jet is entirely closed by pushing the spear in the forward direction, the volume of water striking the runner converts to zero. Yet still, the runner keeps running due to the inertia of the runner.

To hinder the runner in the shortest reasonable time, a tiny nozzle is provided directing the water jet at the back of the vanes. This jet of water, which is applied to stop the runner of the turbine, is known as the breaking jet.

Watch Video About Pelton Wheel

Working Principle

Here, we want to review the working of the Pelton wheel turbine.

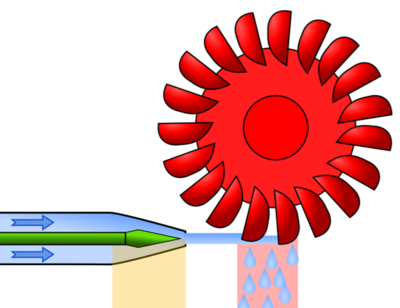

Water flows from the nozzle with high kinetic energy along the runner’s path. When the water jet comes in touch with the bucket, it exerts a push on the bucket, which is called the impulse force.

The nozzle applied at the end of the penstock is provided with a spear or needle, which is fixed at the end of a rod to control the water quantity hitting the runner.

During this process, the momentum of the water is conveyed to the turbine. The impulse force generated due to this momentum of water makes the turbine rotate.

The double semi ellipsoidal buckets split the water jet into two equal amounts, which helps in balancing the wheel(runner). This guarantees a smooth transfer of the water jet to the turbine wheel.

For maximum efficiency and power, the turbine is designed in a way that the velocity of the water jet is twice that of the bucket. For a better understanding of the Pelton wheel, click here.

Advantages of Pelton Wheel

Pelton Wheel Turbine has some advantages as below:

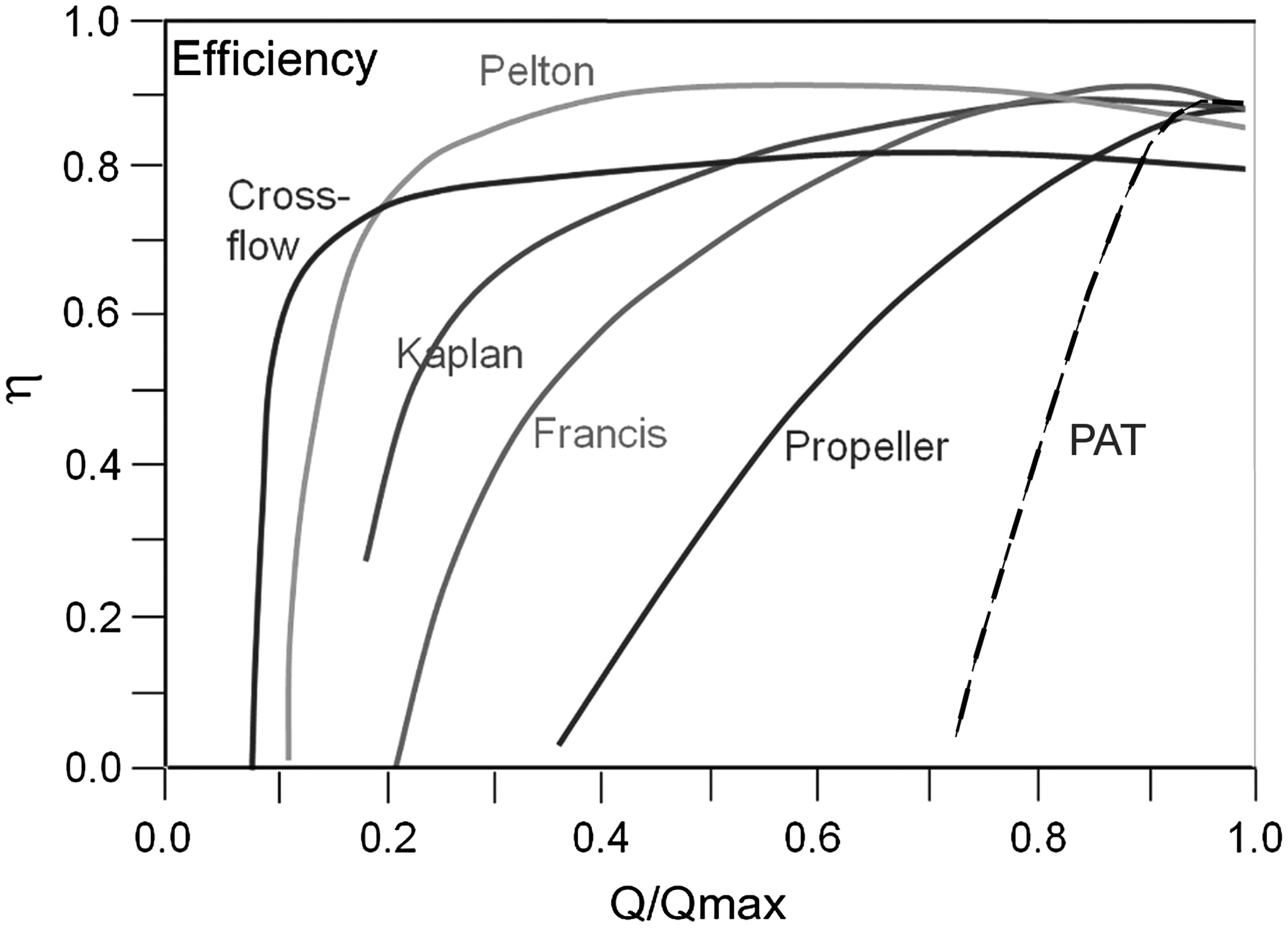

- The Pelton wheel turbine is the most efficient available hydro turbine.

- It operates at a very flat performance curve.

- It works on low discharge and high head.

- It has fewer parts in comparison with Francis’s turbine, which has both guided vanes and fixed vanes.

- It can have both axial flow or radial flow.

- Pelton wheel turbine can be assembled easily.

- The water jet strikes only a specific portion of the runner in the Pelton wheel, so the cavitation will not occur.

- `Pelton wheel turbine has high overall efficiency.

- The first law in addition to the second law of motion are applied in this kind of turbine.

- In this turbine, the main advantage is that the whole process of the water jet hitting and leaving the runner occurs at atmospheric pressure.

Disadvantages of Pelton Wheel

Some disadvantages of Pelton Wheel Turbine are presented here:

- The efficiency diminishes promptly with time.

- The runner, powerhouse, and generator are large in this turbine.

- There are some challenges in controlling the operating head because of the high heads.

Applications of the Pelton Wheel

The applications of the Pelton Wheel Turbine are as follows:

- The Pelton wheel is the preferred turbine for hydropower when the accessible water source has a comparatively high hydraulic head at low flow rates. The head is from 150 meters to 2000 meters in hydroelectric powerplants.

- In a hydroelectric power plant, this is employed to drive the turbine’s generator to generate the turbine mechanical energy into electrical energy.

- To obtain the highest power and efficiency, the turbine blades are designed in a way that water jet speed is twice the speed of rotating buckets.

- It is also applied as set up in the laboratories of Educational Institutions.

Efficiency and Mathematical Formulas for Pelton Wheel Turbine:

In what follows, the formulas for the calculation of important outputs of a Pelton wheel are presented.

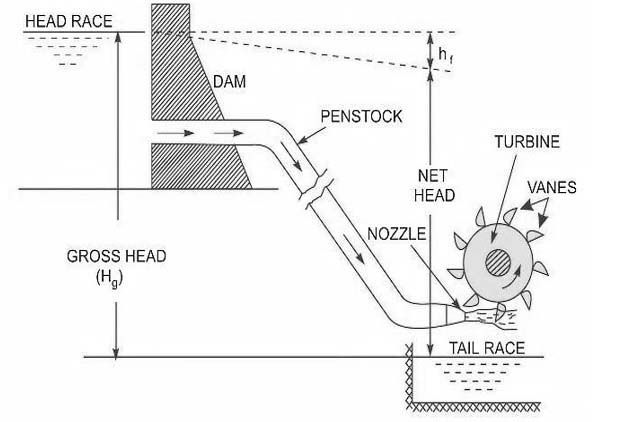

Hydraulic Efficiency:

It is the ratio of power produced by the runner of the turbine to the water-energy supplied to the bucket of the runner.

{ \eta }_{ h }=\frac { Power\quad Developed\quad by\quad the\quad Runner }{ Power\quad Supplied\quad at\quad the\quad Inlet\quad to\quad the\quad Turbine }The expression can also be written as:

{ \eta }_{ h }=\frac { Power\quad Developed\quad by\quad the\quad Runner }{ \rho QgH }where

H = Net head developed by the water at the inlet,

The head can find by

H={ H }_{ g }-{ h }_{ f }where

{ h }_{ f }=\frac { fL{ V }^{ 2 } }{ 2gD }.Mechanical Efficiency:

The mechanical efficiency is defined as the power available at the shaft to the power produced by the runner.

{ \eta }_{ m }=\frac { Power\quad Available\quad at\quad the\quad Turbine\quad Shaft }{ Power\quad Developed\quad by\quad the\quad Runner } { \eta }_{ m }=\frac { P }{ Power\quad Developed\quad by\quad the\quad Runner }Volumetric Efficiency:

The volumetric efficiency is a ratio of the actual quantity of water on the runner blades to the net quantity of water supplied to the turbine is known as volumetric efficiency.

{ \eta }_{ v }=\frac { Quantity\quad of\quad Water\quad Actually\quad Striking\quad the\quad Runner }{ Quantity\quad of\quad Water\quad Supplied\quad to\quad the\quad Turbine } { \eta }_{ v }=\frac { Q }{ Q+\Delta Q }Overall Efficiency:

The overall efficiency in a Pelton wheel turbine is defined as a ratio of the power available at the shaft to the net power available at the base of the nozzle. In other words:

{ \eta }_{ o }=\frac { Power\quad Available\quad at\quad the\quad Turbine\quad Shaft }{ Power\quad Supplied\quad at\quad the\quad Turbine\quad Inlet } { \eta }_{ o }=\frac { P }{ \rho QgH }

Mathematical Formula of Pelton Wheel:

The formula for calculating the specific speed of a Pelton wheel is

{ \eta }_{ s }=\frac { n\sqrt { P } }{ \sqrt { \rho } { (gH) }^{ 5/4 } }where

n= Frequency of rotation (rpm),

P= Power (W),

H= Water head (m)

\rho = Density (kg/m3)The flow ratio in a Pelton wheel is the ratio of the velocity of flow at the inlet to the energy head at the inlet of the turbine. In other words:

{ C }_{ v }=\frac { { V }_{ l } }{ \sqrt { 2gH } }

The speed ratio: It is the ratio of Peripheral velocity to the energy head at the inlet

{ K }_{ u }=\frac { U }{ \sqrt { 2gH } }

The Peripheral velocity: In the case of the Pelton Wheel, the velocity at the inlet (U1) is equal to the velocity of the outlet (U2)

U=\frac { \pi DN }{ 60 }

Calculation of Power:

The power can be calculated by

P=Fu=T\omegawhere

\omega =Angular velocity of the wheel.Download Pelton Wheel PDF

You can download a PDF file of this article if you need to refer back to it at any time.

Read More on Linquip

- Differences between Pelton, Francis, and Kaplan Turbine

- Types of Turbines: Classifications and Types

- Open Cycle Gas Turbine: A Detailed Overview

- 6 Best Home Wind Turbines (Residential): A Practical Guide

- Differences between Pelton, Francis, and Kaplan Turbine

- Gas Turbine Cycle: Everything You Need to Know About Gas Turbine Working Principle

- An Ultimate Guide to Francis Turbine

- What is Kaplan Turbine? Diagram and Working Principles

- Efficiency of Wind Turbines

- The 8 Best Home Wind Turbines in 2022

Thank you so much for your review and for bringing this to our attention. We couldn’t agree more with what you wrote. Please sign up on Linquip with any further comments or suggestions you wish to share. Again, thank you for taking the time to review our article!

wow really useful for intro thank you.

Thanks for visiting our website and leaving your comment, Kristen! We hope to hear from you again in our other posts.