What is a shunt DC motor ? How does it work or what is its working principle? What parts does it consist of? What applications is it used for? These are the questions that everyone should ask before purchasing a DC motor.

A DC shunt motor is a self-excited DC motor with field windings that are shunted to or linked in parallel with the motor’s armature winding. The Shunt DC Motor is an important Product to use in electrical applications. Shunt DC Motors are provided by several Suppliers and Companies, different manufacturers, and a lot of distributors and there are a lot of Shunt DC Motors for Sale on Linquip.

There is a complete range of Shunt DC Motors services on the Linquip website that covers all of your electric demands. Linquip vendors can assist you with this. Please contact Shunt DC Motors Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

Linquip, as always, has gathered a broad set of information about these questions so that you can make an easier choice and a more suitable purchase. In the following sections, we will elaborate on each of these issues and dig deeper into each of these areas. Let’s have a look at what a Shunt DC motor is and what it does. Read on to have your answers.

What Is a Shunt DC Motor?

A shunt motor (known as a shunt wound DC motor) is a type of DC motor which is self-excited and has the field windings that are connected in parallel to the armature winding of the motor. As these two parts are connected in parallel, the armature and field windings are exposed to the same supply voltage. The shunt winding is made up of many turns of small copper wire and since it is connected across the DC field supply, its field current will be constant. After all, there are separate branches for the flow of armature current and field current.

The difference in constructions of SDC motors and shunt motors leads to some variation in operation between these two main types of DC motors. Among all the differences between these two types of DC motors, the most significant one is their speed characteristics. Where a series motor shows a direct, inverse relationship between the load and the speed, while a shunt motor can maintain a constant speed, regardless of the load on the motor.

shunt motors are used wherever there is a request for stable speed. Shunt DC motors can be used in centrifugal pumps, lifts, weaving and lathe machines, blowers, fans, conveyors, spinning machines, and more.

How Does a Shunt DC Motor Work?

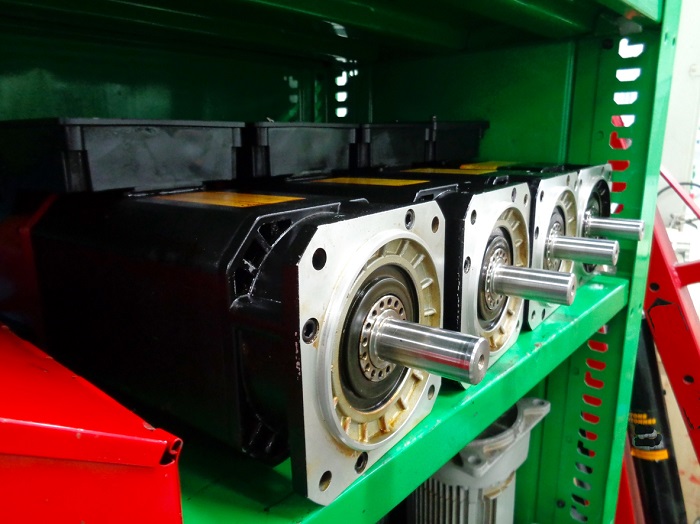

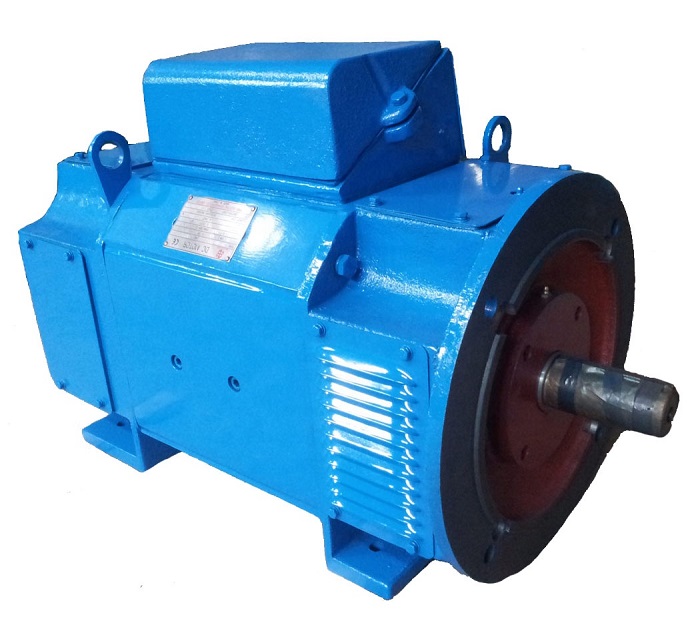

The construction and design of shunt motors are the same as other types of DC motors. The structure of this motor is made up of the basic parts of other DC motors such as field windings or the stator, a commutator, and an armature or the rotor.

But how does a shunt motor work? As long as a shunt motor is turned on, a direct current flows throughout the stator as well as the rotor. This flowing current will create two fields namely the pole and the armature. There is an air gap between armature and field windings which is filled with two magnetic fields. Their job is to respond with each other to turn and revolve the armature.

In addition to these two parts, there is a commutator in shunt DC motors. The commutator overthrows the direction of the current flow of the armature at ordinary gaps. So the armature field is forced back with pole field for all time and this phenomenon keeps the armature revolving within an equal direction.

What Is the Difference Between DC Motor and DC Shunt Motor?

A DC compound motor’s shunt field is wound for the most part, with a few turns of series winding on top. The armature and the series turns are arranged in series, and the shunt is placed across the field supply. This results in a motor that has both shunt and series properties.

Where Are DC Shunt Motors Used?

Shunt motors are utilized in applications where a constant speed is required. Centrifugal pumps, weaving and lathe machines, lifts, fans, blowers, spinning machines, conveyors, and other applications use shunt DC motors.

Shunt DC Motors Speed Control

You can easily control the Speed of a Shunt motor. Despite the load changes, Shunt motors can maintain their constant speed. As the load increases the armature slows down its speed. This results in less back electromagnetic force. This less back EMF accounts for less opposition against the supplied voltage. So, the motor will draw more current. This increase in current leads to an increase in torque to gain speed. so, if the load increases, the net effect of load on speed in a Shunt motor is almost zero. When the load decreases, the armature moves faster and creates more back EMF. because the polarity of the back EMF is against the supply voltage, load reduction causes less current and hence the speed remains constant.

Remember that the speed of a shunt DC motor can be controlled either by varying the amount of current supplied to the field windings or by varying the amount of current supplied to the armature.

As the armature draws more current, the current control rheostats used with armature are usually much larger than those used for shunt current control. Generally, motors come with a specified rated voltage and rated speed in rpm. When Shunt DC motors operate below its full voltage, its torque gets reduced.

Installation of a Shunt DC Motor

It can be very easy if you try to install a Shunt DC motor. Its installation contains two sections. The first one is the mechanical installation of the motor and its load, and the second one is the installation of electrical wiring and accompanying speed controls. While you install the motor you have to be sure that the motor shaft and load shaft are correctly and fittingly aligned. Any type of misalignment will result in stress on armature bearing, which is dangerous for the motor functioning.

The Applications of the Shunt Motors

Shunt motors are ideal for applications where precise speed control is required. Due to their self-regulating speed capabilities, they can be a good choice. Remember that shunt DC motors cannot produce high starting torque, so the load at startup must be small. Applications that correspond to these criteria and are suitable for shunt motors include machines and tools such as lathes and grinders and industrial equipment such as fans and compressors.

Conclusion

In this article, we tried to show you what exactly shunt DC motors do. To answer this question, we analyzed the working principle of a shunt motor and told you how it works. We explained the rules a shunt motor follows to do its job. After that, we delved into different and main parts of it and their cooperation. At last, we talked about the installation and the applications of shunt motors. If you have any experience of using different types of motors, we will be very glad to have your opinions in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Download Shunt DC motor PDF

Read More on Linquip

- All About DC Motor Types and Their Applications

- Differences Between Motor and Generator

- Series Wound DC Motor

- Series DC Motors: A Comprehensive Guide

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Compound DC Motors: Everything You Should Know About DC Compound Motors

- What is a Hysteresis Motor: Ultimate Guide

- Differences Between Motor and Engine

- Universal Motor: a Simple Guide to Construction, Types and Working

- Your Guide To The Working Principle Of DC Motor

- Working Principle Of DC Motor: 2022 Complete Guide

- DC Motor Efficiency: Calculation: Formula & Equation

- What is a Series Wound DC Motor?

- DC Motors vs Servo Motors: A Complete Comparison

- Separately Excited DC Motor

- The Difference Between DC Motor and Stepper Motor: Everything You Need To Know

- What are the Advantages of DC over AC?