Today in Linquip, we’re going to discuss everything about DC motors, their types, and applications. As you may know, a DC motor or a direct connection motor is referred to as any type of rotary electric motors that converts direct electrical energy into mechanical energy. There are four main types of DC motor, all of which are used for different applications. If you want to know everything about a DC motor, DC motor types, and their utilizations.

On Linquip’s website, you can find all the information you need about DC motor equipment and devices. At Linquip, we are happy to assist you with any questions you may have related to DC motors. For more information about DC motors, visit Linquip and explore the article “What Is DC Motor?“.

Are you searching for DC motor devices and equipment? Linquip offers a wide range of equipment for your DC motor applications. See lists of DC Motor Products Browse them online free of charge. Do you want to buy DC motor devices & equipment? Click here to get free access to every DC Motor Devices for Sale you may need. Need an up-to-date price list for DC motors? With Linquip, you can send inquiries to all reputable DC Motor Suppliers and receive quotes for free.”

⇒ View a List of DC Motor for Sale and Their Suppliers ⇐

What is a DC Motor?

It’s interesting to know that DC motors are everywhere. Unlike its bizarre name, direct connection motors are everywhere around us, and they’re making our lives much more comfortable. In a nutshell, any device that uses electricity to provide various motions is doing it using DC motor types.

Now that you know what a direct connection motor is let’s dive deeper into the concept and discuss the types of direct connection motors and their application in the industrial field.

How Many Types of DC Motor Are There?

There are four main types of direct connection motors:

- Permanent Magnet DC Motor

- Series DC Motors

- Shunt DC Motors

- Compound DC Motors

If you want to understand how direct connection motors work and what utilizations they have, you need to get familiar with their different types.

1. Permanent Magnet DC Motor

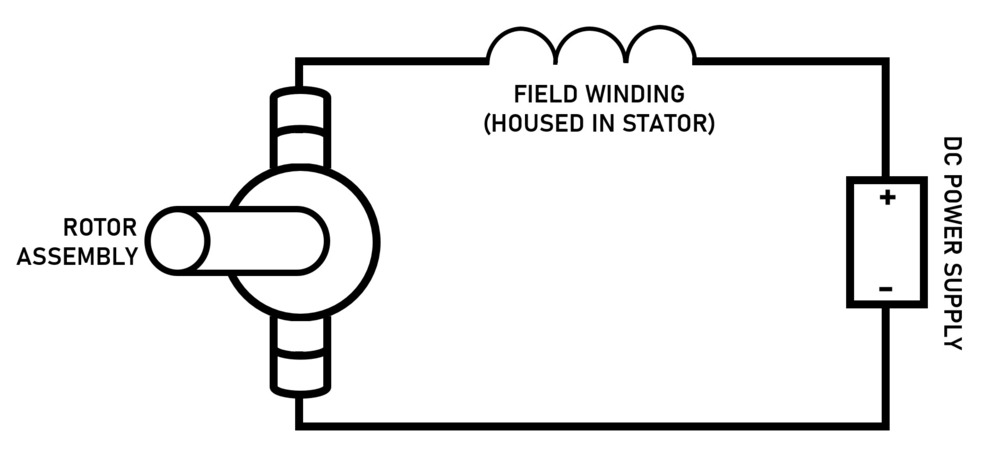

The permanent magnet motors work by a permanent magnet to make a field flux. A PM direct connection motor does not have a field winding on the stator frame. Instead, it uses permanent magnets to provide a magnetic field against which the rotor field interacts to produce torque.

This type of direct connection motor makes excellent starting torque, and it has good speed regulation.

2. Series DC Motors

In the series DC motors or series wound DC motors, the entire armature current flows through the field winding. Usually, this DC motor type creates a large amount of starting torque, but it can’t regulate speed, and even running with no load can damage it. Therefore, these limitations make series DC motors, not a good option for variable speed drive applications.

See All Series Wound DC Motors for Sale

3. Shunt DC Motors

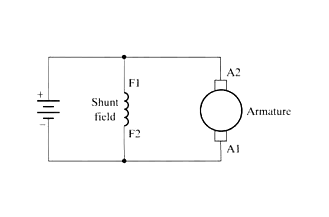

Shunt DC motors are a type of direct connection motors in which the shunt field winding is only parallel to the armature winding and not the series field winding. Shunt DC motors are also known as compound wound DC motors. Shunt DC motors provide excellent speed regulation, as the shunt field can be excited separately from the armature windings. This feature of shunt direct connection motors provides simplified reversing controls.

Read more about AssunMotor’s coreless brushless DC motor.

4. Compound DC Motors

Compound DC motors or compound wound motors have both series and shunt field windings. These types of motors offer good starting torque, but they may have control problems in variable speed drive applications. These motors can be connected to two arrangements: cumulatively and differentially. The cumulative type connects the series field to aid the shunt field, providing higher starting torque but less speed regulation. The differential type has good speed regulation and usually operates at a constant speed.

Various DC Motor Applications

In general, DC motors are used as variable speed drives and for the applications in which sever, torque variations occur. Now that you’re familiar with different DC motor types let’s get through their usages and applications.

Series DC motors are generally used where high starting torque is required, and speed variations are possible. These types of direct connection motors are, for instance, used in the traction system, cranes, air compressors, vacuum cleaners, sewing machines, etc.

Shunt DC motors are used for applications where you need constant speed, and the starting conditions are not severe. The shunt direct connection motors applications are in lathe machines, centrifugal pumps, fans, blowers, conveyors, lifts, waving machines, spinning machines, etc.

Compound wound motors are usually used where you need higher starting torque and relatively constant speed. The compound DC motors applications are in presses, shears, conveyors, elevators, rolling mills, heavy planners, etc.

What Are the Main Parts of a DC Motor?

DC motors are composed of the following components: a stator, a rotor, a yoke, poles, armature windings, field windings, commutator, and brushes. Many of its parts are similar to those in AC motors, but there are a few differences.

What are the Advantages of DC Motors?

Comparing with the AC motors that converts alternating current into mechanical power, DC motors have some advantages you might want to consider.

Generally, direct connection motors have higher starting torque than alternating current ones. This feature makes it easier to get things moving. The only problem of this feature is that you can’t start them unless they are under a load. If a DC motor doesn’t have a load to start, it can burn out fast.

The other advantage of various DC motor types is that they generate a speed-torque curve that’s more linear than the AC motors. This feature is actually due to the curve plotted between the torque and the motor’s speed, which explains the relationship between how fast the motor spins and how much torque it can generate.

The ability to control the speed is the other upper hand of direct connection motors. If you’re working with heavy load systems, the ability to control the speed becomes very crucial, and it determines whether you’ll end up with a successful job or a burned out motor. Therefore, DC motors are ideal for any job needing constant low-speed torque or variable torque.

Another important point to consider is that DC motors are easier to install compared to the AC motors. They also need less maintenance and are easier to repair. If your industrial types of equipment are set up to use DC motors, replacing a broken one with a DC motor is quick and easy. While replacing it with an AC motor will force you to redesign the whole motor circuit.

Final thoughts

In this article, we went through all the important points about direct connection motors. Different DC motor types offer you various applications, and you need to choose the ones which fit the most with your requirements.

If you want to buy a direct connection motor, apart from the DC motor price, you need to go through all the characteristics we discussed in this article and opt for one with awareness. You can always stay in touch with the Linquip team for further consultations. To do so, you can Sign Up on Linquip and get your exclusive consultation.

Download DC Motor Types PDF

It is possible to download a PDF document containing the content of this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- DC Motor Efficiency

- Series Wound DC Motor

- Series Wound DC Motor

- Separately Excited DC Motor

- Series DC Motors: A Comprehensive Guide

- The Good Guide to Types of Electric Motors

- A Full Explanation on Types of Servo Motors

- DC Motor Parts, Structure, Design and Advantages

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- Compound DC Motors: Everything You Should Know About DC Compound Motors

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- Working Principle Of DC Motor: Complete Guide

- Working Principle of Stepper Motor: Ultimate Guide

- DC Motor Efficiency: Calculation: Formula & Equation

- What is Gear Shaft? Clear Principle & Advantages

- AC Series Motor

- What is a Series Wound DC Motor?

- DC Motors vs Servo Motors: A Complete Comparison

- Difference Between Pump and Motor

- What is the Principle of Electric Motor: The Concise Answer

- What are the Advantages of DC over AC?

- The Simple Guide to Motor Efficiency: What It is and What to Do

- DC Motor Working Principles : The Most Compendious Reference

- Series DC Motors: A Comprehensive Guide

- 8 Different DC Motor Parts, Structure, Design and Advantages + PDF