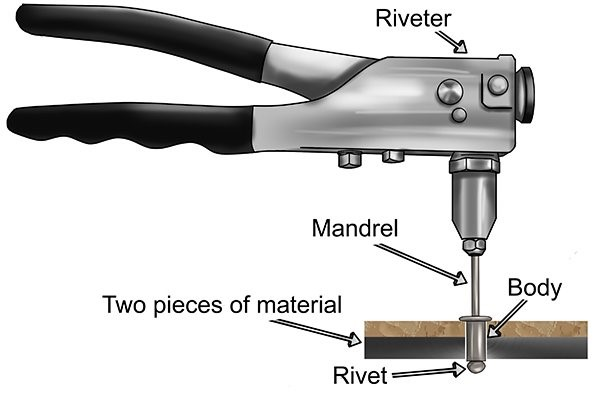

Types of Blind Rivets – A head and a hollow cylindrical pin (the “body”) make up a blind rivet, which is sometimes referred to as a pop rivet. The head of a mandrel, a long, thin pin with a depression in the middle, serves as a stop at the other end of the body from the rivet head. Blind rivets come in a variety of body and head designs. They are made from a variety of substances.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Rivets, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Rivets for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is a Rivet?

Because they can quickly and easily link two or more pieces of material, rivets are quite popular. A powerful, dependable choice that uses a rivet gun to deliver a secure solution. Basically, a rivet is made of two parts: a metal tube (body) and a pin (mandrel). Typically, the pin is longer than the tube and is intended to be drawn up through the tube, widening it as it does so. The material between the pin head and the setting head is secured as the body expands. The pin that was being utilized for lifting the body would eventually break and fall off.

There are many different types of rivets for practically any use, from attaching your home’s guttering with open-end standard rivets to using structural rivets in the vehicles we drive and the aircraft we fly. Steel, stainless steel (304 and 316 grade stainless), and aluminum are just a few of the metals that are used to make rivets. Many are also available in combinations of multiple metals, such as steel and aluminum. It’s nearly difficult to picture the modern world without pop rivets.

Working Principle of Rivets

In the building of machines and structures, rivets are a very important instrument. Drilling, punching, or inserting the rivets into a hole and deforming the tail are various methods of installing them. The most common riveting method involves drilling a hole in the component that will be fastened. This is due to how much easier and more widely available it is.

To properly attach the rivet, a hole that is 1.5 mm larger than the rivet’s diameter is bored into the material. The tail emerges at the other end with a distorted shape as soon as the rivet is inserted. The material is flattened when the rivet tail is pounded or smashed, which frequently causes the tail to unfurl or spread. It increased in size to nearly 1.5 times its initial size.

In other words, by hammering or tugging to break off the tail flatter on one end and produce a new head on the other head, you may construct a rivet the size of a dumbbell. The tail then assumes the form of a dumbbell. The joint has been riveted in this manner.

Various Types of Blind Rivets

In what follows, various types of blind rivets are described briefly.

9 Types of Blind Rivets include:

- Standard Blind Rivets

- Sealed Blind Rivets

- Peeled Blind Rivets

- Grooved Blind Rivets

- Multi-Grip Blind Rivets

- Soft Set Blind Rivets

- Dome Head Blind Rivets

- Large Head Blind Rivets

- Countersunk Head Blind Rivets

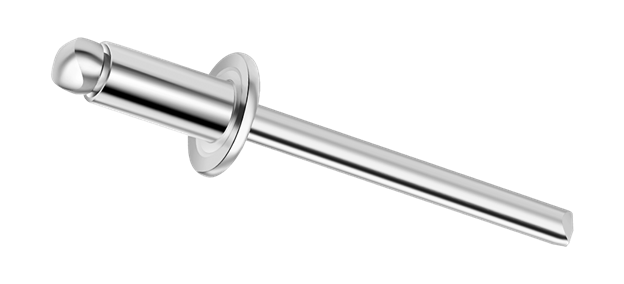

Standard Blind Rivets

Metal-to-metal fastening often involves the use of standard blind rivets. They have simple bodies and dome-shaped heads. The body of the rivet expands at its “blind” end when the mandrel is partially pulled through it, forming a second head to stably bind materials together. Automotive, metals, construction, electrical appliances, furniture, containers, air conditioning, and heating are just a few of the sectors that employ standard rivets.

Sealed Blind Rivets

This particular style of the blind rivet has a sealed end. Unlike other types of blind rivets, this one’s mandrel head is enclosed within the sealed body of the rivet and does not protrude from the end. In order to fasten metal to metal, sealed rivets do not permit liquids to enter or exit.

While the head of the rivet is sealed, the mandrel’s head rests inside the rivet’s body. This keeps liquid from entering or leaving the component. They are appropriate for usage in the metal, building, and automotive sectors. Additionally, they may be found in containers, furniture, air conditioning, and heating systems, as well as electrical gadgets.

Peeled Blind Rivets

Peeled rivets increase the diameter of the locking head, giving it a larger bearing surface (underside of head). The body enlarges as the mandrel is dragged through it, leaving a head with a flower-like form and four petals. The optimum application for this kind of rivet is joining metal to softer materials.

A head is formed by folding the sides (petals) of the rivet over, which secures the materials together. Peeled rivets function well in the construction business (plasterboard, coatings, and insulation) and may be used on trailers, plastic parts, electrical appliances, and upholstery (padded covering on furniture).

Grooved Blind Rivets

When installing softer materials like plastic and wood, this type of rivet’s body-encircling grooves provides tremendous holding power. For attaching metal to wood and metal to building supplies, including cement, bricks, and wood, grooved rivets are ideal.

The material is fastened together by the grooves on the rivet’s body that embeds into it. It is not necessary for the hole it enters to penetrate straight through the surface.

When the mandrel is pushed out of a grooved rivet, the rivet’s tail grows inside the material rather than forming a new head on the opposing side. As a result, the rivet’s head at one end grabs the object that is being attached to the material while the head at the other end grips the material with friction.

Construction, the metal sector, furniture production, electrical equipment, and injection-molded parts are the ideal applications for grooved rivets.

Multi-Grip Blind Rivets

Similar to regular rivets, multi-grip rivets also include indents on the rivet body. When the mandrel is dragged into the body, the indents enlarge and offer several grips. These rivets are used to join plastic to plastic and metal to metal.

Similar to regular rivets, multi-grip rivets also include indents on the rivet body. When the mandrel is dragged into the body, the indents enlarge and offer several grips. These rivets are used to join plastic to plastic and metal to metal.

Soft Set Blind Rivets

Standard rivets and soft rivets are interchangeable. The body and mandrel, on the other hand, are made of a softer metal, usually an alloy of aluminum. The mandrel delivers the proper amount of pressure to secure fragile materials without causing harm since it breaks off with significantly less force than other types of rivets.

These rivets may be used to secure soft materials with little resistance to metal or plastic, as well as metal to wood, plastic, fiberglass, and plastic to plastic. Soft rivets can be utilized in building, furniture, packing, plastic parts, and containers.

Dome Head Blind Rivets

Except for highly smooth and brittle materials like plastic, the dome head’s ample bearing surface allows it to be used to secure a range of materials.

This is so that softer materials won’t be damaged, as this style of the head puts greater pressure closer to the drilled hole. A bearing surface is when two materials come into contact. In this instance, the portion of the rivet that makes contact with the material being secured is the region under its head.

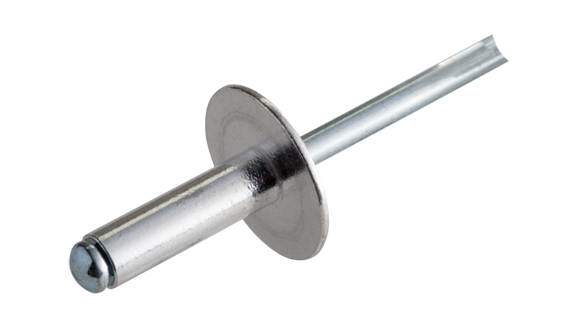

Large Head Blind Rivets

When compared to a dome head rivet, the big head gives double the bearing area. Attaching fragile or soft components to strong support materials offers excellent resistance.

Countersunk Head Blind Rivets

A countersunk head maintains a level surface by fitting into the material without projecting.

Materials Used for Rivets

Rivets may be made from a variety of metal sources. They consist of stainless steel, copper, brass, aluminum, and steel. To meet their demands, designers and producers pick these various materials.

Rivets now have a limitless range of uses because of these abundant materials. Therefore, it is wise to choose a rivet-making material that complements the characteristics of the components you intend to link.

Steel

Applications requiring rivets can benefit from steels with low carbon characteristics. This is because it can clinch or fits snugly in the application. In contrast to hard high-carbon steel rivets, it is also incredibly adaptable and flexible. High carbon steels have a worse moldability and require more material to produce rivets.

Stainless Steel

The stainless steel rivets are exceptionally tough, durable, and deterioration-resistant. These rivets are used in the aerospace, power generation, and locomotive sectors. Because they can withstand corrosion, these stainless rivets are used.

Aluminum

Another type of metal with a well-known use for rivets and fasteners is aluminum. It is renowned for both its gentleness and lightness. Aluminum is a versatile material that gives a high level of degradation resistance. Aluminum is also extremely malleable, making it possible to build intricate component arrangements readily.

Brass

Flexible, low-friction, and elastic describe brass as a material. It is incredibly strong and tarnish-resistant, which is pretty intriguing. Brass cannot produce sparks because of its characteristics. Brass rivets are the type that works well with gas appliances due to their characteristics.

Copper

In both look and use, copper is a flexible substance. It is remarkably good at transferring heat and electricity. Because copper is such a good conductor of electricity, copper rivets are frequently used in electrical and plumbing appliances.

Application of Rivets

Rivets in Aerospace

Initially, projects for aviation machining should be created of reliable, sturdy, and solid materials. Unfortunately, if workers don’t properly tighten these hefty and robust components together, everything might come apart. Therefore, just like brazing, welding, and bolting, riveting is crucial for the manufacturing of airplanes.

In order to achieve the fundamental goal of having excellent alignment and the strongest possible combination of elements linked together, riveting is crucial. Due to the difficulties of soldering aluminum alloys, rivets are used to secure them together. Additionally, riveting guarantees order and strength, allowing for lower weight in airplanes. Reaching the far end of a constricted structure may be challenging or practically impossible while working on an airplane. The only solution, in this case, is riveting.

Jewelry

Both expert and novice jewelry makers use riveting as a cold joining technique in their production processes. By employing some instructional videos, fundamental metal forming abilities, and certain common equipment, jewelry makers may quickly apply riveting to establish cold connections. Jewelry makers may now attach metallic components without necessary soldering by using riveting.

Joints

When it comes to building, Rivet is renowned for its effectiveness. It is a complex connector that makes it simple to join various components of a machine or construction. This fastener makes it easier to attach lockers, wooden shelves, and cupboards. Any wooden substance may be connected by using rivets as joints.

Rivets act as a junction that is far more dependable and long-lasting than screws and lines. For instance, furniture that has joints made of rivets is likely to survive longer. This is because, over time, the rivets held the furniture in place.

Building a Home

Perchance should carefully consider what you have inside and outside of your house. One or two rivets that you haven’t seen previously are probably waiting for you. The truth is that they probably exist in your immediate surroundings. The fiberglass roofing can use these rivets. Therefore, rivets assist in holding the glass together if your home has this style of roofing.

Additionally, rivets are a useful element while building gutters. They are a more reliable option than nails for joining metal sheets. More importantly, riveting is used to create structures such as hanging straps, wind barriers, doors, and window shades.

Download Types of Blind Rivets PDf

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 13 Types of Adjustable Wrench: Clear Guide

- What Are Blind Rivets and How Does It Work? (Comprehensive Guide)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- What Is The Difference Between A Blind Rivet And A Pop Rivet?

- 4 Types of Solid Rivets + Working Principle

- What Are Solid Rivets And How Do They Work? (Clear Guide)

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- What is Pop Rivets and How Does It Work? (A Comprehensive Guide)

- 13 Types of Rivets + Applications & Working Principle