We have already covered the topic of direct current motors in a separate article, and there are many articles about its different types on Linquip, all of which you can access with a simple search. But in this article, we specifically intend to discuss how it works and the rules by which this type of motor is designed will be deeply delved into. To better understand the DC motor working principles we have provided information about the purposes of creating and uses of these engines and their types, as well as their advantages and disadvantages we may encounter.

One of the earliest electric motors that converted direct current electrical energy to mechanical energy was the DC motor. A DC motor is a crucial piece of industrial equipment. DC Motors are available from a variety of Suppliers And Companies, as well as manufacturers and distributors, and there are many DC Motors For Sale on Linquip.

Linquip’s website has a complete selection of DC motor services that will meet all of your needs. Linquip can connect you with a number of industrial DC motor service suppliers and experts who can help you. Linquip provides a list of DC Motor Specialists who can help you test your equipment.

Linquip has gathered all the available information on this topic to eliminate the need for you to read scattered content. Stay with us till the end. To begin with, let’s look at what a DC motor is and what it does for us.

What Is a DC Motor?

In this section, and before we enter the main subject of DC motor working principles, it is vital to know that what a DC motor does and what parts are involved to run a device such as DC motors.

A DC motor is one of the first electric motors designed to convert direct current electrical energy to mechanical energy. It is one of the greatest devices that humans invented and since then, it has amazingly revolutionized our lives. This rotary electrical machine occupied different types, all of them contain almost the same components that cooperate based on either the mechanism of electronic or the mechanism of electromechanical that is responsible for changing the direction of current in the motor.

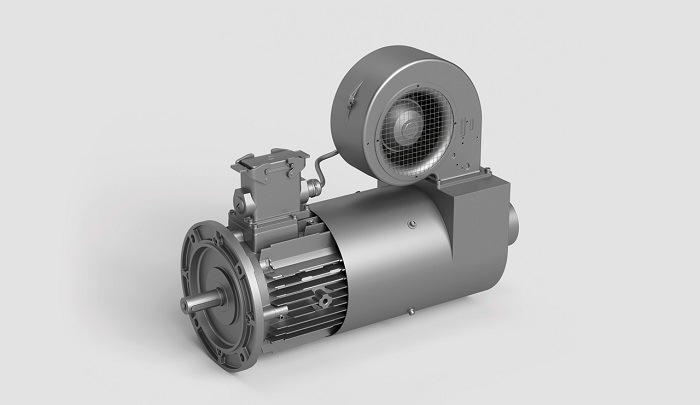

A DC motor is made up of a stator, an armature or a rotor, and a commutator with brushes. These are main components and are included in all the DC motors. If we want to explain very briefly how this type of engine works, we must say that the polarity opposition between the two magnetic fields of the motor causes it to turn. These motors may be the simplest motors available in terms of construction and performance, but they have a wide range of uses, including those used in home appliances such as electric razors and those used in a variety of industries.

Brief on DC Motors’ Various Types

In the previous section, we discussed what a DC motor does and for what purpose it was invented. Later, we briefly mentioned how it functions overall. As we noted before, this type of motor has some subcategories the most common-in-used of which are series, shunt, permanent magnet, brushless, and compound DC motors. Since we have dealt with each of these types of DC motors in separate articles. In the following, we will just shortly mention them for the remembrance.

-

Permanent Magnet Motors

Permanent Magnet Motors, also known as PMDC motors, are one the DC motors that use a permanent magnet to make a field flux. This type of DC motors possesses a great starting torque with good speed regulation. With limited torque it has, typically appliances with low horsepower use permanent magnet motors.

-

Shunt Motors

the field of shunt motors is connected in parallel with the armature windings. This type of motors provides a great speed regulation due to the fact that the shunt field can be excited separately from the armature windings. additionally, shunt motors also provide simplified reversing controls.

-

Series Motors

A series motor is made up of a field wound with some turns of a wire which carries the current of the armature. Just like permanent motors, series motors offer a large amount of starting torque. But unlike permanent motors, series motors cannot regulate speed. Besides, if series motors run with no load, it can be so hazardous. These limitations make series motors unsuitable for variable speed drive applications.

-

Compound Motors

Compound motors have a shunt field which is separately excited, just like shunt DC motors. compound DC motors are alike permanent and series motors, in terms of offering good starting torque but they have some problems in speed regulation in variable speed drive applications.

An Elaboration on DC Motors’ Working Principle

Now that we are accustomed to the purpose and the most-used types of DC motors, It will be easier to understand on what basis and according to what rules and regulations these motors work.

DC motors work on the principle of electromagnetism that for the first time Faraday introduced. Faraday’s principle of electromagnetism says that a current-carrying conductor faces a force when it is placed in a magnetic field. On the other hand and according to Fleming’s Left-hand rule, the motion of the conductor is always in a direction that is perpendicular to the current and the magnetic field.

As we mentioned before, a better understanding of the working of DC motor needs us to know about all the details in the construction. The armature is the rotating part that is placed between the north and south pole of the permanent or electromagnet and the stator is their stationary part whose magnetic fields are in interaction with the magnetic field of the rotor or the armature.

The armature coil consisting of the commutator and brushes is connected to the DC supply. The commutator turns the AC induced in the armature into DC and the brushes move this current from the rotating part of the motor to the stationary external load.

How Does a DC Motor Work?

In the previous section, we found DC motors work on the basis of Faraday’s principle of electromagnetism and Fleming’s Left-hand rule. In this section, we show you how exactly a DC motor works and how its components cooperate to run this device.

The stator of a DC motor enjoys a stationary set of magnets and a coil of wire with a current running through it to produce an electromagnetic field aligned with the center of the coil. To concentrate the magnetic field One or more windings of insulated wire are wrapped around the core of the motor.

The windings of insulated wire are connected to a rotary electrical switch that is called a commutator, applying an electrical current to the windings. The commutator allows each armature coil to be energized in turn, creating a steady rotating force.

To create this steady rotating force called also torque the coils of the armature are turned on and off in a sequence that consequently a rotating magnetic field is generated that interacts with the different fields of the stationary magnets in the stator.

This interaction between the rotating magnetic field and field of stationary magnets in the stator finally causes it to rotate. These key operating principles of DC motors allow them to convert the electrical energy from direct current into mechanical energy through the rotating movement, which can then be used for the propulsion of objects.

Advantages and Disadvantages of DC Motors

There is a wide range of DC motors in different dimensions and sizes, suitable for different needs. Small ones can be used in toys, tools, and home appliances, and larger ones are used in the elevator and hoists and propulsion of electric vehicles and industrial appliances.

Although AC motors decreased the selling amount of DC motors on account of simple generation and transmission with fewer losses to long distances, needing less maintenance and can be operated in explosive atmospheres, DCs still are used in where ACs can’t fulfill the needs. DCs have their unique features and importance in industries that make up for lots of other advantages that AC motors have over them.

Above we mentioned some of the disadvantages of DCs in comparison to ACs. Below are some of the most prominent advantages of DC motors:

- They are suitable for low-speed torque

- They have adjustable speed

- They offer a wide range of speed control both below and above the rated speed

- They have a very high and strong starting torque

- They are used in appliances such as electric trains and cranes having overwhelming burdens in the beginning conditions

- They are more affordable

- Their maintenance is easy and takes little to no time

Conclusion

in this article, we tried to give you essential and comprehensive information about the DC motor working principles. we talked about the design and construction of DC motors, what they do, and for what purpose they were basically designed. Besides, for better understanding, we brought some basic pieces of information about the different types of DC motors. Then, we reached the section we talked about the working principle and the functionality of this type of motor. In the end, we listed some of the features, disadvantages, and disadvantages of this type of motor for you and mentioned where this type of motor is commonly used.

If you have any experience of using different types of commutator motors, we will be very glad to have your opinions in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Download DC Motor Working Principles PDF

Read More In Linquip

- All About DC Motor Types and Their Applications

- What is the Working Principle of DC Generator?

- DC Motor Efficiency: Calculation: Formula & Equation

- DC Motor Parts, Structure, Design and Advantages

- How Does a Brushless Motor Work: A Full Explained Guide

- Compound DC Motors: Everything You Should Know About DC Compound Motors

- The Simple Guide to Motor Efficiency: What It is and What to Do

- What is a Series Wound DC Motor?

- DC Motors vs Servo Motors: A Complete Comparison

- Separately Excited DC Motor

- The Difference Between DC Motor and Stepper Motor: Everything You Need To Know

- What are the Advantages of DC over AC?

- A complete Guide to The Difference Between Stepper Motor and DC Motor

- 4 Different DC Motor Types and Their Applications

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- Series DC Motors: A Comprehensive Guide

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- 8 Different DC Motor Parts, Structure, Design and Advantages + PDF