A temperature transducer is employed to measure the temperature of a physical object. Ordinarily, a transducer is nothing but transforming a physical quantity into electrical energy. Thus, a temperature transducer is an instrument used to convert the thermal energy of the substances into electrical form. In other words, it is a piece of electrical equipment applied for automated measuring of temperature. The latest purpose of the temperature transducer is to measure the heat of the material in a readable format.

Principle Features of Temperature Transducers

Although there are various types and applications for temperature transducers, the basic principle and features of them are quite similar, which can be summarized as the following:

- The input to a temperature transducer is invariably the thermal quantities

- They regularly transform the thermal amount into an electrical one

- They are typically utilized for the determination of the temperature and heat flow

A Temperature Transducer is a device that transforms thermal energy into physical quantities including mechanical energy, pressure, and electrical impulses, among other things. A temperature Transducer is a Vital Component of Using Industrial Tools. Temperature Transducers are available from a variety of Suppliers and Companies, as well as various manufacturers and distributors, and there are several Temperature Transducers for sale on Linquip.

A full list of Temperature Transducer services is available on the Linquip website, which covers all OEM fleets. Linquip vendors can assist you with this. Please contact Temperature Transducer Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

Basic Plot of a Temperature Transducer

The fundamental design of temperature transducers is provided below:

Sensing Element

The sensing part in a temperature transducer is the element whose characteristics vary with temperature change. As the temperature varies, the corresponding difference happens in particular properties of the component. For instance, in a Resistance Temperature Detector (RTD), the sensing component is the Platinum metal.

Acceptable restrictions for determining the sensing component can be compiled as the following:

- The variation in the material unit resistance per unit change in temperature should be sufficiently significant.

- The material must have a large resistivity so that a minimum volume of a substance is employed for its manufacture.

- The material must have a continuous and enduring association with temperature.

Transduction Element

A transduction element is an element that converts the output of the sensing component into electrical quantity. The variation in the feature of the sensing component performs as the output for it. It measures the variation in the property of the sensing component. The outcome is then calibrated to produce output, representing the change in the thermal quantity. For example, in the thermocouple, the potential diversity generated across the two terminals is measured by a voltmeter. The magnitude of voltage generated after calibration provides the idea of temperature change.

Types of Temperature Transducers

From a general perspective, temperature transducers can be classified as contact and non-contact temperature transducers. In contact types, the sensing component is in direct contact with the substance; hence, they utilize the heat conduction mechanism to transfer thermal energy. In a non-contact transducer, the element is not in direct contact with the thermal source, which means non-contact temperature transducers employ the convection mechanism for heat transfer. For more information on various types of heat transfer, click here.

Based on the function and structure of the sensor, there are various types of temperature transducers, which can generally be classified into the following categories:

- Thermistor

- Resistance Thermometers

- Thermocouples

- Integrated Circuit Temperature Transducers

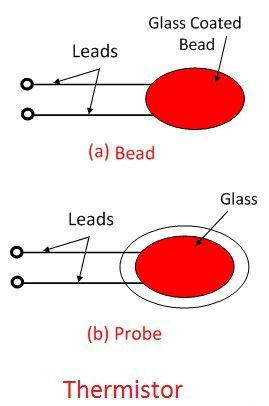

Thermistor

The word thermistor is a summarized form of “Thermal Resistor”. As the name implies, it is a device in which resistance varies with the temperature change. They are extensively employed for the measurements of the temperature due to their high sensitivity. They are regularly called the ideal temperature transducer. Thermistors are commonly comprised of a mixture of metallic oxides.

Characteristics of Thermistors

Thermistors have various types and applications; however, they have some common characteristics as follows:

- They have a “Negative Thermal Coefficient”, i.e., the thermistor resistance diminishes with an increment in temperature.

- They are produced from semiconductor materials.

- They are generally more sensitive than “Thermocouples” and “Resistance Thermometers”.

- Their resistance extends within 0.5 Ω to 0.75 MΩ

- They are generally employed in applications with a temperature range between -60 oC to 15 oC.

Applications

Some most important applications of thermistors are as the following:

- They can be utilized as current-limiting devices for circuit security as replacements for fuses.

- They can be employed as timers in the degaussing coil circuit of most Cathode-ray tube (CRT) displays.

- They can be employed as a heater in the automotive industry to produce additional heat inside the cabin with a diesel engine.

- They can also be utilized in the protection circuits of lithium batteries.

- They can be used as a resistance thermometer for very low-temperature measurements in the order of 10 K.

- They are also employed as sensors in automotive applications to monitor fluid temperatures like the cabin air, engine coolant, engine oil temperature, or external air, and supply the relative readings to regulate units like the ECU.

- Thermistors are also regularly used in modern digital thermostats and monitor battery packs’ temperature during charging.

- During the purchaser appliance industry for estimating temperature. Toasters, freezers, refrigerators, hairdryers, etc., depending on thermistors for precise temperature control.

- They are used to determine the temperature profile inside the sealed hole of a convective (thermal) inertial sensor.

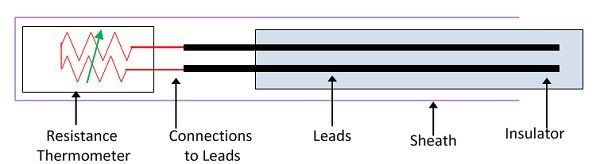

Resistance Thermometers

Resistance Temperature Detectors (RTDs) are another sort of temperature transducer. RTD’s are relatively high accuracy temperature sensors fabricated from high-purity conducting metals, such as copper, platinum, or nickel, bound into a coil. Their electrical resistance varies similarly to that of the thermistor corresponding to the temperature change.

Main Characteristics of RTD’s

Common characteristics of RTDs are as the following:

- They are profoundly sensitive and relatively affordable compared to thermocouples and thermistors.

- They are able to measure the temperature in the range of -182.96 oC to 630.74 oC.

Element types

The three principal divisions of RTD sensors are thin-film, wire-wound, and coiled elements. Although these types are most extensively employed in industry, other more unusual shapes are employed; for instance, carbon resistors are utilized at ultra-low temperatures (−273 °C to −173 °C).

Carbon resistor elements

They are affordable and extensively employed and have very reproducible outcomes at low temperatures. They are the most stable form at shallow temperatures. They commonly do not experience significant strain gauge or hysteresis effects.

Strain-free elements

This type uses a wire coil minimally maintained within a sealed housing supplied with an idle gas. These sensors work up to 961.78 °C and are employed in the SPRTs that define ITS-90. They consist of platinum wire loosely coiled over a support structure, so the element is free to expand and engage with temperature. They are very sensitive to shock and shake, as the loops of platinum can sway back and forth, creating deformation.

Thin-film elements

These types have a sensing component created by depositing a skinny layer of resistive material, typically platinum, on a ceramic substrate. This film is then spread with epoxy or glass that assists preserve the deposited film and also serves as a strain relief for the outer lead wires. The disadvantages of this type are that they are not as durable as wire-wound or coiled types.

Wire-wound elements

These types can have higher accuracy, particularly for broad temperature ranges. The coil diameter presents a trade-off between mechanical stability and enabling expansion of the wire to minimize strain and significant drift. The sensing wire is bound around an insulating mandrel or core. The winding core material’s thermal expansion coefficient is agreed to the sensing wire to depreciate any mechanical strain.

Coiled elements

These types of elements have widely replaced wire-wound components in the industry. This design has a wire coil that can extend freely across temperature, kept in position by some mechanical support, allowing the coil to maintain its shape. This “strain free” design enables the sensing wire to extend and contract-free of influence from other materials; in this regard, it is similar to the SPRT, the principal standard upon which ITS-90 is based while presenting the stability essential for industrial application.

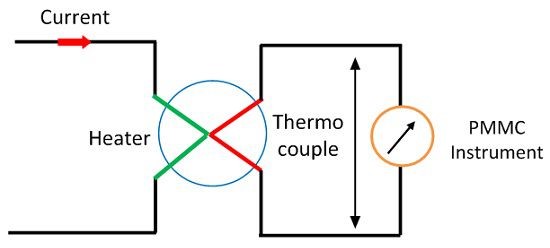

Thermocouples

Thermocouples are a type of temperature transducers consisting of two junctions of different metals, such as constantan and copper, welded together. One junction is maintained at a fixed temperature named the reference (cold) junction, and the other one is the measuring (hot) junction. This temperature difference among two junctions produces a voltage generated across the junction utilized to measure the temperature. The phenomenon is designated as the Seebeck effect, in which a temperature gradient is formed along the conducting wires creating an electromagnetic field (EMF). The producing voltage from the thermocouple is a function of the temperature variations.

Main Characteristics of Thermocouples

Despite differences among various types of thermocouples, their characteristics generally lie among the following items:

- Their main advantage is the capability of vast temperature range measurement compared to RTDs and thermistors (-200 oC to over +2000 oC).

- They are the Active Transducers, which means they do not require any external source to measure temperatures like Thermistors and RTDs.

- They are more affordable than both Thermistors and RTDs.

They have lower accuracy compared to Thermistors and RTDs; thus, generally, they are not utilized for high accuracy applications.

Thermocouples types

Specific combinations of alloys have become common as industry standards. The determination of the combination is directed by expense, availability, accessibility, melting point, chemical characteristics, endurance, and production. Several types are best befitted for diverse applications. They are regularly chosen based on the temperature range and sensitivity required. Thermocouples with low sensitivities (B, R, and S types) have correspondingly lower resolutions. Other selection criteria comprise the chemical inertness of the thermocouple substance and whether it is magnetic or not. Regular thermocouple types are listed below, with the positive electrode first, followed by the negative electrode.

- Nickel-alloy thermocouples

- Type E

- Type J

- Type K

- Type M

- Type N

- Type T

- Platinum/rhodium-alloy thermocouples

- Type B

- Type R

- Type S

- Tungsten/rhenium-alloy thermocouples

- Type C

- Type D

- Type G

Applications

Thermocouples are proper for measuring over a broad temperature range, from −270 °C up to 3000 °C (for a slight time, in an inactive atmosphere). Applications incorporate temperature measurement for furnaces, diesel engines, gas turbine exhaust, other manufacturing processes, and fog devices. They are few suitable for applications where fewer temperature variations require to be measured with high accuracy, for instance, the range 0–100 °C with 0.1 °C accuracies. For such applications, thermistors, silicon bandgap temperature sensors, and resistance thermometers are more proper.

Why Do We Use Temperature Transducers?

When dealing with severe heat, risks, or inaccessible measurement sites, temperature sensors are used to guarantee that a process is either remaining within a specified range, providing safe usage of that application, or satisfying a mandated requirement.

Integrated Circuit Temperature Transducers

Integrated Circuit Temperature transducers are the type of transducers that employ the temperature sensing component with solid electronic circuits as a combination for the temperature measurement.

They generally have the following types:

- LM 335 – it gives an output of 10 mV/oK

- LM 34 – it renders an output of 10 mV/oF

- AD 592 – it provides a current output of 1µA/oK

Main Features of Integrated Temperature Transducers

At what follows, the main features of Integrated Temperature Transducers are summarized:

- They are linear temperature transducers

- They are very affordable

- They have a tiny operating range between 0 – 200 oC, which is their primary drawback.

Download Temperature Transducer PDF

You can click here to explore more about temperature transducers.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip :

- Types of Sensors Detectors/Transducers: An Entire Guide

- Resistive Transducer: Working Principle & Example

- Photoelectric Transducer: Application & Working Principles

- What Is a Pressure Transducer? A Simple Descriptive on the Definition, Working Principle and Considerations

- Important Detailed Information About The Types of Transducers

- Pressure Transducer: Definition, Working Principle, and Types

- Active Transducer : All You Should Know About

- Transducer vs. Sensor: Basic Differences & Advantages of Them

- Temperature Transducer: Definition, Working Principle, and Types

- Piezoelectric Transducer and Its Impressive Applications in Electric Circuits

- What are the Main Benefits of an Ultrasonic Transducer?

- All You Need to Know about Transducer

- Temperature and Humidity Sensors: An Ultimate Guide

- Temperature Sensors: Types, working principle & Practical Applications

- Types of Temperature Sensor and Their Application

- 10 Types of Molding Machinery + PDF (Clear Guide)

- 3 Common Types of Electrical Connectors (Clear Guide)

- Types of Sensors Detectors/Transducers: An Entire Guide

- Top Bearing Suppliers in USA & Worldwide

- 15 Types of Electrical Power Connectors (Clear Guide) + PDF

- The 8 Best Circuit Breaker Locators

- The 10 Best Mini/Benchtop Milling Machine

- 10 Best CNC Machines & Routers for WoodWorking

- The 8 Best Rust Converter (Review Guide)

- Top USA and International Semiconductor Manufacturers

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide