Types of Capacitors – Capacitors come in a variety of shapes, sizes, lengths, and girths, as well as a variety of materials. At least two electrical conductors (referred to as “plates”) are separated by an insulating layer in each of them (called the dielectric). Many typical electrical gadgets utilize capacitors as part of their electrical circuits.

Capacitors, along with resistors and inductors, are considered “passive components” in electrical equipment. Although integrated capacitors are the most frequent in terms of absolute numbers (e.g., in DRAMs or flash memory architectures), this article focuses on the many types of discrete capacitors.

Small capacitors are utilized in electronic devices to link signals between stages of amplifiers, as elements of electric filters and tuned circuits, and to smooth rectified current in power supply systems. Larger capacitors can be used for energy storage in strobe lights, as components of some types of electric motors, and for power factor adjustment in AC power distribution systems, among other purposes. Adjustable capacitors are widely utilized in tuned circuits since standard capacitors have a fixed capacitance value. Depending on the needed capacitance, working voltage, current handling capability, and other features, different types are used.

What is a Capacitor

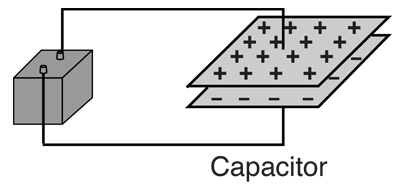

The capacitor is a passive component that stores electrical energy in the form of a magnetic field. Capacitance is the term for the capacitor’s effect. It consists of two closely spaced conductors separated by a dielectric substance. When the plates are linked to the power, the electric charge builds up on the plates. The positive charge is accumulated on one plate, while the negative charge is accumulated on the other.

Capacitance is the term used to describe the effect of a capacitor. While there is some capacitance between any two electrical conductors in close proximity to a circuit, a capacitor is a component that is specifically designed to add capacitance to a circuit. Traditionally, the capacitor was known as a condenser or condensator. Many languages continue to use this term and its cognates although English is one notable exception. Practical capacitors come in a variety of shapes and sizes, and there are many different types of capacitors in use. A dielectric media separates at least two electrical conductors in most capacitors, which are usually metallic plates or surfaces. A foil, thin sheet, sintered metal bead, or electrolyte can all be used as conductors. The capacitor’s charge capacity is increased by the nonconducting dielectric. Glass, ceramics, plastic film, paper, mica, air, and oxide layers are all common dielectric materials.

Many typical electrical gadgets utilize capacitors as part of their electrical circuits. An ideal capacitor, unlike a resistor, does not dissipate energy, yet real-life capacitors do. When an electric potential difference (voltage) is implemented across the capacitor’s terminals, such as when a capacitor is attached across a battery, an electric field begins to develop across the dielectric, creating a net positive charge to accumulate on one plate and a net negative charge to collect on the other. There is no current passing through the dielectric. The source circuit, on the other hand, has a charge flow. The current through the source circuit stops if the state is sustained for a long time. When a time-varying voltage is supplied across the capacitor’s leads, the source is subjected to a continuing current due to the capacitor’s charging and discharging cycles.

Theory of Operation

The capacitor is a passive component that stores electrical energy in a magnetic field. Capacitance is the term for the capacitor’s effect. It consists of two closely spaced conductors separated by a dielectric substance. When the plates are linked to the power, the electric charge builds up on the plates. The positive charge is accumulated on one plate, while the negative charge is accumulated on the other.

Two conductors are separated by a non-conductive area in a capacitor. A vacuum or an electrical insulator substance known as a dielectric can be used as the non-conductive zone. Glass, air, plastic, paper, ceramic, and even a semiconductor depletion are chemically similar to the conductors are examples of dielectric media. According to Coulomb’s law, a charge on one conductor exerts a force on the charge carriers within the other conductor, attracting opposite polarity charges and repelling similar polarity charges, resulting in the formation of an opposite polarity charge on the other conductor’s surface. On their opposing surfaces, the conductors carry equal and opposite charges, and the dielectric generates an electric field.

An ideal capacitor is described by a constant capacitance C, in farads in the SI system, determined as the ratio of the positive or negative charge Q on each conductor to the voltage V among them:

C=\frac{Q}{V}

One farad (F) capacitance means that one coulomb of charge on each conductor results in a voltage of one volt across the device. The opposite charges on the conductors (or plates) attract one another due to their electric fields, permitting the capacitor to retain more charge for a given voltage than when the conductors are separated, resulting in a larger capacitance.

Charge build-up in practical devices can alter the capacitor mechanically, causing its capacitance to change. Capacitance is characterized in this situation in terms of incremental changes:

C={\frac {\mathrm {d} Q}{\mathrm {d} V}}

Types of Capacitors

The following are the various types of capacitors:

- Electrolytic Capacitor

- Paper Capacitor

- Mica Capacitor

- Non-Polarized Capacitor

- Film Capacitor

- Ceramic Capacitor

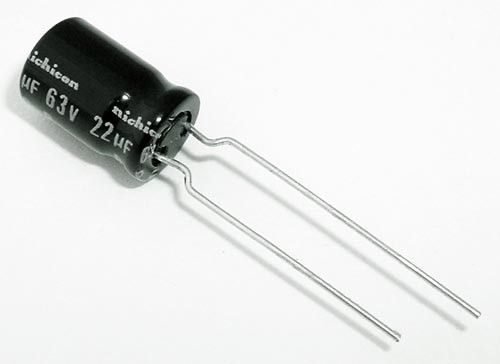

Electrolytic Capacitor

Electrolyte capacitors are typically utilized when large capacitor values are required. A thin metal film layer is utilized for one electrode, while a semi-liquid electrolyte solution in jelly or paste is applied for the second electrode (cathode). The dielectric plate is a thin layer of oxide that is electrochemically produced in manufacturing with a film thickness of fewer than ten microns.

Because this insulating layer is so thin, it is possible to build capacitors with a big capacitance value for a tiny physical size and a short distance between the two plates. The majority of electrolytic capacitors are polarized, which means that DC voltage is provided to the capacitor terminal and the polarity must be right.

If the positive is connected to the positive terminal and the negative is connected to the negative terminal, the insulating oxide layer will be broken, resulting in irreparable damage. The polarity of all polarized electrolytic capacitors is clearly marked with a negative sign to indicate the negative terminal, and the polarity must be followed.

Electrolytic capacitors are commonly used in DC power supply circuits because of their huge capacitance and small ripple voltage reduction. Coupling and decoupling are two applications for electrolytic capacitors. Electrolytic capacitors have a low voltage rating due to their polarization, which is a drawback.

Paper Capacitor

Paper was applied in between the two foils of the capacitor in the beginning, however, these days, different materials such as plastics are utilized; therefore, it is referred to as a paper capacitor. The paper capacitor has a capacitance range of 0.001 to 2.000 microfarads and a voltage range of up to 2000V.

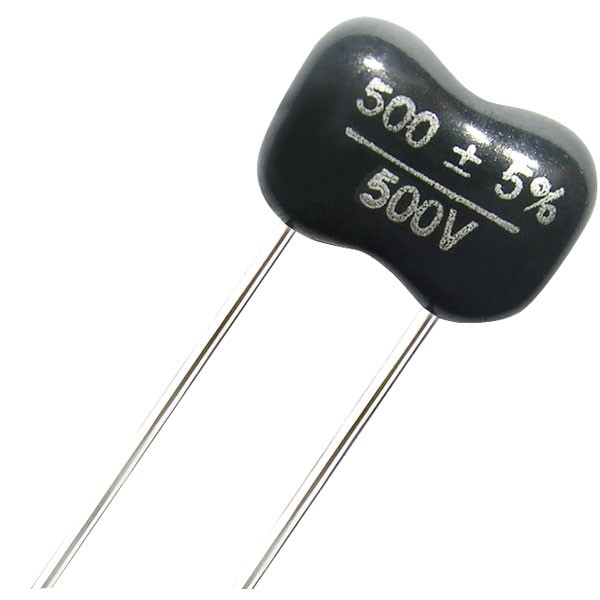

Mica Capacitor

The silver mica capacitors use the dielectric, which is made up of a set of natural minerals. Clamped capacitors and silver mica capacitors are the two types of mica capacitors. Because of their poor performance, clamped mica capacitors are deemed outdated. The silver mica capacitors are made by sandwiching mica sheets with metal coatings on both sides and encasing them in epoxy to protect them from the elements. The mica capacitors utilized in the design require a tiny, stable, and reliable capacitor.

Mica capacitors are low-loss capacitors that are utilized at high frequencies. They are chemically, electrically, and physically stable due to their particular crystalline structure binding and layered structure. Muscovite and phlogopite mica are the most often utilized micas. The electrical qualities of Muscovite mica are superior, and the other mica has a high-temperature resistance.

Non-Polarized Capacitors

Plastic foil nonpolarized capacitors and nonpolarized electrolytic capacitors are the two types of nonpolarized capacitors.

The plastic foil capacitor is non-polarized by nature, and electrolytic capacitors are often two capacitors in series, back to back, resulting in a nonpolarized capacitor with half capacitance. The AC applications in series or parallel with the signal or power supply are required for the nonpolarized capacitor.

Speaker crossover filters and a power factor correction network are two examples. A significant AC voltage signal is placed across the capacitor in these two applications.

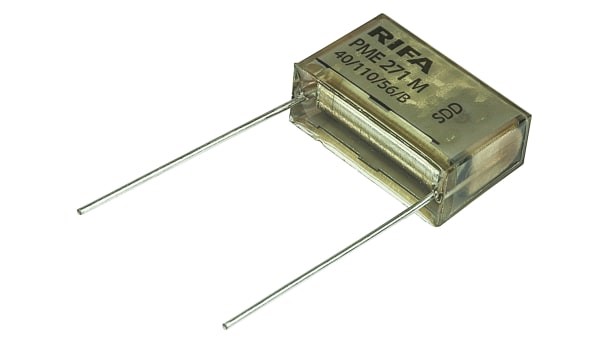

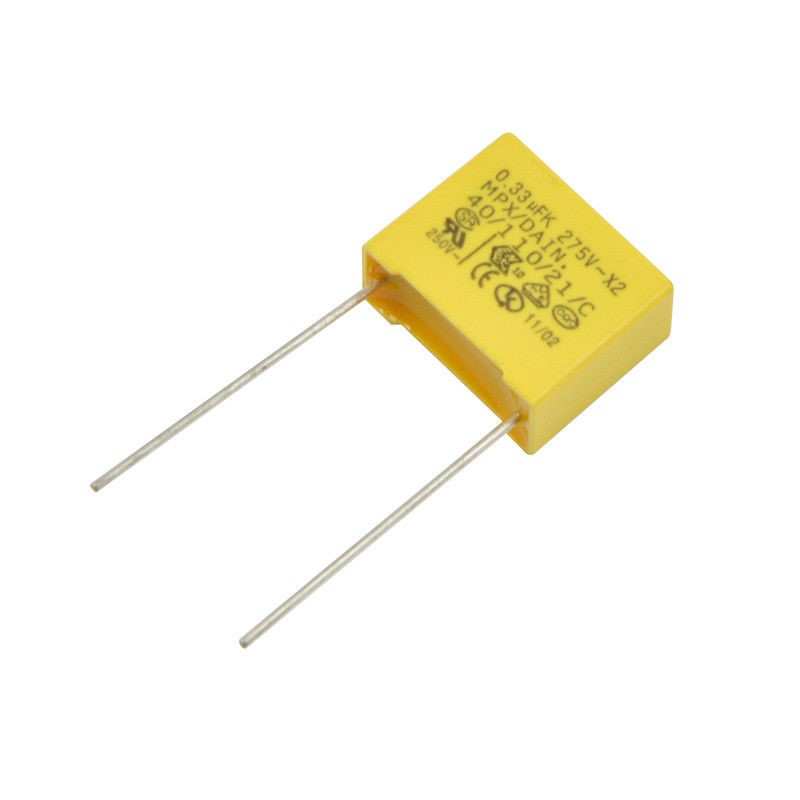

Film Capacitor

Film capacitors are capacitors with a thin plastic dielectric as the dielectric. Using a sophisticated film drawing method, the film capacitor is made exceedingly thin. If the film is made, it can be metalized depending on the capacitor’s qualities. The electrodes are added and assembled to guard against the environmental factor.

Polyester film, polypropylene film, metalized film, PTE film, and polystyrene film are some of the numerous types of film capacitors available. The material used as a dielectric is the main distinction between various capacitor types, and dielectrics should be chosen carefully based on their qualities. Film capacitors are used for their stability, low inductance, and inexpensive cost.

The heat resistance of the PTE film capacitance is utilized in aerospace and military technology. Metalized polyester film capacitors are used in situations where lengthy stability is required at a reasonable cost.

Ceramic Capacitor

Ceramic capacitors are capacitors that use ceramic as a dielectric material. Ceramics were one of the earliest materials used as an insulator in capacitor manufacture.

Ceramic capacitors come in a variety of designs, including ceramic tube capacitors and barrier layer capacitors, which have become obsolete due to their size, parasitic effects, or electrical properties. Multilayer ceramic capacitors (MLCC) and ceramic disc capacitors are the two most prevalent forms of ceramic capacitors.

Surface mounted (SMD) technology is used to make multilayer ceramic capacitors, and because they are lower in size, they are commonly used. Ceramic capacitors typically have values ranging from 1nF to 1F, with values up to 100F being feasible.

Ceramic disc capacitors are formed by coating a ceramic disc with silver contacts on both sides, and these devices are constructed up of many layers to achieve a higher capacitance. Due to parasitic effects like as resistance and inductance, ceramic capacitors will produce high-frequency responses.

Conclusion

We discussed the many types of capacitors and their applications in this article. We hope that by reading this page, you have gotten a fundamental understanding of capacitor kinds. Please feel free to leave a remark in the box below if you have any questions concerning this article or its implementation. Also, if you need to know more information about types of capacitors, visit this link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is Ceramic Capacitor: compact in size with great charge storage

- What is a Non-Polarized Capacitor? Types & Function

- What is a Polarized Capacitor

- What is an Electrolytic Capacitor: an introduction to features, construction, and uses

- What is Mica Capacitor: the name suggests many uses

- Differences Between P-Type and N-Type Semiconductors

- What are the Different Types of Actuators?

- Types of Electric Circuits: All Classification with Application

- How does a Circuit Breaker Work?

- What is Resistive Circuit

- What is Linear Circuit

- What is RL Circuit

- What is RC Circuit?

- What is RLC Circuit

- What is Capacitive Circuit?

- Types of Resistor: Classification, Application, and Finally Clarification

- What is Parallel Circuit? Definition & Example

- What is Series Circuit? Definition & Example

- What is a Closed Circuit? Definition & Example

- What is a Short Circuit? A Clear Definition & Protection Guide

- Difference Between Linear and Nonlinear Circuits

- What are the Differences Between Series and Parallel Circuits?

- The 8 Best Circuit Breaker Locators in 2022