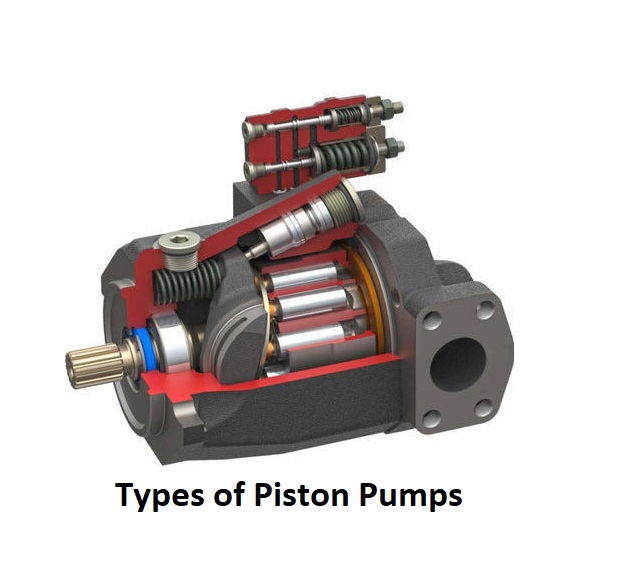

Types of Piston Pumps – Pumps have become an indispensable component of all domestic and industrial applications. The piston pump is one of many distinct types of pumps available on the market. A piston is used in piston pumps to compress the fluid. This post focuses on several types of piston pumps.

The piston pump, as well as basic devices, are powerful. A chamber, a piston, plus a few control devices make up these pumps. These pumps work by allowing media to flow downward into the chamber, lowering the number of media in a hand pump. The decreased media can be pushed throughout the open exit valve when the air pressure exceeds the opening valve spring. As the piston returns to its original position, it opens the intake valve and closes the exit valve, allowing suction to be employed to pull in the additional medium for compression. This post provides an overview of piston pumps, including how they function, what types they come in, and so on.

⇒ View a Comprehensive List of Piston Pumps for Sale and Their Suppliers ⇐

What is a Piston Pump?

A positive displacement (PD) pump can be characterized as a piston pump. For moving liquids, these pumps employ a piston, diaphragm, or plunger. The input and output valves on these pumps are check valves. The universal piston pump is a rotary pump that operates the piston via a wheel or rotating shaft. From its center, the revolving component can be attached to a shaft, which can then be connected to the piston. When the revolving component turns, it pulls the shaft and piston down with it.

Piston Pump Working

The piston pump works in the same way that PD pumps do. Because they raise the volume of the liquid with the assistance of the pumping mechanism force. These pumps may run on electricity from a power source.

These pumps have many pistons as well as a series of control devices. Two pistons and two control devices are included in the duplex pump. A triplex pump, on the other hand, has three pistons and three control devices. It is critical to inspect the regulating devices on both sides to confirm that the liquid flow direction is flowing on both sides.

These pumps are single-acting rather than double-acting. On each end of a double-acting pump, there are two sets of regulating devices and fluids. This allows the pump to finish a pumping cycle by flowing in the opposite direction. When the piston is moving in one direction, it will exhaust in the other. For completing a cycle, this pump requires solo action versions that flow in both directions.

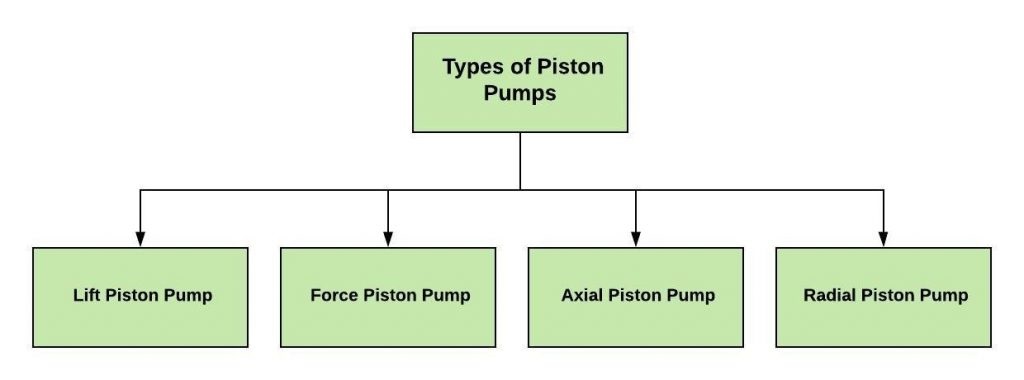

Different Types of Piston Pumps

There are four different types of piston pumps: lift pumps, force pumps, axial pumps, and radial piston pumps. Lift and force pumps can be operated manually or with the assistance of an engine from these pumps.

Lift Piston Pump

The piston can draw fluid into the lower section of the cylinder with the assistance of a control mechanism called a valve in this sort of pump. Fluid flows into the higher area of the cylinder through control mechanisms positioned in the piston on the below stroke. The fluid can then be expelled from the higher area of the cylinder through a spout on the upstroke.

This form of piston pump draws the fluid from the suction valve to the cylinder’s bottom part. The piston rises upward during the upward stroke, causing suction. The fluid enters the cylinder through the valve as a result of this.

The piston now slides downward during the downward stroke, putting pressure on the fluid. In the piston, some valves allow the fluid to pass through to the opposite side. The fluid in the top portion of the cylinder is driven out during the upward stroke, while the fluid in the bottom half of the cylinder is sucked in. As a result, it takes three piston strokes to draw and distribute the fluid. The lift piston pump operates in this manner.

Force Piston Pump

The piston pump’s upstroke might pull fluid through an intake valve to the cylinder in this sort of pump (tube). The fluid level can be emptied into the output tube by an exit valve at the end of the downstroke. The force pump works similarly to the lift pump. The upward motion of the piston in this pump draws fluid into the cylinder through an inlet valve. The downstroke expels the fluid from the pump into the discharge pipe through an output valve after the compression operation.

The major distinction between a forced pump and a lift pump is that a lift pump requires an additional upstroke to release the fluid, whereas a force pump does not.

To suction the fluid, the force pumps require only one upward stroke and one downward stroke. To fill the power pump with water, all it takes is one upstroke and one downstroke. The fluid is discharged by the lift pumps on the second upstroke, while the fluid is discharged by the force pumps on the first downstroke. A sort of force piston pump is the well-known “hand pump.”

Axial Piston Pump

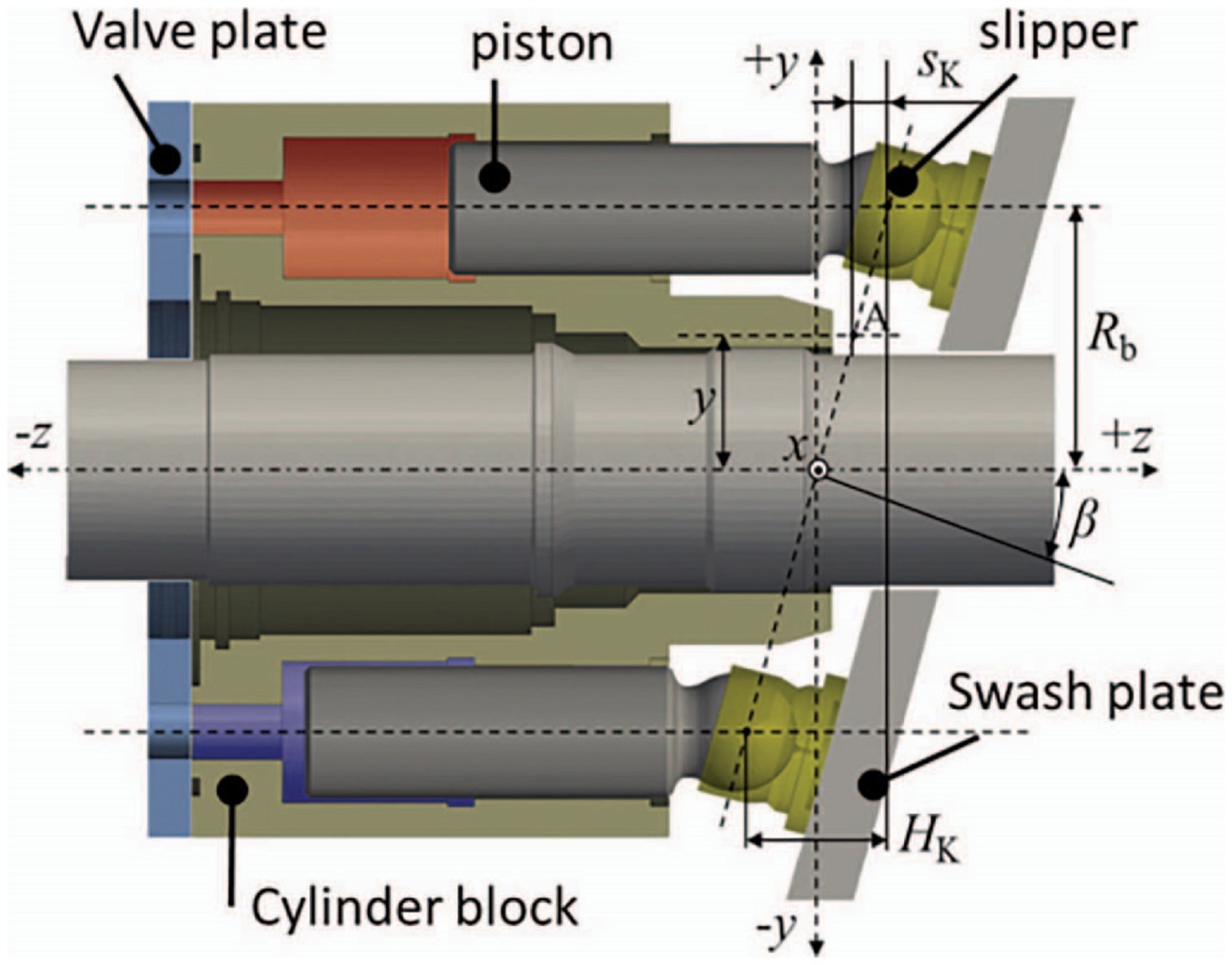

This is a positive displacement (PD) pump with many pistons arranged in a circular array within a tube block. With an essential shaft connected to the pumping pistons, this block may be operated to spin its symmetry axis. These pumps can be used as a compressor for an automobile, as a standalone pump, or as a hydraulic motor.

The pistons of this pump are arranged in a row parallel to the driving crankshaft. Axial pumps can be used for both constant and variable displacement applications. The cylinder and pistons alternate around the central vertical axis of these pumps. As they move on a fixed swash plate with a changeable angle, the shoe and pistons reciprocate inward and outward in the cylinder.

The piston switches between suction and discharge valves as it rotates. The liquid is injected into the piston chamber when the piston passes through the suction valve. It drains liquid from the piston chamber when it passes past the discharge valve.

The piston’s rotation speed is controlled by the crankshaft’s mechanical rotation input. The swash block angle controls the quantity of liquid sucked into the compression cylinder during piston motion. Axial piston pumps are further divided into the following categories:

- Straight axis piston pump

- Bent axis piston pump

Bent Axis Piston Pump

The pistons of this pump are angled to the driving shaft and Thrust Plate. A universal connection, not visible, connects the piston block shaft to the driving shaft. All of the components of the driveshaft, thrust plate, piston block shaft, and piston block rotate. Unlike a swash plate pump, where the piston rods glide past a stationary swash plate, the connecting rods are linked to the thrust plate and rotate with it.

The outlet ports are semi-circular holes in the Valve Plate, which can be seen on the edge on the far right of the system and in a head-on view below, right. Half of the pistons suck in fluid as they pass over the intake port while the pump rotates. The fluid from the other pistons is discharged through the output port. The radial piston pump, swash plate pump, and wobbling pump should all be compared to this pump.

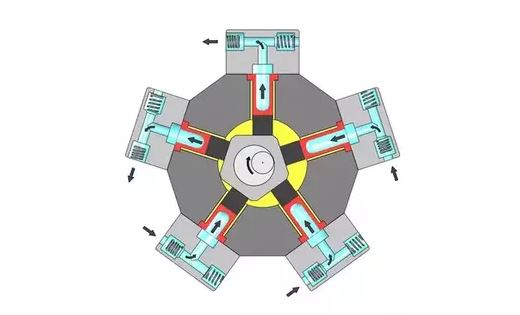

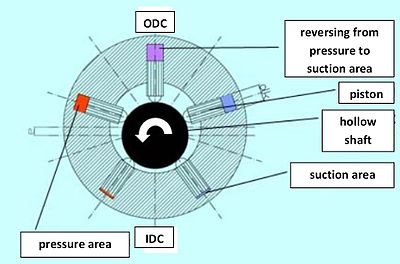

Radial Piston Pump

This pump is a type of hydraulic pump in which the working pistons expand in a radial track symmetrically in the vicinity of the driving shaft, in contrast to the axial piston pump’s direction of expansion. Some pistons are housed in a cylindrical block that surrounds the rotor hub in radial piston pumps. A shaft, a piston, and a rotor make up the cylinder. The fluid is moved in and out of the cylinder by the pintle.

The pump housing is eccentrically linked to the rotor. Hydraulic oil is taken into the cylinder cavity and drained from the cylinder cavity as the piston moves in and out of the cylinder. The valve on the middle shaft houses the pump’s input and outflow. When a piston expands, it connects to the inlet, and when it shrinks, it connects to the outlet.

Radial piston pumps are used in high-pressure applications (working pressures ranging from 400 to over 700 bar), such as presses, plastics processing machines, and machine tools for sustaining oil pressure. They provide a variety of benefits, including high efficiency, high-pressure capacity up to 1,000 bar (14,000 psi), low flow and pressure fluctuations, minimal noise development, extremely high load at low speed, excellent dependability, and more.

Because of its huge radial dimensions, it is more significant than an axial pump and so is not always available in situations with restricted space.

Piston Pump Selection

The rate of flow, volume stroke, head of the pump, outlet diameter, pressure, horsepower, power rating, and ultimately operating temperature are the most important factors to consider while selecting these pumps.

Materials Used for Different Types of Piston Pumps

The materials used to construct a piston pump are mostly determined by the pump’s intended usage. The casing and cylinder materials must be strong enough to withstand the operational environment conditions. Materials that come into contact with the pumped medium must be resistant to corrosion caused by the liquid. The materials utilized in this pump are mentioned further down:

Cast iron has tensile strength, toughness, and scratch resistance that are comparable to high force ratings.

Plastic materials are inexpensive and have a high resistance to corrosion and chemical assault.

Stainless steel alloys and steel are resistant to corrosion and chemicals, and they have higher tensile strengths than plastics, resulting in higher pressure ratings.

Aluminum, bronze, brass, porcelain, and nickel-alloy are among the other materials employed in the pump’s design.

Advantages

The following are the key benefits of a piston pump:

- Force may be controlled without affecting the flow rate.

- The pressure range is rather broad.

- With good control device design, skilled in moving heavy fluids, slurries, and abrasives.

- Changes in flow rate and pressure have a minor impact on the act.

Disadvantages

The following are the primary drawbacks of a piston pump:

- The cost of maintenance and operation is generally high, and the equipment is big and heavy.

- They can only tolerate lower flow rates.

- The flow is pulsing.

Applications of Piston Pumps

- Piston pumps are used to manage extremely low flow rates at high pressure.

- These pumps are used to convey fluids with a high viscosity.

- They used to be in charge of pumping hydraulic oil.

- High-pressure cleaning is also done using the piston pump.

- Pumps like this are used in industrial processing equipment.

This concludes Linquip’s discussion of piston pumps, which are similar to hydraulic pumps in that they are used to power both large and small devices. Paint, pastry, chocolate, and other materials are commonly transferred using piston pumps. The size of these pipes has grown to be used in industries. In modern industrial applications, which incorporate several pistons grouped within a circular cylinder block, all forms of piston-pumps, both radial and axial, are utilized.

As a result, the fundamental schematic, operating principle, and categorization of piston pumps have been presented. These are the hydraulic pumps that are thought to be the most efficient. These are some of the most popular hydraulic pumps because of their durability and low maintenance requirements. They have the benefits of axial and radial flow, as well as a large pressure range. It is simple to control flow since it is independent of head pressure and rate of flow.

If you have any additional questions, please contact Linquip Piston Pump Experts for assistance. Some of the main FAQs about different types of piston pumps are listed below.

FAQs about Different Types of Piston Pumps

What does piston mean?

It consists of a disc or cylindrical structure that is inserted into a tube or metal cylinder. Based on the flow of liquid or compressed gas, the piston may be pushed up and down.

What is a hydraulic piston pump?

A hydraulic piston pump uses compressed gas as its operating fuel. Because of its adaptability, it may be used in a variety of ways.

What are the main types of piston pumps?

Axial and radial flow are the two types of them. Lifted piston and force piston are two additional categories.

Does a piston stop moving?

No, under normal operating conditions, the piston of an engine or a pump never stops moving. It rises and falls in response to the movement of a liquid or compressed gas.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Piston Pump & How Does it Works?

- A Cheat Sheet For The Types of Pump Couplings

- Types of Fire Hydrant Systems

- Different Types of Pumps: Ultimate Guide

- Types of Centrifugal Pumps: All Classification & Working Principles

- 3 Types of Well Pumps + Applications

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- What is Dynamic Pump & How Does it Works?

- A Cheat Sheet For The Types of Pump Couplings

- Different Types of Pumps: Ultimate Guide

- Different Types of Hydraulic Pumps: a Complete Guide

- Types of vane pumps: review the types, select the best

- 5 Types of Vacuum Pump and Applications + PDF

- Types of Water Pumps and Their Principles

- 3 Types of Oil Pumps + Working Principle & PDF

- 5 Main Types of Fuel Pump & How They Works?

- What is Deep Well Pump & How Does it Works?

- 3 Types of Positive Displacement Pump + Name & PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Types of Screw Pumps: How Each Type Gives Benefits?

- What is Head of a Pump? A Complete Guide

- The 5 Best Air Source Heat pump in 2022 (Clear Guide)

- 7 Best RV Water Pump (Clear Guide & Review)

- The 10 Best Electric Air Pump (Clear Guide)

- The Best HVAC Vacuum Pump (Clear Guide)

- The 5 Best Well Pump (Clear Guide)

- The 10 Best Condensate Pumps: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 7 Parts of Screw Pump: Advantages and Disadvantages

- 12 Types of Water Pressure Pumps with Applications & Characteristics