Vane pumps are a form of positive displacement pump and are extensively utilized in autos, power steering systems, and air conditioners. They are capable of managing intermediate viscosity fluids and excel at handling low viscous fluids. These pumps are also employed in the conversion of high-pressure gas to a low-pressure gas. In this latest blog post at Linquip, we are going to talk about different types of vane pumps. So, read the blog below.

⇒ View a Comprehensive List of Vane Pumps for Sale and Their Suppliers ⇐

How Many Types of Vane Pumps are There?

There are mainly three types of vane pumps:

- Unbalanced Vane Pumps

- Balanced Vane Pumps

- Variable Displacement Vane Pumps

As mentioned earlier, vane pumps are positive displacement pumps that use vanes mounted to a rotor to increase the pressure of the flowing fluid. The vanes of the vane pumps can be variable in length or tensioned to maintain contact between the vanes and the pump wall as the vanes revolve. There are mainly three types of vane pumps, each type has its own set of benefits.

Understanding the unique characteristics of unbalanced, balanced, and variable displacement vane pumps allows for the selection of the most appropriate vane pump solutions to meet specific operational requirements, ensuring optimal performance and efficiency in various applications.

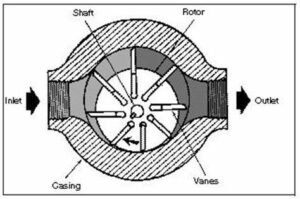

1. Unbalanced Vane Pumps:

Unbalanced vane pumps are made up of a cylindrical rotor that is offset inside a circular housing. It signifies that the centers of the cylindrical rotor and the shell do not coincide. The casing’s center and the rotor’s center are some distance apart. No leakage exists between the housing and the vane tip. Due to pressure variations between the intake and exhaust ports, a side thrust is formed on the rotor shaft. The bearing life is reduced due to the lateral force on the shaft. These types of vane pumps are known as an “imbalanced vane pumps” because of pressure fluctuations between the input and exhaust ports. There is no side force on the rotor shaft in a balanced vane pump.

2. Balanced Vane Pumps:

The balanced rotary vane pump has an elliptical casing. The elliptical casing and rotor have the same center. There isn’t any offset. These types of vane pumps are designed to be adaptable and are commonly used in mobile and industrial applications. Because these pumps have two inlets and an outlet, there is no pressure differential between the inlets and outputs. The two entrance ports are on opposing sides of the machine. Similarly, the outlet ports are on opposing sides as well. The intake and outlet port assembly balance equal and opposing thrust forces so that the rotor shaft is not subjected to lateral thrust forces. This balancing pump provides superior performance and long service life in a variety of applications. Balance vane pumps have a service life of more than 24,000 hours in industrial applications. The size of the cavity between two vanes decreases from intake to exit. The pump draws fluid in through the intake port and discharges it through the output port. The rotor is under high pressure in the exit area, and the forces in the two outlet zones are equal but opposing. As a result, there is no net load on the shaft’s bearings.

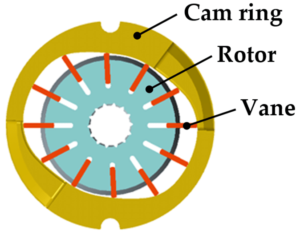

3. Variable Displacement Vane Pumps:

Variable displacement vane pumps allow you to alter the size of the pocket; the delivery rate changes as a result of the varied sizes of the pump pocket. The vanes on these types of vane pumps do not come into direct contact with the pump housing. A ring separates the vane from the casing in this rotary vane pump. The response ring is the name given to this ring. One end of this ring is attached to the spring, while the other end is attached to the adjusting screw. The adjustment screws modify the size of the pump pocket. As the adjustment screw begins to rotate, the response ring travels up and down. The offset between the rotor center and the response ring center changes as the reaction ring swings up and down. As the offset varies, the size of the pocket changes, affecting the pump’s delivery flow rate.

Summary

A vane pump is a form of positive displacement rotary pump. It is referred to as a “vane pump” because the impact of the vanes pressurizes the fluid. Vane pumps are not designed to handle very viscous fluids. Vane pumps are good for pumping low to medium viscosity liquids, and those containing entrained gases, and may produce a smooth, low-pulsation output. There are three types of vane pumps available including unbalanced vane pumps, balanced vane pumps and variable displacement vane pumps. Unbalanced vane pumps are a sort of vane pumps that are common. Because of the pressure differential between the input and exit valves, they are known as an unbalanced vane pump. Balanced vane pumps, on the other hand, provide greater service and last longer. However, you might have more question about these pumps. Please leave your comments about the types of vane pumps by registering at Linquip. Also if you have any questions, ask our experts.

Watch Video about Types of Vane Pump

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Vane Pump & How Does it Works?

- A Cheat Sheet For The Types of Pump Couplings

- Different Types of Pumps: Ultimate Guide in 2022

- Different Types of Hydraulic Pumps: a Complete Guide

- Types of Piston Pumps

- Types of Dynamic Pumps

- Types of Fuel Pump

- 5 Types of Vacuum Pump and Applications + PDF

- Types of Water Pumps and Their Principles

- 3 Types of Well Pumps + Applications

- 3 Types of Oil Pumps + Working Principle & PDF

- What is Deep Well Pump & How Does it Works?

- 3 Types of Positive Displacement Pump + Name & PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Types of Screw Pumps: How Each Type Gives Benefits?

- What is Head of a Pump? A Complete Guide

- The 5 Best Air Source Heat pump in 2022 (Clear Guide)

- 7 Best RV Water Pump In 2022 (Clear Guide & Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Types of Centrifugal Pumps: All Classification & Working Principles