Repulsion Motor is a special kind of single-phase AC motor which works via the repulsion of similar poles. In the past, these motors were used as traction motors in electric trains; however, they have been outdated by recent types of electric motors.

A single-phase commutator-type motor with a wound rotor and brush configuration is known as a repulsion motor. It is based on the magnetic repulsion between two poles. The use of a Repulsion Motor is essential while using Industrial Tools. Repulsion Motors are available from a variety of Suppliers And Companies, as well as various manufacturers and distributors, and there are several repulsion motors for sale on Linquip.

There is a complete selection of repulsion motor services on the Linquip platform that meets all of your needs. Linquip can connect you with a number of Repulsion Motor service suppliers and experts who can help you. Linquip can connect you with Repulsion Motor Specialists and subject matter experts who can help you test your equipment.

This article discusses an overview of the repulsion motor, its different types, applications, and how its principle helps to rotate a motor. Read this new blog in Linquip to find out more about this motor.

What is a Repulsion Motor?

A repulsion motor is a single-phase electric motor that operates by providing input AC. The main application of repulsion motor is electric trains. It starts as a repulsion motor and runs as an induction motor, where the starting torque should be high for a repulsion motor and very good running characteristics for an induction motor. In repulsion motor direction of rotation of the motor is the same as that of brush shift.

Construction of repulsion motor

The repulsion motor is equipped with the stator, rotor, and commutator brush assembly. The stator carries a single-phase exciting winding similar to the main winding of a single-phase induction motor. The rotor has distributed DC winding connected to the commutator at one end just like in the DC motor. The carbon brushes are short-circuited on themselves and find a use for conducting current using the armature.

Working principle of repulsion motor:

The basic principle behind the working of repulsion motor is that “similar poles repel each other.” This means two North poles will repel each other. Similarly, two South poles will repel each other. When the repulsion motor winding is supplied with single-phase AC, it produces a magnetic flux along the direct axis. WhenT this magnetic flux links with the rotor winding, it creates an EMF. Due to this EMF, a rotor current is produced. This rotor current in turn produces a magnetic flux that is directed along the brush axis due to commutator assembly. Due to the interaction of stator and rotor produced fluxes, an electromagnetic torque is produced.

Types of repulsion motors

There are three types of repulsion motor they are

- Compensated repulsion motor

- Repulsion-start induction motor

- Repulsion induction motor

They differ in construction, operating characteristics, and industrial applications. These three kinds of repulsion motor are available in the market which works under the principle of repulsion like the following.

-

Compensated repulsion motor

It is provided with an additional winding, called the compensating winding, to improve power factor and provide better speed regulation. This winding is much smaller than the stator winding and is usually wound in the inner slots of each main pole and is connected in series with a rotor through an additional set of brushes placed midway between the usual short-circuited brushes. A compensated type motor finds use where there is a need for high power at the same speed.

-

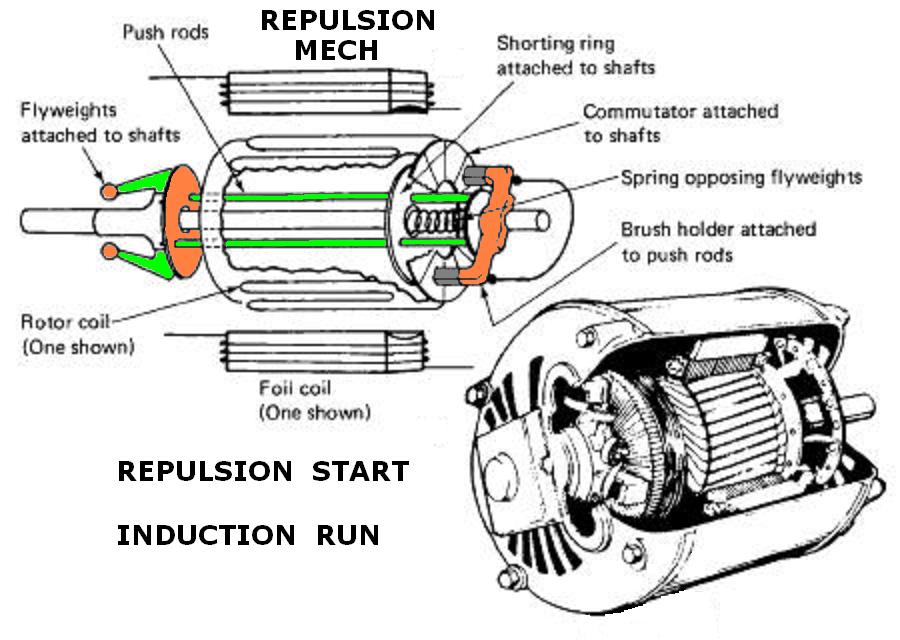

Repulsion start induction motor

As the name implies the repulsion-start induction motor starts as a repulsion motor and runs as an induction motor. The general construction of this motor is quite similar to a repulsion motor. The only difference is that in addition to the basic repulsion motor construction it is equipped with a centrifugal device which operates at about 75-80 percent of synchronous speed and short circuits all of the commutator segments. The repulsion start induction motor combines the desirable starting characteristics of the repulsion motor with the operating characteristic of the induction motor.

Such motors are suitable for commercial refrigerators, compressors, pumps, hoists, and other constant speed drives, particularly those which have high inertia and a prolonged starting period. The usual rating is from 1/3 kW to 12 kW but for special applications, ratings as high as 30 kW are available. Although this kind of repulsion motor price is high, this device does save wear and tear on brushes and runs quietly.

-

Repulsion induction motor

According to the characteristics of the repulsion induction motor, it has a single-phase stator winding, as a repulsion-start induction motor has, but it has two separate and independent windings on the rotor in common slots. The inner winding is a squirrel cage winding with rotor bars permanently short-circuited, while the outer winding is a repulsion or commutator winding similar to a dc armature winding.

When the motor starts, the squirrel cage winding, due to its high reactance, does not affect and the motor starts as a repulsion motor. Such a motor finds a use for applications requiring a high starting torque with essentially a constant running speed. The common ratings are 1/6 to 4 kW. Common applications are household refrigerators, garage air pumps, gasoline pumps, compressors, etc.

Repulsion Motor Applications

The applications of repulsion motors include the following.

- Applications of Farm Motors

- Film winding machines

- Hoists

- Machines in Textile

- Machines for floor maintenance

- Printing presses

- Air compressors

- Pumps & Fans

- Laundry equipment

- High-speed lifts

- Mixing machines

- Machine tools

- Air pump

- Mining tools

- Petrol pumps

- Drive compressors

What Is the Advantage of a Repulsion Motor?

Excellent beginning torque, low starting current, and a wide range of speed control with smooth speed fluctuation are all advantages of a repulsion motor. The following are some of the repulsion motor’s drawbacks. At lower speeds, the power factor is much lower. Brushes and commutators quickly exhaust owing to heat production and arcing at the brush assembly.

Thus, this is all about the repulsion motor. Most of the commutator motors are restricted to about 1500 V as high voltages provide rise to a threat of arcing across it. These motors find use where high voltages are required because the circuit of the rotor is not connected electrically to the power supply.

So, there you have a detailed description of this motor. If you enjoyed this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you through? Feel free to sign up on our website to get the most professional advice from our experts.

Dowmload Repulsion Motor PDF

Read More In Linquip

- 10 Types of CNC Machine + Applications & PDF

- 13 Parts of CNC Machine + Function & PDF: A Clear Guide

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- Working Principle Of DC Motor: 2022 Complete Guide

- Working Principle of Stepper Motor: 2022 Ultimate Guide

- Working Principle of AC Motor: 2022 Ultimate Guide

- Working Principle of Induction Motor: 2022 Full Guide

- DC Motor Efficiency: Calculation: Formula & Equation

- What is Gear Shaft? Clear Principle & Advantages

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- Series DC Motors: A Comprehensive Guide

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- What is a Hysteresis Motor: Ultimate Guide

I love this

Thanks for visiting our website and leaving your comment, Akwech! We hope to hear from you again in our other posts.