Aluminum is used in a variety of industries, including aircraft, construction, medical, general manufacturing, and transportation, because of its adaptability and desired qualities. Here, we will present some of the most leading aluminum tubing suppliers and manufacturers in the USA in 2026.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Aluminum Tubing, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Aluminum Tubing Suppliers and Companies, along with Aluminum Tubing Experts available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

Basics of Aluminum Tubing

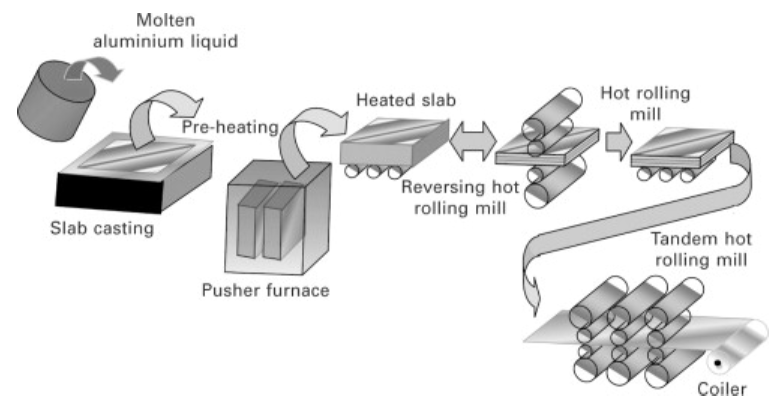

How Aluminum is Produced?

Two activities are carried out throughout the aluminum production process:

- Using the Bayer method, aluminum oxide is extracted from bauxite, a mineral that contains other metal compounds and aluminum oxide. The aluminum oxide is removed, allowed to crystallize, and then heated to create pure aluminum oxide.

- By immersing the substance in an electrolyte solution and using a direct current to start a chemical reaction that separates the aluminum atoms from the oxygen atoms, the Hall-Héroult method further refines crystalline aluminum oxide. The molten aluminum that is produced is 99.8% pure and may be formed into the desired shape for processing.

Although aluminum is a very strong material on its own, alloys are frequently added to it during the production process to increase its strength even further. Aluminum is renowned for its endurance and capacity to absorb energy during collisions, in addition to its strength. It also has a superior strength-to-weight ratio than steel, which enables the creation of robust yet lightweight components.

Utilization of Aluminum Tubing

Many well-known industries use aluminum for both standard and specialized uses, including:

- Automobiles and aerospace: Aluminum tubing is used by makers of fuel lines, hydraulic systems, and aircraft fuselages.

- Construction: A wide variety of construction projects use aluminum material, including creating curtain walls, door and window frames, roofing, and siding.

- Cooling and heating systems: Due to its strong thermal conductivity qualities, aluminum tubing is a crucial component of many HVAC and refrigeration systems.

- Marine: Because aluminum has stronger buoyancy and seawater corrosion resistance than other construction materials, it is utilized to build maritime equipment like shark cages.

- Medical: Medical apparatus and tools Aluminum tubes are frequently used by manufacturers to build items like bed frames, foldable stretchers, and wheelchair frames.

- Recreation: Recreational equipment producers use aluminum tubing to make items like camp chairs, tables, and tent poles.

Advantages of Aluminum Tube

Compared to other materials, aluminum offers producers and consumers several advantages, including:

- Lightweight but sturdy build: An outstanding strength-to-weight ratio is displayed by aluminum. Aluminum and its alloys may be as strong as steel while weighing only a third as much.

- Durability: Aluminum is resistant to various environmental elements, including UV radiation and corrosive chemicals. Aluminum items benefit from a longer lifespan because of this characteristic.

- Flexibility and simplicity of construction: Aluminum may be produced using many various manufacturing methods, such as rolling, extrusion, forging, casting, etc., for practically any purpose because it is available in a number of alloys with differing qualities.

- Non-combustible: At about 600 degrees Fahrenheit, aluminum begins to melt, but it does not burn or give out any potentially dangerous fumes.

- Electrical and thermal conductivity: Aluminum may be employed in electrical and thermal transfer applications because of its strong electrical and thermal conductivity qualities.

- Recyclability: Because aluminum is so easily recycled, businesses are able to use and recycle resources for construction projects.

An aluminum tube offers producers and end users numerous benefits, including a fantastic strength-to-weight ratio and great compression and support qualities. The square shape also aids in homogeneity throughout the tube and a more dependable end result. Generally speaking, square aluminum tubing is a more affordable option than steel. It is appropriate for a number of fabrication applications since it is offered in a wide range of sizes and dimensions.

Top Aluminum Tubing Suppliers and Manufacturers in the USA

Listed below are the Top Aluminum Tubing Suppliers and Manufacturers in the USA, ranked by company size. Each company’s information includes its headquarters, sales, year of foundation, and the number of employees, and annual sales. US million dollars are used to measure annual sales. Following the table are summaries of each company.

| Company name | Headquarters | Year founded | No. of Employees | Annual sale |

|---|---|---|---|---|

| Kaiser Aluminum | Franklin, Tennessee | 1946 | 1000+ | $250 Mil. and over |

| Aluminum Shapes LLC | Delair, Pennsauken Township, New Jersey | 1955 | 200-499 | $100 - 249.9 Mil |

| Yarde Metals, Inc. | Southington, Connecticut | 1976 | 500-999 | $100 - 249.9 Mil |

| Brazeway | Adrian, Michigan | 1946 | 50-99 | $50 - 99.9 Mil |

| Peerless of America | Effingham, Illinois | 1912 | 100-199 | $50 - 99.9 Mil |

| Arrow Fabricated Tubing | Garland, Texas | 1978 | 500-499 | $50 - 99.9 Mil |

| Altec | Birmingham, Alabama | 1947 | 200-499 | $25 - 49.9 Mil |

| Testrite Instrument Company, Inc. | Hackensack, New Jersey | 1919 | 100-199 | $10 - 24.9 Mil |

| Universal Tube, Inc. | Rochester Hills, Michigan | 1980 | 200-499 | $25 - 49.9 Mil |

| Iowa Aluminum, Inc. | Albia, Lowa | 1999 | 10-49 | $10 - 24.9 Mil |

| Ryerson Inc. | Elk Grove Village, Illinois | 1842 | 5,000+ | $1 Billion |

| Valley City Metal Products, Inc. | Valley City, Ohio | 1972 | 200 | $1 Billion |

Kaiser Aluminum

Kaiser Aluminum, with its corporate headquarters in Franklin, Tennessee, is a top producer of seamless, structural extruded, and drew aluminum tubes. The aerospace, packaging, and automotive sectors are served by the business.

Aluminum Shapes LLC

Aluminum Shapes LLC, based in Delair, New Jersey, has more than 60 years of expertise in designing and producing aluminum goods, including the extruded tube. The consumer goods, building, construction, transportation, electrical, and automotive industries are all served by the manufacturer.

Yarde Metals, Inc.

For the automotive, aerospace, and oil and gas industries, Yarde Metals, Inc. is a distributor of drawn, extruded, and seamless aluminum tubing. Round, square, and rectangular tubes are all readily available.

Brazeway

Brazeway, a renowned producer of extruded aluminum round tubes for the appliance, HVAC, refrigeration, and automotive sectors, was established in 1946. Extruded aluminum tubes are appropriate for applications involving heat transmission, fluid transport, energy, and battery cooling.

Peerless of America

Extruded aluminum tubing is produced by Peerless of America for use in a variety of sectors, including chilled retail displays, military vehicles, aerospace, automotive, air conditioning, power, energy, and medical refrigeration. The firm manufactures custom-formed tubing and tube assemblies.

Arrow Fabricated Tubing

Aluminum tubing products made by Arrow Fabricated Tubing in Garland, Texas, include return bends, crossovers, interconnected tubing, and brazed assemblies. The HVAC sector is served by the ISO-certified business.

Altec

Altec is a custom aluminum extruded tubing manufacturer with an ISO certification. The fabricator services the windows, doors, architectural, energy, recreational, and transportation industries with tubes up to 56 feet in length.

Testrite Instrument Company, Inc.

Telescopic aluminum round, square, and oval tubing is a specialty of Testrite Instrument Company, Inc. Additionally produced are shock cord and non-locking round tubing.

Universal Tube, Inc.

Aluminum tubes are made by Universal Tube, Inc., a company that was founded in 1980 for use in the HVAC, automotive, refrigeration, and other industries. The company manufactures transmission tubes as well as vent or brake, powertrain, steering, fuel, and safety systems.

Iowa Aluminum, Inc.

Iowa Aluminum, Inc., a company based in the Midwest, specializes in fabricating and customizing aluminum extruded shapes, including square tubing. The fabricator provides services to the transportation, electrical, marine, automotive, sports goods, and construction sectors.

Ryerson Inc.

Ryerson Inc. is a major player in the North American metal distribution industry, with a rich history dating back to 1842. They are a distributor and processor of various metals, including aluminum tubing, stainless steel, and carbon steel. Ryerson Inc. has a large footprint across North America with over 100 locations strategically positioned to serve its customers. They offer a wide variety of services beyond just distribution, including processing, fabrication, and logistical support. This makes Ryerson Inc. a one-stop shop for many metalworking needs.

Valley City Metal Products, Inc.

I apologize, but the information I provided earlier regarding Valley City Metal Products, Inc. was inaccurate. They are not a major manufacturer of aluminum tubing. Based on my current search, Valley City Metal Products, Inc. located in Shelby, Michigan, specializes in custom metal fabrication. Their capabilities include CNC machining, fabrication, milling, laser cutting, turning, and stamping. They work with a variety of materials including stainless steel, low or medium carbon steel, aluminum, brass, and galvanized steel. They offer services from prototype to production volume runs and cater to various industries including automotive, agricultural, and construction.

Download Top Aluminum Tubing Suppliers and Manufacturers in the USA (2025) PDF

Read More on Linquip

- Aluminum Suppliers in USA and Worldwide

- Top Castings Suppliers and Manufacturers in the USA

- Top 10 Stainless Steel Manufacturers Worldwide

- Top 15 Stainless Steel Suppliers in USA

- Top Dosing Pump Manufacturers and Suppliers

- Top Bearing Suppliers in USA & Worldwide

- The top 18 Metal Suppliers in USA and Worldwide

- Top 10 Diesel Fuel Supplier & Manufacturers (Ultimate Guide)

- Top 20 Suppliers of Tungsten and Tungsten Carbide

- Top 10 Railroad Equipment Suppliers in USA & Worldwide (Ultimate Guide)

- USA Metal Supplier & Manufacturers

- Top Metal Suppliers & Companies in World

- Top 15 Steel Companies & Suppliers in USA & Worldwide

- Top USA and International Steel Manufacturers: A Clear Guide

- Top wet wipes manufacturers in USA