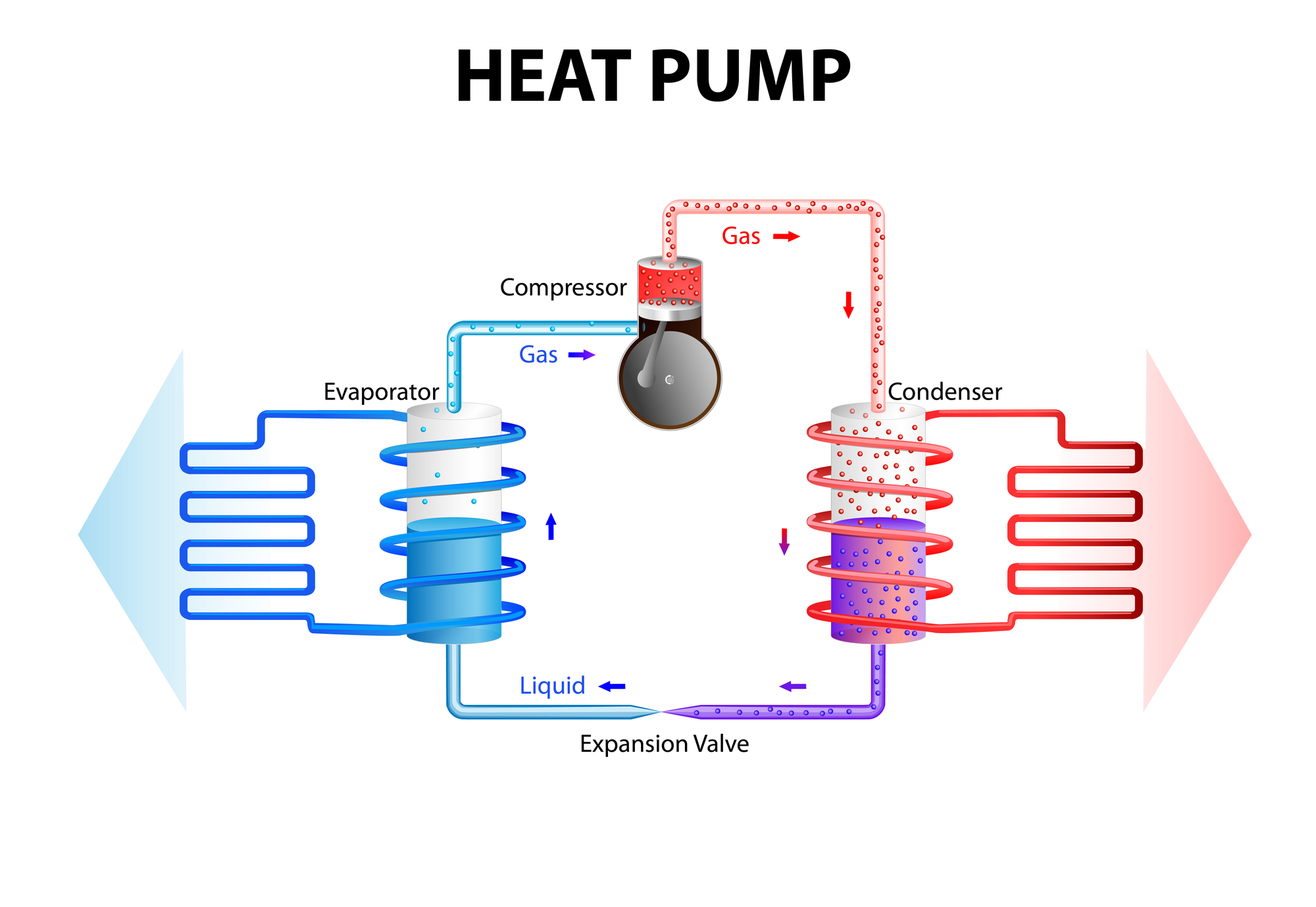

The parts of heat pump are similar to those of a refrigerator or an air conditioner, though they function in reverse. This is why heat pumps are sometimes called reverse refrigerators. The heat pump consists of four major components: a compressor, a condenser, an expansion valve, and an evaporator. When it comes to refrigerators and air conditioners, the evaporator is responsible for cooling or freezing, but for heat pumps, the condenser is responsible for heating the room.

There are a number of reasons why Linquip is the best place for you to learn about heat pumps and where to find all possible information. You may contact us with any questions you may have regarding heat pumps, and our experts will be ready to assist you. In order to gain a better understanding of heat pumps and the parts associated with them, you might want to take a look at Linquip’s article, “What is a Heat Pump and How does it Work?“.

Have you ever worked with heat pumps? Here at Linquip, you’ll find a comprehensive selection of Heat Pumps Products that will make it easy to discover and purchase what you’re looking for. Are you looking for a specific type of heat pump? It is Linquip’s pleasure to let you have free access to all available Heat Pump for Sale that are available on this website. The Linquip free quote/inquiry service gives you an opportunity to ask for a free quote or inquiry to receive heat pump prices from all Heat Pumps Suppliers and Companies.

This article will provide you with comprehensive knowledge about heat pumps and the key components of a heat pump.

⇒ View a Comprehensive List of Heat Pumps for Sale and Their Suppliers ⇐

How We Write This Blog Post about Parts of Heat Pump and Functions

When writing a blog post about Parts of Heat Pump and Functions, we start by researching the topic and consulting with experts in the field. We gather information from multiple sources, including web pages, articles, and books. We also draw on our own experiences and knowledge about heat pumps to provide a clear and comprehensive guide to the various parts and functions of a heat pump.

Our team at Linquip is dedicated to providing accurate and up-to-date information about heat pumps. We work closely with experts in the field to ensure that our blog posts are informative and helpful to our readers. If you have any questions about heat pumps or their parts and functions, feel free to contact us for more information.

A Brief Introduction

As society becomes more concerned about ecological and environmental issues, it is becoming more important to utilize heat and energy in more efficient ways. By using technology such as year-round space heating, the heat pump industry is able to re-distribute heat energy to a more practical location and purpose. As a result, localized or redirected heat can be applied while exchanging cool with heated air.

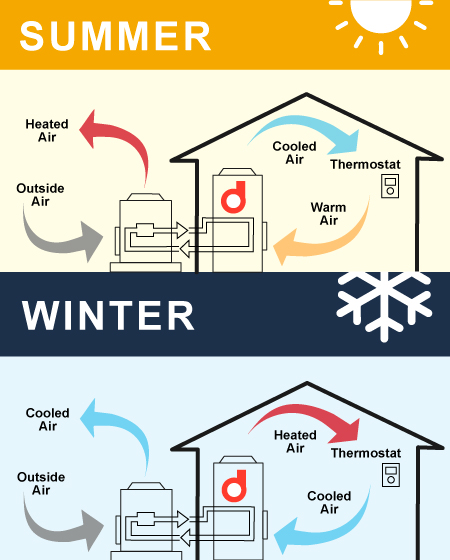

Heat pumps operate on the opposite principle from an air conditioning unit in terms of technological and thermodynamics. As an added benefit, most heat pumps provide cooling in the summer as well as heating in the winter. Reversing the flow of working fluid through coils allows this to be done. Essentially, the heat pump works by pumping liquids and/or gasses through an assembly, where they change phases as a result of varying pressure. The heat pump system is relatively expensive to set up. However, it provides an efficient and economical way to control temperatures and recover existing energy.

There is a current trend toward heat pumps, and they are even subsidized by plenty of state programs, which is logical because, aside from running on non-emission electricity, they are also relatively affordable and are powered by the national grid. Heat pumps, in general, are more efficient to operate when powered by centrally generated electricity than with local sources of heat, such as oil or gas although decentralized alternatives, such as solar panels, are also viable.

Types of Heat Pump

Heat pumps are typically classified as air-air, air-water, and water-water (brine).

Air-to-Air Heat Pump

Heat pumps are classified according to what is utilized at the evaporator and condenser, so in an air to the air heat pump, the surrounding air is cooled by the evaporator, and the cooled air is passed to the air of the room via the heat pump cycle. Generally, split air conditioners with a cycle-reverse feature follow this principle.

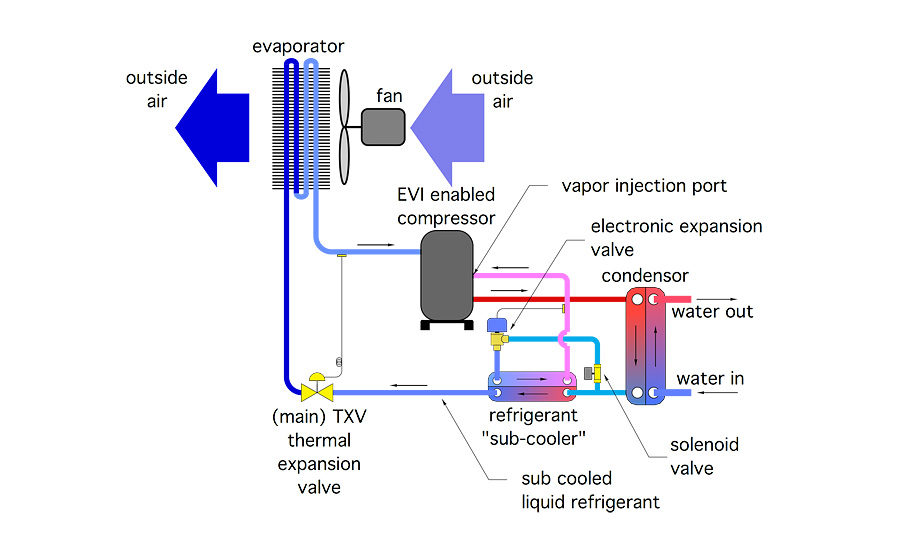

Air-to-Water Heat Pump

Air-to-water heat pumps pull heat from the surrounding air as with air-to-air systems, but on the secondary side, they release it into the hot water or heating circuit.

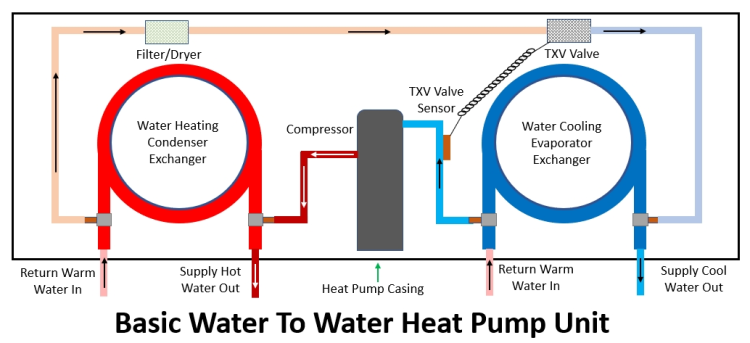

Water-to-Water Heat Pump

Heat is generally pumped from the ground to the hot water network in water (brine) to water heat pump. The choice depends on the planned temperature. It is important to consider possible operating conditions when using pure water during winter time and at subzero temperatures. You might add antifreeze (such as glycol) if you’re in doubt. A brine solution is preferred when the primary circuit operates at subzero temperatures.

Groundwater or well-water heat pumps and horizontal or vertical collector pumps are also subcategories of water (brine) to water heat pumps.

Groundwater or well-water heat pumps take their heat from groundwater or wells.

Houses with large yards are good candidates for water-to-water heat pumps with horizontal collectors. A reasonable depth is chosen for the placement of the collectors (plastic or copper pipes).

In the third variant of water-to-water heat pumps, the collector is vertical. No large area of land is needed for this, but deep drilling is required, which poses a considerable cost factor and must be reconciled with the geological situation.

A general rule does not apply in this case. A rocky ground, for instance, may be more conducive to drilling than clay soil. All heat pumps adhere to the following rule: Increasing the temperature in the heat source leads to a higher temperature in the evaporator, thereby increasing the efficiency of the system.

Various Parts of Heat Pump

16 Heat Pump Components include:

- Compressor

- Condenser

- Expansion Valve

- Evaporator

- Refrigerant

- Accumulator

- Compressor Contactor

- Crankcase heater

- ECM

- Reversing valve

- Thermostatic Expansion Valve (TXV)

- Thermostats

- Defrost system

- Fan

- Motors

- Refrigeration Coils

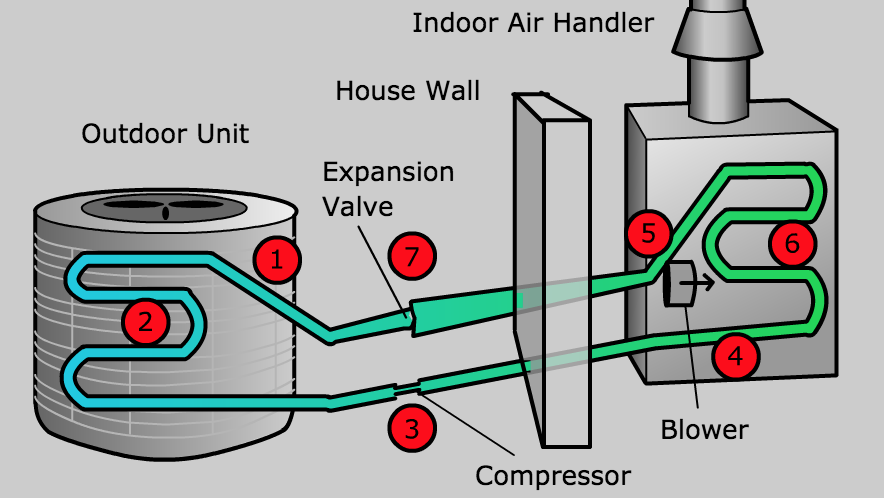

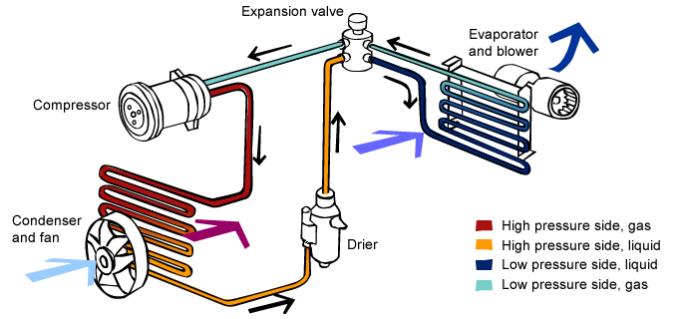

In order to better understand how your heat pump system works, it helps to understand what each part of the system does. An installation of a heat pump typically consists of two parts; an indoor unit, which is usually a furnace or air handler, and an outdoor unit, which contains the compressor and evaporator coils. As part of the heating process, the evaporator is located outdoors to extract heat from the surrounding air, while as part of the cooling process, the evaporator is installed indoors, where the condenser coil extracts heat from. A heat pump consists of the following components:

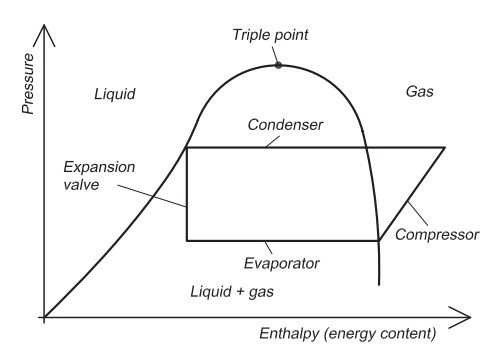

Compressor

An important component of a heat pump is the compressor. The refrigerant is compressed to very high pressures in the compressor, while its temperature is also raised. When the refrigerant enters a compressor, it is in a gaseous state at low pressure and low temperature and exits the compressor at high pressure and high temperature in a gaseous state.

Types of Compressors

Compressors fall into two types: reciprocating compressors and rotary compressors.

Similar to reciprocating engines, reciprocating compressors have pistons and cylinders. Reciprocating engines consume fuel to produce power, whereas reciprocating compressors consume power to produce compression. Reciprocating compressors can also be powered directly by engines. Compression occurs as a result of the piston reciprocating inside the cylinder.

A rotary compressor has a rotating rotor that compresses the refrigerant inside a closed chamber.

Compressors require power to operate. Rotary compressors consume less power than reciprocating compressors. Reciprocal compressors even generate more noise than rotary compressors. Also, reciprocating compressors require more maintenance than rotary compressors. Because of these factors, rotary compressors have quickly replaced reciprocating compressors, not just in heat pumps but also in air conditioners.

By the second law of thermodynamics, a heat flow occurs from a source or a reservoir of hot, high temperatures to a sink or reservoir of cold, low temperatures. Heat must be transferred from low-temperature reservoirs to high-temperature reservoirs by means of external work. The heat pump transfers heat from a low-temperature atmosphere to a high-temperature room, so it needs some external power supply.

Heat pumps require electric power to run the compressor, which is supplied by the external work. When it comes to heat pumps, refrigerators, freezers, and air conditioners, it is the compressor that consumes the most energy. This compressor performs the crucial task of compressing the refrigerant in order to transfer heat from a low to a high-temperature reservoir.

Condenser

The next important component of a heat pump is the condenser. Heating is one of the functions of a heat pump, and the condenser produces this effect inside a room. The refrigerator’s main function is to cool the substance or material, and the evaporator produces this effect. Whereas the evaporator is the main component in refrigerators that produces cooling, the condenser is the main component in heat pumps that produces heating. An air conditioner’s condenser is located outside the room that must be cooled, but a heat pump’s condenser is located inside the room.

It is extremely hot and very pressurized when the refrigerant leaves the compressor. The refrigerant is then sent to the condenser, which is typically made from copper coils. As a result of high temperatures in the refrigerant, the coil inside the condenser also becomes very hot, creating heat inside the room.

Air is blown over the hot condenser coil by a fan or blower located behind the condenser coil. Heat is transferred to the air as it passes through the coil of the condenser, and the heated air is expelled into the room, making it hot. The hot air is thrown into the room while the air is absorbed continuously by the fan. The room is kept at a much higher temperature than the surrounding air. When it comes to condenser coils, two types of fans can be utilized: forced and induced fans.

The condenser’s temperature and the temperature of the refrigerant inside it decrease when air passes over it since air absorbs the heat from the condenser. The refrigerant leaves the condenser at high pressure and medium temperature, partially in the liquid state and partially as a gas. Next, it will enter the expansion valve or capillary tube, which plays an important role.

Expansion Valve

The expansion valve reduces pressure. The refrigerant entering the expansion valve at high pressure and medium temperature suddenly experiences a decrease in pressure and temperature. In heat pumps, copper capillary tubes are the most common expansion valves. Expansion valves release refrigerants in partially liquid and partially gaseous states when pressure and temperature are extremely low.

Evaporator

Air conditioners have their evaporators inside the room, but heat pumps have their evaporators outside the room and are exposed to the local atmosphere, which is extremely cold. The copper coil also makes up the evaporator, just like the condenser. By entering the evaporator coil at low pressure and low temperature, the refrigerant drastically reduces the coil’s temperature to an even lower level than the atmospheric temperature.

Due to the low temperature of the refrigerant inside the evaporator, it tends to absorb the heat from the surroundings. With the blower or fan, the air is blown over the evaporator, giving up its heat to the refrigerant and heating it. Due to its capability to absorb heat from atmospheric air, the refrigerant’s temperature increases. However, its pressure remains constant, and it becomes a gas.

The refrigerant in gaseous form is introduced into the compressor at low pressure and medium temperature. Compressors compress refrigerants to extremely high pressures and high temperatures in gaseous form. The refrigerant is then directed into the heat pump’s condenser, where it heats the air in the room. Thus, the cycle continues. During each cycle, the refrigerant flows continuously through the closed cycle and is heated and cooled. Heat pumps and refrigerators use refrigerants that can undergo phase changes without being subjected to any chemical changes.

Refrigerant

In addition to the four essential components, the refrigerant is another equally important part of a heat pump. Heat pumps use the same refrigerant as refrigerators and air conditioners. Chlorofluorohydrocarbons are among the most common refrigerants, but a variety of other alternatives have also been discovered.

A closed cycle is created by the refrigerant flowing continuously through the compressor, condenser, expansion valve, and evaporator. The refrigerant is responsible for conveying heat from low temperatures in the atmosphere to higher temperatures in the room.

As with chlorofluorohydrocarbons used in refrigerators and air conditioners, chlorofluorohydrocarbons used in heat pumps cause a range of problems and concerns for the environment. It is believed that chlorofluorohydrocarbons destroy ozone at the Earth’s surface and trigger greenhouse effects.

The total number of heat pumps in the world is still much lower than that of air conditioners, refrigerators, and freezers, so they do not receive as much attention as to whether or not they deplete the ozone layer. However, as with the other chlorofluorohydrocarbons whose production has to be completely phased out, so too must the production of the refrigerant used in heat pumps be shut down in the same manner.

Accumulator

An accumulator is another component found in most heat pumps. This tank may be visible if you follow the compressor suction line downward from the compressor. Its purpose is to hold any liquid surge before getting to the compressor. The accumulator collects the excess liquid refrigerant that did not evaporate in the evaporator. In this case, the liquid will boil off and become a vapor, which can be safely returned to the compressor. If the liquid were to enter the compressor, it would cause damage. Not every brand and model has an accumulator.

Compressor Contactor

A compressor contactor serves two purposes. When the thermostat is adjusted for heating or cooling, the compressor and fan motor are triggered by the compressor contactor. Faulty contactors often lead to heat pump problems. In time, the continuous arcing of the contacts burns away their finish.

Crankcase heater

An air-source heat pump uses a crankcase heater to raise the temperature of the compressor oil or to keep the compressor oil warm. As a result, the refrigerant vaporizes, preventing it from mixing with the oil. If there is an increase in the volume of liquid, it will put a strain on the compressor. This may damage the compressor.

ECM

ECMs, or electronic commutated blower motors, are brushless direct current motors that are used in heat pumps because they have higher efficiency, can work at a wider range of speeds, and consume less power than other motors. They can be found on most high-efficiency two-stage or multistage heat pumps. The permanent split capacitor blower motor, or short PSC, is another type of motor that usually appears on standard heat pumps.

Reversing valve

A reversing valve automatically controls the direction of the refrigerant flow. As a result, the heat pump switches from cooling to heating mode and vice versa. During the defrosting cycle, it is regulated by the thermostat or defrost control. Troubleshooting and replacing the reversing valve is very easy during a failure. Defrosting is undertaken or ended by reversing the valve. In doing so, pressure in the system equalizes, causing the “whooshing” sound.

Thermostatic Expansion Valve (TXV)

The thermostatic Expansion Valve is located on all fan coils and furnace coils. It maintains a predetermined superheat temperature at the evaporator coil’s exit according to changes in load conditions.

Thermostats

Using a thermostat, you can control and monitor the temperature, providing a more comfortable environment.

Defrost system

It is possible for evaporator coils to become frosty when the ambient air temperature drops below 32 F (0 C), and the air-to-air heat pump is working in heating mode. Consequently, there is less airflow and less efficiency since the evaporator is unable to extract heat.

Defrosting systems are therefore required (only air-sourced HP), so heat from the compressor can be directed to the outdoor coil and melt ice there. It is a very short-lasting cooling mode that has no effect on the indoor climate. Defrosting can be done on a time and temperature basis or on-demand, which is preferable.

Fan

The fan consists of the fan motor and fan blades. Based on the orientation of the fan blade, the system will either pull or blow air, and through the outdoor coil, it will exchange heat between the refrigerant and surrounding air. New models always have lubricated bearings, so routine maintenance does not involve lubrication.

Motors

On fans and blowers, variable-speed or dual-speed motors are better than standard motors as they provide better air velocity and are quieter.

Motors start with the help of start capacitors. They provide an initial boost to the compressor. Motors draw quite a bit of current when starting. Not all heat pumps have starter capacitors. But they can be added as an option.

In some cases, a technician may have installed a start capacitor on your HVAC unit because the compressor had problems starting, or he was a good salesperson and explained its benefits.

Compressors with start capacitors have starting amps about half those without. A potential-start relay is another part. Upon startup, the capacitor can be taken off line within a short time.

Refrigeration Coils

Refrigeration coils are made of aluminum fins and copper tubing, making them extremely fragile. Hail storms and kids with bikes bend and close the fins, reducing efficiency. In coils with bent fins or cottonwood tree material sucked in, the air is less likely to flow through them, resulting in less heat transfer.

Function

A heat pump transfers heat, and It is the most critical characteristic of all heat pumps. Essentially, it works the same way as compression refrigeration, except the primary focus is not on the evaporator i.e. the cold side, but on the condenser, where the heating action occurs. In principle, the process is the same:

- The evaporator evaporates the refrigerant.

- The compressor increases pressure and, therefore, temperature.

- The condenser liquefies the refrigerant and the refrigerant after it has expanded through the throttle valve.

In addition, the refrigerants used are not much different from those in an ordinary refrigeration system. The most popular refrigerants for heat pumps are R407C, R410A, and R134a.

Heat Pump in Air Conditioning Setting

A heat pump will help you maintain cool, comfortable temperatures and control humidity levels in your home when it is installed and functioning properly.

- A motorized fan draws warm air into ductwork from inside your home.

- It consists of a compressor that moves the refrigerant from the indoor evaporator to the outdoor condenser.

- Warm air from the indoors moves to the air handler, and refrigerant from the exterior coils is pumped to the interior evaporator coils. As the refrigerant passes through the air indoors, it absorbs heat.

- Air that is cooled and dehumidified is then transferred to home air vents by connecting indoor ducts. This lowers the interior temperature.

- As the cycle repeats, you are kept cool consistently.

Heat Pump in Heat Setting

There have been heat pumps installed for many years in places that have milder winters. Currently, air-source heat pumps can be used in areas with extended periods of subfreezing temperatures due to technological advances.

A heat pump can switch from air conditioning to heating by reversing the refrigeration cycle, which makes the outside coil act as the evaporator and the indoor coil as the condenser.

- The refrigerant circulates between the indoor and outdoor units through a closed system of refrigeration lines.

- Even though outdoor temperatures are cold, enough heat energy is drawn from the outside air by the condenser coil and released inside by the evaporator coil.

- A motorized fan pulls air from inside your home into the ductwork.

- Upon absorption of heat from the air, the refrigerant is pumped out of the interior coil into the exterior coil.

- Afterward, the warmed air is circulated through ducts to air vents throughout the house, increasing its temperature.

- The refrigeration cycle is repeated, keeping you warm consistently.

FAQs about Parts of Heat Pump

What are the four major working parts of a heat pump?

- Compressor: The compressor is the heart of the heat pump. It uses electricity to compress the refrigerant, which increases its pressure and temperature.

- Condenser: The condenser is located on the outside of the heat pump. It is where the refrigerant releases heat into the surrounding air.

- Evaporator: The evaporator is located on the inside of the heat pump. It is where the refrigerant absorbs heat from the air inside the home.

- Expansion valve: The expansion valve is a small device that reduces the pressure of the refrigerant, which causes it to change from a liquid to a gas.

These four parts work together to transfer heat from one place to another. When the heat pump is in heating mode, it absorbs heat from the outside air and transfers it to the inside air. When the heat pump is in cooling mode, it absorbs heat from the inside air and transfers it to the outside air.

Heat pumps are a great way to save energy and money on your home heating and cooling costs. They are also a more environmentally friendly option than traditional heating and cooling systems, such as furnaces and air conditioners.

What is the outside part of a heat pump called?

The outside part of a heat pump is called the condenser. The condenser is where the refrigerant releases heat into the surrounding air. The condenser is typically made of metal and has fins that help to increase the surface area of the refrigerant. This allows the heat to be released more efficiently.

Here are some of the functions of the condenser:

- Releases heat from the refrigerant into the surrounding air.

- Converts the refrigerant from a hot gas to a cool liquid.

- Compresses the refrigerant, which increases its pressure and temperature.

- Regulates the flow of refrigerant through the heat pump.

The condenser is an important part of the heat pump and it is important to keep it clean and free of debris. If the condenser is dirty, it can reduce the efficiency of the heat pump and make it work harder. This can lead to higher energy bills and shorter lifespan of the heat pump.

What is the indoor part of a heat pump called?

The indoor part of a heat pump is called the evaporator unit. It is where the refrigerant absorbs heat from the air inside the home. The evaporator unit is typically made of metal and has coils that help to increase the surface area of the refrigerant. This allows the heat to be absorbed more efficiently.

Here are some of the functions of the evaporator unit:

- Absorbs heat from the air inside the home.

- Converts the refrigerant from a liquid to a gas.

- Expands the refrigerant, which lowers its pressure and temperature.

- Regulates the flow of refrigerant through the heat pump.

The evaporator unit is an important part of the heat pump and it is important to keep it clean and free of debris. If the evaporator unit is dirty, it can reduce the efficiency of the heat pump and make it work harder. This can lead to higher energy bills and shorter lifespan of the heat pump.

What is the core component of a heat pump?

The core component of a heat pump is the compressor. The compressor is a mechanical device that increases the pressure and temperature of the refrigerant. This is necessary for the heat pump to be able to transfer heat from one place to another.

The compressor is typically powered by an electric motor, but it can also be powered by other sources, such as solar power or geothermal energy. The compressor is the most important part of the heat pump, and it is responsible for the majority of the energy consumption of the system.

There are two main types of compressors used in heat pumps: reciprocating compressors and scroll compressors. Reciprocating compressors are the most common type of compressor used in heat pumps. They are relatively simple to design and manufacture, and they are relatively efficient. However, reciprocating compressors can be noisy, and they can vibrate, which can lead to problems with the heat pump.

Download Parts of Heat Pump PDF

Downloading the PDF version of this article is one option we included in order to provide you with access to this content. Start by clicking the link below.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Heat Pump & How Does it Works?

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- 8 main Parts of Piston Pump and Function + Work & PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 20 Parts of Submersible Pump + PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- Parts of Water Pump

- Parts of Centrifugal Pumps

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 20 Parts of Submersible Pump + PDF

- 6 Parts of Pool Pump + Diagram & PDF

- Best Check Valve for Sump Pump: 9 of the Best Models

- What is Sump Pump and How Does It Work?

- Top Dosing Pump Manufacturers and Suppliers in 2022

- Top Water Pump Manufacturers and Suppliers in 2022

- The 7 Best RV Water Pump In 2022 (Clear Guide + Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 10 Parts of Hydraulic Pump + PDF & Function

- Parts of Oil Pump

- Types of Centrifugal Pumps: All Classification & Working Principles

- Centrifugal Pump Working Principle with Diagram

- Top 10 Heat Pump Manufacturers and Suppliers in USA & Worldwide in 2022

- The 5 Best Air Source Heat pump in 2022

- 16 Parts of Heat Pump and Functions (Clear Guide)

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- Understanding Heat Pumps in Winter: How Do They Work?

- Heat Pump Efficiency: Equation & Formula

- How Does a Heat Pump Work?

- What Are Air Source Heat Pumps? A Complete Guide

- What Is a Heat Pump Reversing Valve?

- Best Mini Split Heat Pump for Cold Weather in 2022

So detailed, thanks for sharing.

Thank you so much, Arical! We also encourage you to visit our other posts, where you can find more information about Heat Pumps and other instruments.

I believe that 1/1/23 is start date for switch for A/C units to 600 series refrigerants. My understanding is that these are actually flammable. I’m confused as so many residential setups have heaters/ water heaters with pilot lights placed in the same location. Does this refrigerant switch also apply to heat pumps?

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various heat pumps based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.