Foot Valve: Working Principle & Function

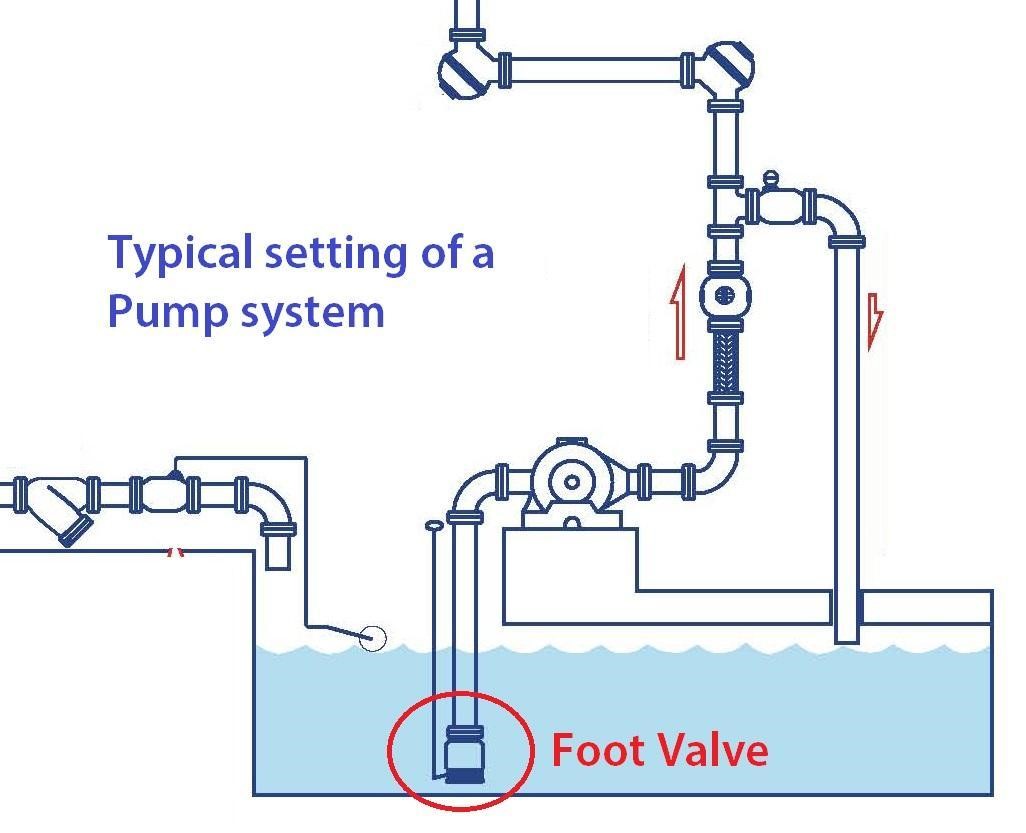

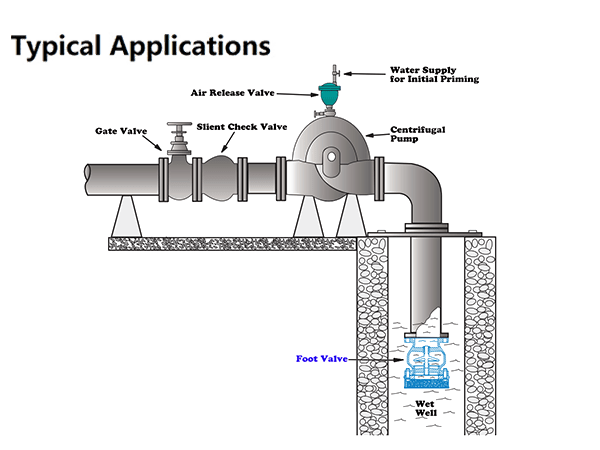

Foot Valves are used as a lift check valve in the suction line, usually in conjunction with suction strainers. As a result, after the pump has stopped, the suction line does not run dry. Foot valves are pieces of industrial equipment that are fitted to ensure that the valve, the sump floor, and the lowest suction level are all at the same level. A foot valve is a type of check valve that only allows one flow direction. When a pump is necessary, such as when water must be pumped from underground wells, foot valves are perfect. Because they are lightweight and cost-effective, PVC foot valves are an ideal choice for most applications. Metal valves are available in a range of materials, including brass and stainless steel, and are perfect for applications requiring specific chemical resistance, as well as temperatures and pressures that are incompatible with PVC.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Foot Valve

Top Devices in Foot Valve

What Is Foot Valve?

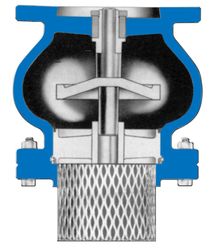

This type of check valve is usually found on a pump or at the base of a pipeline (hence its name). A foot valve works like a ball check valve but has an open end covered by a shield or screen to prevent debris from entering the line. Valve openings are designed larger than the line itself in order to minimize head loss.

You can find foot valves in pools, ponds, and pretty much anywhere there is a pump. Using these special valves, the pump can remain primed, allowing liquid to enter, but preventing it from backing out. In ponds and wells, screens or baskets covering the valve opening usually become clogged over time. Regularly checking and cleaning your valves will ensure optimal performance.

Working Principle of a Foot Valve

In this section, we will discuss the operation principle of foot valves and how they help keep pumps primed and protect them from damage.

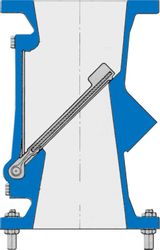

An application with a suction lift uses the foot valve at the end of the pipeline. In addition to working as a check valve, they also come with a strainer on their open end. Check valves are spring-assisted. Pumping causes a change in pressure within the pump column, and as a result, the valve opens. The valve responds by closing again when the pump is stopped. By doing so, the pump is prevented from losing its prime as fluid drains out of its column when it is turned off.

A strainer keeps debris away from the pump, so it is vital. Similar to vertical turbines, multistage pumps have tight tolerances. Even the tiniest amount of debris can adversely affect the pump. The strainer also prevents debris from getting stuck in the foot valve. As a result, the valve would be stuck in the open position, and all of the fluid would drain from the pump column. In some foot valves, the mesh is fairly tight, whereas, in others, the grid strainer is wider. You can adjust the mesh size according to your application.

You can find a great deal of foot valve Companies and Manufacturers in Linquip, along with expert Service Providers.

Components of a Foot Valve

A foot valve consists of four main parts. Different companies use different technologies to make their valves. Even though these foot valves differ in size and application, they all share several components. The following are the basic components of all valves of this type.

Screen

Foot valves are equipped with screens to keep out any debris or sediment that may come up from the pump suction end. Materials such as stainless steel, brass, and plastic are frequently used to make these screens. It plays an important role in the lifespan and efficiency of the valve, even though it is just a simple screen. Plastic screens are typically used for light-duty applications like small tanks, while stainless steel and brass are typically used for heavy-duty applications.

Body

Since the entire mechanism of the valve is contained within the body, this is the most important part of the valve. Cast iron and brass are the most common materials used for the body of heavy-duty valves. These kinds of valves are also used for heavy-duty loads and can be larger than 10 inches in diameter. The smaller ones are usually made from hard plastic, PVC, or stainless steel. Lower pressure and lighter duty are the applications of these valves.

Seat

It is also an essential component of a foot valve because it is the place where the valve lands when the pump is turned off. Seats are integral parts of the body, and it is at the seat that an O-ring, made of rubber or silicone, is placed in order to prevent leakage when the valve is closed. This part of the valve wears down faster than the rest because fluid passes through it constantly.

Disc

In essence, this is the valve's door or gateway. Upon starting the pump and getting water flowing through the valve, the disc elevates, allowing water or any fluid to pass. Bronze, brass, and steel, which have longer lifetimes than plastics and stainless steel, are the most commonly used heavy metals for discs.

Function of a Foot Valve

Generally, foot valves have an inlet strainer, which filters the incoming water and prevents damage to the valve. Electric pumps are applied to pump the water from the lower level to the higher level, which would use much energy. Foot valves are located at the very bottom of the pick-up line, so they are at the lowest point on the pipe. Water is picked up from the lower level by using a pump. The pump creates suction, and on account of the upward pressure, the foot valves open, allowing the water to flow from the lower level.

But if the pump is turned off, gravity will cause the water to flow back to the lower level, which can be prevented with foot valves. This means that the water column in the pipes will be maintained, and all issues will be resolved.

Foot valves are a check valve type, and they can only open in one direction, so they can only allow unidirectional flow, and they close when the flow direction is reversed.

Linquip offers a wide range of foot valve Distributers, Experts, and Equipment for Sale.

Usage of Foot Valves

By controlling the flow of the pump column, foot valves can prevent the pump from draining when the pump is turned off. Foot valves are widely utilized in a variety of pneumatic systems. Additionally, they are used in the suction line of the pipeline. Whether operating at low or high pressure, a positive seal can be achieved without slamming. It has a spring load closing mechanism and can be mounted in any direction. Low head loss is a characteristic of foot valves. It is possible to maintain hydraulic pressure with foot valves.

Common Applications of Foot Valves

Foot valves can be used for:

- Underground water extraction

- industrial purposes

- Fire protection in rural areas

- HVAC

- Irrigation

- Car wash system

Material of Foot Valves

Foot valves are made of the following materials:

- Brass

- Plastic

- Stainless Steel

- Aluminum

- Carbon steel

- Cast iron

- Copper

- Nickel

- Rubber

Features of Foot Valves

There are certain characteristics that make foot valves suitable for specific applications.

- For easy installation, most foot valves feature self-tapping male and female threads.

- There are internal balls that allow quick seal and valve reaction.

- They are flexible enough to be used for various types of water pump applications. Foot valves are used, for example, in the development of wells and the sampling and purging of volatile organic compounds.

- Compared to other valves, foot valves are cheaper.

- The majority of foot valves are made of cast iron, bronze, and PVC.

- They can last longer when submerged in water.

- A foot valve must be installed vertically with an arrow pointing up in the direction of liquid flow.

- An installation of the foot valve must be made at a vertical distance of at least 25 feet below the pump inlet.

FAQ about Foot Valve

- What is the use of foot valve?

Foot valves are lift check valves that are generally placed together with suction strainers along the suction line. After the pump is stopped, it keeps the suction line from becoming empty.

- How does a foot valve work?

A foot valve works as a check valve, but it is also attached to a strainer. The pressure in the pump column changes when the pump is turned on, therefore the valve opens.