Are you interested in learning about the Functions of A Gearbox? You can find the essentials of a Gearbox, its operating principle, classifications, and its applications here at Linquip. Are you looking to purchase Gearbox Equipment? You are invited to browse our Gearbox For Sale at Linquip, where you have access to See a List of All Gearbox Products in Linquip based on your application and requirements.

Moreover, Linquip provides a comprehensive list of Gearbox Suppliers and Companies so that you may select the right one for your needs. Linquip offers a wide selection of Gearbox manufacturers who can assist you in finding the right equipment for your application. A Gearbox Service Provider can also help you manage your industrial equipment service activities, including installs, maintenance, and repairs.

The gearbox is an essential component of machines used in various industries and fields. The purpose of gearboxes is to increase the output torque or to change the speed (RPM) of a motor. The shaft of the motor is connected to one end of the gearbox and through the internal configuration of gears, provides a given output torque and speed determined by the gear ratio. Gearboxes are used in agricultural, industrial, construction, mining, and automotive equipment and are available in different designs and specifications. In this article, we will take a closer look at different types of gearboxes and their main features. Follow this new blog in Linquip to learn more about these types of gearbox with images.

⇒ View a List of Gearbox for Sale and Their Suppliers ⇐

Different Types of Gearbox

- Industrial gearbox

- Helical gearbox

- Coaxial helical inline gearbox

- Bevel helical gearbox

- Skew bevel helical gearbox

- Worm reduction gearboxes

- Planetary gearbox

- Automobile gearbox

- Manual transmission

- Sliding-Gear Transmission

- Constant-Mesh Transmission

- Pre-selector Transmission

- Automatic transmission

- Torque Converter

- Automated-Manual Transmission

- Dual-clutch transmissions (DCT)

- Continuously variable transmission (CVT)

As mentioned above, gearboxes have a wide range of applications. Here we will explain the classification of gearboxes and introduce the main types of industrial gearboxes and automobile gearboxes.

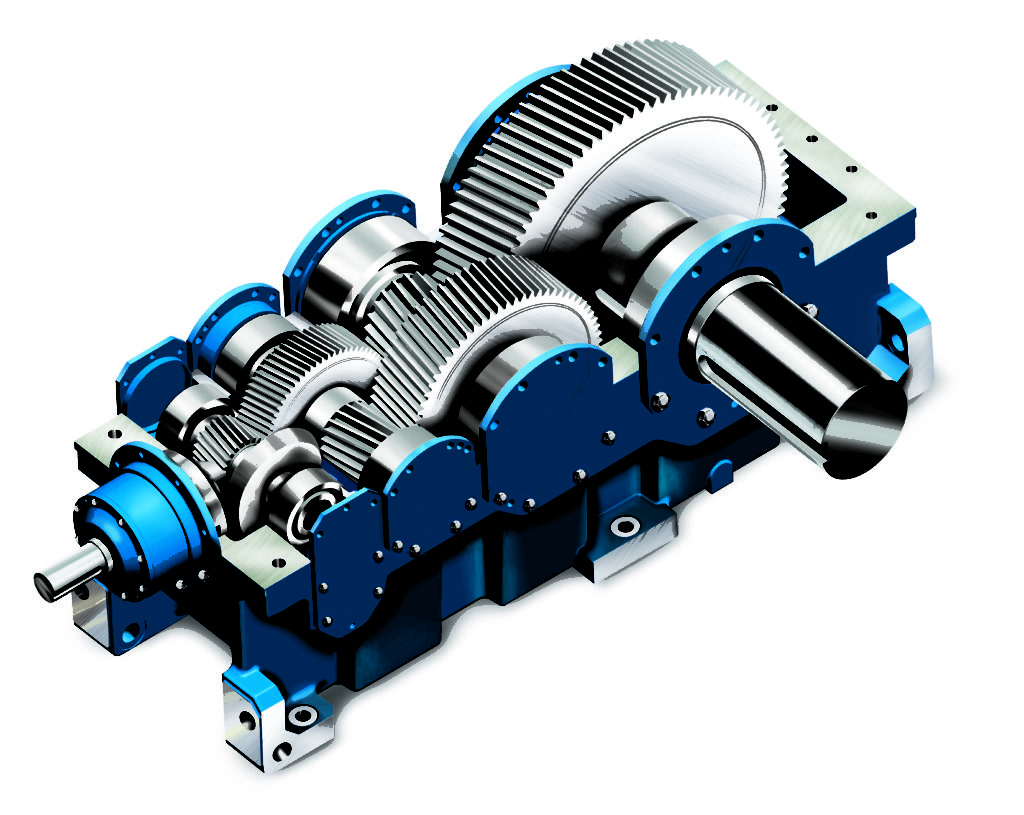

Different Types Of Industrial Gearboxes

The 6 main types of industrial gearboxes are described below.

-

Helical Gearbox

The helical gearbox is compact and a low-power consumer. This equipment is used for a broad range of industrial applications, but typically in heavy-duty operations. The helical gearbox is popular in the construction of plastics, cement, rubber, and other heavy industrial settings. It is useful in crushers, extruders, coolers, and conveyors, which are all low-power applications.

The helical gearbox is unique in that it is fixed at an angle that when in motion, enables more teeth to interact in the same direction. This provides constant contact for a given period.

-

Coaxial helical inline gearbox

The coaxial helical gearbox is ideal for heavy-duty applications. Coaxial helical lines are noted for their quality and efficiency. These are manufactured with a high degree of specification, which allows you to maximize load and transmission ratios.

Bevel helical gearbox

The critical feature of this type of gearbox is a curved set of teeth located on the cone-shaped surface close to the rim of the unit. The bevel helical gearbox is used to provide rotary motions between non-parallel shafts. These are typically used in quarries, the mining industry, and conveyors.

-

Skew bevel helical gearbox

The skew bevel helical gearbox is notable for its rigid and monolithic structure, which makes it usable in heavy loads and other applications. These industrial gearboxes offer mechanical advantages once they are mounted on the correct motor shaft output. These are highly customizable based on the number of teeth and gears. Therefore, you can usually find one suitable for your needs.

-

Worm reduction gearboxes

Worm reduction gearboxes are used to drive heavy-duty operations. These gearboxes are used when there is a need for increased speed reduction between non-intersecting crossed-axis shafts. This type of industrial gearbox uses a worm wheel that has a large diameter. The worm, or screw, meshes with the teeth on the peripheral area of the gearbox. The rotating motion of the worm causes the wheel to move similarly due to the screw-like movement. Most of these industrial gearboxes are used in heavy industries such as fertilizers, chemicals, and minerals.

-

Planetary gearbox

A Planetary Gearbox has a central Sun Gear and is surrounded by three of four Planet Gears. These are all held together through an outer ring gear with internal teeth. This design spreads the power equally through the gears and enables a Planetary Gear System to achieve a high torque in a small space. This type of Gearbox is popular in cutting-edge technologies like robotics and 3D printing.

The planetary gearbox is ideal for its endurance, accuracy, and distinct functionality and is notable for its precision applications. This type of gearbox increases the lifespan of your equipment and optimizes performance. Planetary gearboxes come in either a solid type of hollow format or with a variety of mounting options including a flange, shaft, or foot.

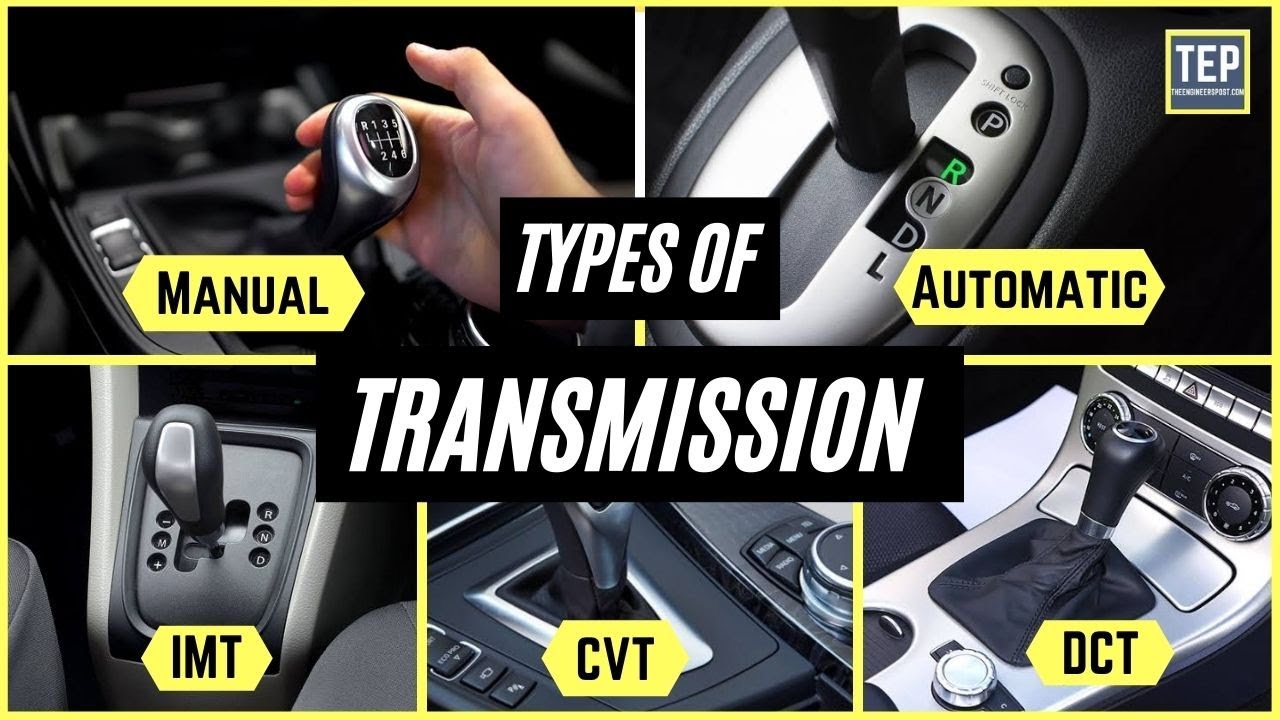

Different Types Of Automobile Gearbox

Different types of gearboxes in an automobile are described below.

Manual transmission

With a manual transmission, the driver selects all gears manually using both a movable gear selector and a driver-operated clutch. This type of transmission is also known as a “stick shift” or a “standard” transmission.

This setup gives the driver full control over the gears, allowing them to either drop a gear to make quicker progress or choose a higher gear to save fuel. The major types of manual transmission are listed below.

Sliding-Gear Transmission

Sliding-gear transmissions are only found on older model cars. When the transmission is in neutral, the only things that move within the transmission case are the main drive gear and cluster gear. To send power to the drive wheels (either front or rear), the clutch pedal must be depressed so that the shifter handle can be moved. Moving the shifter handle changes the position of the shift linkage and forks and slides a gear along the main shaft directly above the cluster gear.

Once these two gears have meshed, the clutch can be released. To change gears again, drivers are required to unmesh the current gear before synching two new gears. With this type of transmission, not all of the gears have the same diameters and tooth numbers. The different diameters cause the gears to rotate at different speeds and this can cause gear clash. This problem is one of the main reasons this type is no longer used.

Constant-Mesh Transmission

Also known as synchronized transmissions, constant-mesh transmissions keep the drive gear, cluster gear, and main shaft gears in constant motion. This is possible because the gears are free to spin around the main shaft. A dog clutch is used to lock these gears into place when they’re needed. When the shift linkage moves, teeth on the dog clutch and main shaft gears lock onto each other and hold the gear stationary. Synchronizers are used in constant-mesh transmissions to prevent any clashing or grinding while shifting.

Pre-selector Transmission

As with all things, manual transmissions went through a series of evolutions and variations as car manufacturers experimented with design. One manual transmission type developed before the introduction of automatic transmissions was called the Wilson Pre-selector.

Introduced in 1930, this transmission used a planetary gear system to preselect gear ratios using a small lever on the steering column. To shift gears, the driver presses down on a foot pedal that calls up one of the preselected gears. When this happens, the previous gear is disengaged at the same time that the new gear engages.

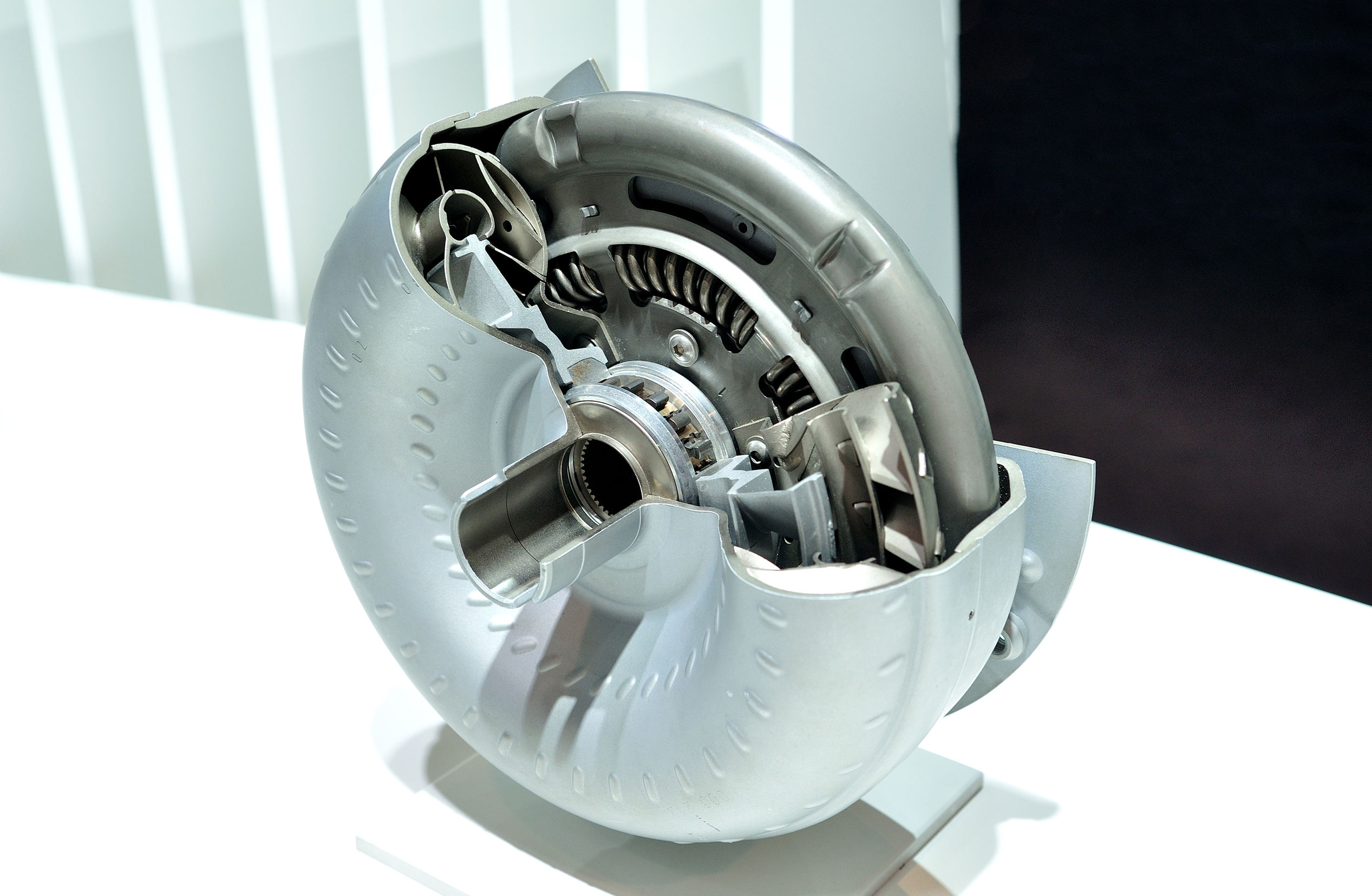

Automatic transmission

While almost manual gearboxes follow the same basic principles, automatic transmissions are a whole different thing altogether. Regardless of the mechanical workings going on beneath the surface, any automatic transmission will look pretty familiar to the driver; Park, Reverse, Neutral, and Drive, maybe with additional functions like Sport or a manual shift mode. A gear lever on an automatic transmission is simply an electronic switch that sends an instruction to the software that manages the gearbox. As a result, we’ve started to see designers choosing to use buttons, paddles, or dials instead of old-style levers for controlling the transmission.

Torque Converter

The most common type of automatic gearbox uses a torque convertor to transfer the engine’s rotational force to the wheels. A torque converter is a fluid coupling that lets the car pull away and stop without stalling the engine, though there is some loss of efficiency as it takes up drive due to the curved shape of the turbine blades inside the converter. The advantage of this type of transmission is the smooth acceleration from low speeds, as well as good responsiveness at low engine revs.

Automated-Manual Transmission

The automated-manual transmission is a type of automatic transmission that uses a regular clutch and gear configuration but makes use of sensors, actuators, processors, and pneumatics to simulate manual gear use. These types of vehicles are known for jerky engine performance at low speeds and hard acceleration but can get high fuel mileage over long distances.

Dual-clutch transmissions (DCT)

This type of gearbox is fast becoming the most common kind of automatic transmission for petrol and diesel cars. Most Volkswagen Group brands; VW, SEAT, and Skoda call it a DSG (direct shift gearbox), although Audi confuses matters further by calling it an S-Tronic and Porsche prefers the name PDK, they’re all the same thing.

As the name suggests, there are two clutches in play with these gearboxes. In its most basic form, there will be two separate clutch systems; one for the odd-numbered gears and another for the even-numbered gears.

The gearbox can therefore pre-select the next gear before a shift happens, which means the shifts are considerably faster than with other types of gearboxes. In performance cars, this has been developed to the point where gear changes are almost imperceptible.

This type of transmission offers the same sort of direct feel as a single clutch version but is usually far smoother and more efficient to drive. It can also usually offer better fuel economy and performance than a manual gearbox. There can still be some jerkiness at low speeds, and it can be a bit clunky when moving between first and reverse gears.

Continuously variable transmission (CVT)

A CVT doesn’t have gears at all. Instead, it uses a cone shape with a band around that and another axle. The band can be moved up and down the cone to vary its length and therefore the gear ratio. Theoretically, it offers infinitely variable ratios between its upper and lower limit, meaning it can be perfectly optimized for fuel efficiency or performance at any given time. This is particularly helpful for hybrid cars, which can use a CVT to balance the workload between the petrol engine and electric motor.

The downside is a driving experience that tends to feel bizarre and often unpleasant. When accelerating, it feels like the car is pulling against a rubber band. Meanwhile, the accompanying noise has a horrible drone because the revs go straight to the peak power point and stay there as the car picks up speed, rather than rising and falling as you work your way through multiple gears. The latest gearboxes are improving, so there’s a chance that the CVT will have its day in the sun soon.

So, this is all you need to know about the different types of gearboxes. If you enjoyed this article in Linquip, let us know by leaving a reply in the comment section. Is there any question we can help you with? Feel free to sign up on our website to get the most professional advice from our experts.

What Are The 3 Types of Transmission?

Automobiles are always developing, changing, and becoming more efficient. This also applies to transmission. Manual, automatic, and CVT transmissions are the three types of gearboxes in use, each targeted toward unique purposes and driving styles.

Download Gearbox Types PDF

For a better understanding of the basics of industrial gearboxes, their working principle, and types look at this PDF that can help you better understand gearboxes.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Gearbox Components and Parts: Everything You Need to Know

- Industrial Gearbox A Comprehensive Review on Features, Types, and its Usability

- What is Gear Shaft?

- Types of Bevel Gears

- What is a Bevel Gear and How Does it Work?

- What is a Helical Gearbox?

- Differences Between Worm and Helical Gear

- Types of Induction Motor: A Concise and Useful Guild

- All About DC Motor Types and Their Applications

- Types of Heat Exchangers: An Introduction to All Essential Specifications

- What is a Worm Gearbox?

- What is Planetary Gearbox and How Does it Work?

- The difference between gearbox and transmission

A very useful article for lecturer of English language, as foreign one, who teaches students in technical college. We have been using old text-books since 1990-ths. Classification of site “https://lemonbin.com/types-of-car-transmission/” was previously useful, but nowadays is out-of-date.

Thanks for visiting our website and leaving your comment, Yuriy! You are encouraged to visit Linquip Tech News, where you can find similar posts.

thanks for sharing this information with us this is a very useful and unique article I have read this it is a very informative about gearbox

Thanks for visiting our website and leaving your comment! You are encouraged to visit Linquip Tech News, where you can find similar posts.