Anyone who deals with metal, including welders and jewelry makers, is aware that, in contrast to the gluing of materials like wood, plastic, or glass, the gluing of metal to metal or metal to another surface takes extensive planning. It is crucial to utilize a metal-specific adhesive to create the strongest bond possible.

Metal glue has a history of producing erratic results, although contemporary adhesives may successfully attach metal and a range of other materials.

Many different suppliers, businesses, manufacturers, and distributors provide glues for metal, and Linquip offers a vast assortment of Glues for Sale. Linquip offers a thorough range of services for all OEM fleets. Please get in touch with Glue Experts to find out more about how to establish connections with a wide range of Service Providers who consistently deliver high-quality goods.

Metal gluing can be difficult for a variety of reasons. Glues cannot penetrate the surface of metals because they are not porous. Metals typically have a relatively smooth surface and offer little to no grip. Because metal objects are frequently used outside, glues must be able to endure extremes in temperature, water, and maybe salt or chemicals.

These obstacles have been solved by contemporary adhesives, making it possible to combine glass, fabric, wood, and metal. The proper product must be chosen based on an understanding of the features that are required from the adhesive because there is no one solution that works for every circumstance and type of bond. Continue reading to learn how to choose the best metal glue for several applications and to see some of the top choices in a few common instances.

The best approach to use while attaching metals can be difficult to select. The old-fashioned weld or solder may provide a reliable solution, but the time, knowledge, and skill needed frequently surpass the task at hand. A high-quality glue, on the other hand, will enable you to attach metals to a variety of different materials for a fraction of the cost and effort while also achieving a real bond between metals.

You might need to explore outside the arts and crafts box to get the best adhesive for the job because metals are non-porous, slippery materials that can frequently slip away from many household tubes of glue. The three adhesives listed below often perform best with metal:

- Epoxy – A two-part adhesive that combines hardener and resin for a quick-curing and incredibly strong bond.

- Polyurethane – This glue is a great choice for outdoor applications because it is UV and water-resistant.

- Cyanoacrylate – This straightforward adhesive, better known to you as “super glue,” provides prompt but effective effects.

We’ve compiled a list of goods we think would be useful for your quest for the ideal metal glue, covering a range of price points and applications. For your peace of mind, we checked consumer reports and product reviews to make sure actual customers were delighted with the functionality and performance of each adhesive. You can also visit this link to explore more about them.

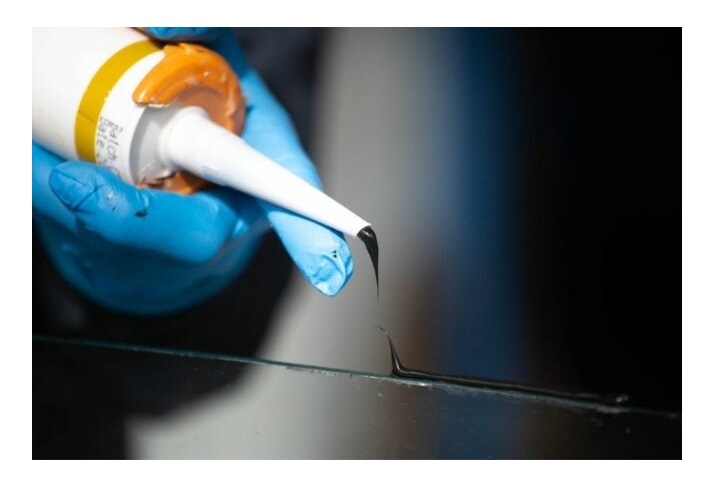

Cleaning out any corrosion, paint, or dirt from the metal is the first step in preparing it for glue adherence. Next, the area to be bonded must be sanded, being careful not to leave any fingerprints behind. Safety gloves are strongly advised because most metal glues are hazardous and shouldn’t be applied to the skin. Additionally, wearing a protective mask is essential to prevent inhaling the hazardous fumes from the glue, as is using the glue in a location that is well-ventilated, ideally outside.

List of 12 Best Glues for Metal in 2024

According to the factors that we will mention in this article, Here is the List of 12 Best Glues for Metal in 2024:

- J-B Weld 8271 KwikWeld Professional Size Buy Now

- 3M Marine Adhesive Sealant Fast Cure Buy Now

- Loctite Super Glue Ultra Gel Control Buy Now

- Aleene’s Jewelry & Metal Glue Buy Now

- Gorilla Original Glue Buy Now

- Liquid Nails Fuze It Max Buy Now

- Permatex PermaPoxy 4 Minute Multi-Metal Epoxy Buy Now

- Amazing GOOP 160012 Automotive Adhesive Buy Now

- Blue Magic QuikSteel Steel Reinforced Epoxy Putty Buy Now

- Epoxy Glue – Clear 2 Part Metal Adhesive Buy Now

- Loctite Epoxy Weld Bonding Compound Buy Now

- Devcon 52345 Plastic Steel Epoxy Buy Now

How We Selected The 12 Best Glues for Metal in 2024

In our quest to identify the best glues for metal, we undertook a comprehensive evaluation process that balanced practicality, performance, and user preferences. Understanding the diverse needs of both professional tradespeople and DIY enthusiasts was crucial in shaping our selection criteria. Our focus was not just on the immediate adhesive strength but also on how well these products performed under various conditions over time.

Four key factors formed the cornerstone of our selection process:

- Bond Strength and Durability: The primary requirement for metal glue is its ability to form a strong, lasting bond. We looked for products that offer high tensile strength and can withstand stress, temperature variations, and environmental factors.

- Versatility in Application: Considering the wide range of metals and their differing properties, we favored glues that are effective across various metal types. This versatility also extends to compatibility with other materials, making the glue useful for multi-material projects.

- Ease of Use and Curing Time: The user experience is vital. We selected products that are straightforward to apply and have reasonable curing times to suit both quick fixes and projects that allow for longer setting periods.

- User Reviews and Brand Trustworthiness: We weighed user feedback heavily, as real-world experiences often highlight aspects not evident in lab tests. Additionally, we considered the reputation of the manufacturers for consistent quality and reliability in their products.

Tips for Choosing the Best Glue for Metal

Nowadays, a wide range of products claim to be capable of a bonding metal. The claims may be mostly accurate, but there are significant differences that will determine which metal glue is ideal for a certain project. Understanding how each operates with various sorts of materials and their suitability for various situations is helpful.

Bonding Process and Drying Time

The bonding and drying times vary depending on the type of metal glue used. While there are differences amongst products, the majority share the following traits, which can be divided into the following groups. The manufacturer’s instructions should be double-checked for any changes to the process or drying and curing times. The maker might also advise wearing gloves or other safety equipment.

- Epoxy: These adhesives are flexible, although epoxy can be difficult to prepare a surface for. Any taint will make the relationship more brittle. If at all possible, it is typically advised to use coarse abrasives to grit metal surfaces. Both of the surfaces that will be bonded should be coated with epoxy. Between 5 and 30 minutes are needed for initial drying, and between 4 and 24 hours are needed for a complete cure.

- Polyurethane: These adhesives are one-part polyurethanes, which are typically more forgiving than epoxy. However, application varies and caution with preparation is always advised. Some are put on just one surface, while others are put on both. Initial drying often takes a few hours, but some construction adhesives can take up to two weeks to fully cure, even though some can cure completely in just 24 hours.

- Cyanoacrylate: Superglues are frequently thought to operate by just putting a small amount of adhesive on an object and holding it together for a few seconds, but they require a dry, clean surface in order to function. While all work relatively quickly and are only sprayed to one surface, drying times vary greatly. Drying might take anything from 2 or 3 seconds to 5 minutes, depending on the substance.

Resistance to Pressure, Chemicals, and Elements

Tensile strength, often known as adhesive bond strength, is occasionally employed as a measure of how well a specific glue operates. It represents the amount of pressure needed to break the bond and is expressed in pounds per square inch (psi). On some occasions, figures of over 5,000 psi have been cited, which is astonishing. Manufacturers are permitted to employ their measuring systems since there are no established tests. Even though these goods unquestionably deliver outstanding performance, it is hard to directly compare them without an outside audit.

Which product is best will also depend on environmental factors. Epoxies often resist water, thrive in challenging environments, and are unaffected by most store and household oils and chemicals. Polyurethanes, in particular construction adhesives, share the same characteristics. These may have temperature ranges ranging from minus zero to several hundred degrees Fahrenheit and may survive the sun’s damaging UV radiation. But it’s crucial to avoid making generalizations. Before making a purchase, it is important to check the specific resistance of each product.

Ease of Use

The simplicity of usage of different metal glues is another distinction. Some need to be combined, while others need special equipment to apply, and the majority need some initial setting time before they fully cure.

- Epoxy: Epoxy glue for metal is a two-part product that must be combined before use, as was already described. It is crucial to pay attention to the product’s “open” or working period, especially with rapid set versions, as it begins to cure as soon as it is mixed. It will start to solidify and get thicker and harder to work with after a short while. Typically, clamping is advised during the initial drying phase.

- Polyurethane: These are one-part adhesives that are frequently provided in bottles or as cartridges for caulking guns. They are comparatively forgiving in terms of open time and simple to disseminate. Some do have strong “grabs,” making them challenging to separate if out of alignment. After about ten minutes, they begin to stiffen. On occasion, it’s suggested to lightly mist surfaces with water to start the reaction. Good clamping is essential since polyurethanes expand. Any glue that squeezes out of joints can be removed more quickly with a moist cloth. Once fully hardened, the bond can be chiseled, filed, or sanded.

- Cyanoacrylate: When using cyanoacrylates, caution is required. Liquid versions are simple to spill, and incidents about parts being inappropriately bonded or even stuck to fingers are fairly uncommon. Gel forms of superglue are a little more forgiving. For use carefully, the tiny squeeze bottles provide excellent precision when adhering to small components.

It’s time to look at some samples now that you’ve had a chance to read about the various qualities of metal glues. The following products were chosen as some of the top glues for the metal in various categories based on the above-mentioned criteria. This list makes it simpler to choose the ideal glue for every given metal job. Here are what we think are the best glues for metal in 2024.

1. J-B Weld 8271 KwikWeld Professional Size

Specification

| Type | Two-part epoxy |

| Bond Strength | Very high |

| Setting/Curing Time | Sets in 6 minutes, cures in 4-6 hours |

| Special Features | Can be drilled, sanded, or painted after curing; resistant to most chemicals and temperatures |

General Descriptions

Many people agree that J-B Weld products are among the best adhesives for gluing metal to metal. They offer an alternative for glass, but their KwikWeld epoxy works well to adhere metal to wood, brick, masonry, ceramics, and fiberglass.

Both its 6-minute setting time and its 4 to 6-hour cure period are quicker than that of most epoxies. Once fully cured, it becomes waterproof and is sandable, primed, and paintable. It has a class-leading 3,127 psi of tensile strength and can endure temperatures as high as 230 degrees Fahrenheit.

For a successful bond, proper surface preparation is crucial as it is with all epoxies. The maker advises wearing gloves, eye protection, and a well-ventilated environment when using the product.

Product Specs

- Type: Epoxy

- Setting and curing times: 6 minutes to 6 hours

- Color when dry: Gray, but can be primed and painted

2. 3M Marine Adhesive Sealant Fast Cure

Specification

| Type | Polyurethane adhesive/sealant |

| Bond Strength | High |

| Setting/Curing Time | Sets in seconds |

| Special Features | Gel formula, no-drip, impact resistant |

General Descriptions

This is a quick-curing variation of a well-known 3M marine glue and sealer. Two surfaces are permanently sealed and bonded together as a result of the production of a robust and flexible polyurethane seal. Wood, fiberglass, metal, and a lot more materials all work well with it. Additionally, it performs admirably underwater and on boat interiors.

It can also be utilized in numerous other locations where sunshine is not available. Instead of the usual average of five to seven days, it usually heals in forty-eight hours. Other than that, it is essentially the same as the adhesive sealant used by boat professionals for more than 50 years, which is the industry standard. You don’t need to mix it; you can use it straight from the jar.

The resulting adhesive sealant is ideal for joints because it offers a strong, impermeable seal while remaining flexible. To avoid cracking, it is intended to lessen the stress brought on by shock and vibration. It is resistant to seawater as well as wind, weather, and harsh long-term temperatures. Regardless of where you use it, it will give you years of worry-free use.

3. Loctite Super Glue Ultra Gel Control

Specification

| Type | Cyanoacrylate (gel formula) |

| Bond Strength | High |

| Setting/Curing Time | Sets in seconds |

| Special Features | Gel formula, no-drip, impact resistant |

General Descriptions

One of the most well-known cyanoacrylate brands is Loctite (super glue). The company’s Super Glue Ultra Gel is much thicker than its liquids, which makes it simpler to use and hence less wasteful. As with all cyanoacrylates, bonding occurs very quickly and little finger pressure is needed.

Metal can be attached to rubber, paper, ceramics, plastic, and wood with Loctite Super Glue Ultra Gel. It is impact and vibration-resistant since it still has some flex. Although Loctite doesn’t give specifics, it claims that it can endure temperature fluctuations.

Although the innovative container does a fantastic job of controlling the flow, it gives the appearance that there is more glue than there actually is. The tube must be promptly closed after usage otherwise it will quickly start to dry out.

Product Specs

- Type: Cyanoacrylate

- Setting and curing times: 30 seconds to 5 minutes

- Color when dry: Clear

4. Aleene’s Jewelry & Metal Glue

Specification

| Type | Specialized metal adhesive |

| Bond Strength | Moderate to high |

| Setting/Curing Time | Sets in minutes, fully cures in 24 hours |

| Special Features | Designed for jewelry and metal, dries clear |

General Descriptions

Aleene’s Jewelry & Metal Glue adheres to a wide variety of materials, including ceramics, metal, leather, jewelry, rubber, mirrors, wires, and gemstones. The fast-bonding nature of this glue stops the gel from running when it is applied. It becomes clear as it dries and stays robust and durable. Three tubes, each containing 0.3 fluid ounces, are included with this item.

Although it was mainly created with jewels in mind, this glue is generally effective with metal. There are several applications for it, but the producer is now concentrating on jewelry. The ability to connect metal to other metals and other things, however, is intended. If the task is done properly, the glue itself appears to disappear because it dries cleanly.

5. Gorilla Original Glue

Specification

| Type | Polyurethane adhesive |

| Bond Strength | Very high |

| Setting/Curing Time | 10-15 minutes clamp time, 24 hours to cure |

| Special Features | Expands while curing, water-activated |

General Descriptions

One of the earliest companies to offer polyurethane glue was the Gorilla brand, which has been around for more than a century. It offers high-strength bonding of metal, wood, most polymers, concrete, masonry, ceramics, stone, glass, and foam. It is a very versatile substance. When diverse materials need to be cemented together, it is especially beneficial.

The manufacturer claims that this adhesive has good temperature resistance, however, it doesn’t provide a range. However, because it is completely waterproof, freeze-proof, and immune to the sun’s harmful UV rays, it may be used both inside and outside.

As a gap filler, the foaming action works fantastically. However, the expansion may cause objects to separate, thus clamping is highly advised. This can be challenging with small goods, but paper tape or packing tape usually works well.

Product Specs

- Type: Polyurethane

- Setting and curing times: 2 hours to 24 hours

- Color when dry: Brown, but can be stained or painted

6. Liquid Nails Fuze It Max

Specification

| Type | Hybrid adhesive technology |

| Bond Strength | High |

| Setting/Curing Time | Sets in minutes, cures in 24 hours |

| Special Features | All surface, all weather, low VOC |

General Descriptions

Fuze It Max by Liquid Nails is a remarkably adaptable adhesive that can bond metal to almost any surface, including uncommon ones like drywall, marble, bathroom tiles, concrete, and PVC. It can be used in rain or shine and at temperatures between 0 and 140 degrees Fahrenheit.

When possible, it is desirable to do a test assembly before application because of its powerful grip. It might be challenging to undo mistakes. It simply takes ten minutes to set up initially. It can endure temperatures between -40 and 300 degrees Fahrenheit after being properly cured. The formula has been given the independent Greenguard Gold certificate for low emissions and has minimal odor and low VOCs (volatile organic compounds).

Product Specs

- Type: Polyurethane

- Setting and curing times: 10 minutes to 24 hours

- Color when dry: Brown, but can be painted

7. Permatex PermaPoxy 4 Minute Multi-Metal Epoxy

Specification

| Type | Two-part epoxy |

| Bond Strength | High |

| Setting/Curing Time | Sets in 4 minutes, cures in 24 hours |

| Special Features | Versatile metal bonding, no clamping needed |

General Descriptions

This two-part adhesive is a multi-metal epoxy that is simple to apply and may also be used as a filler; thanks to its adaptability, brazing, and welding are rarely necessary. It produces a dark gray tone and sets in about four minutes without the need for clamping. Because it won’t shrink as it dries, it can also fill in gaps.

This glue can be threaded, drilled, filed, and other operations after it has dried. Water and other solvents do not affect it. A temperature range of -60 to 300 degrees Fahrenheit can be handled by it with ease. Approximately 4500 pounds per square inch is its maximum strength. This makes it ideal for complicated tasks with numerous components. It is useful for sealing welded seams and filling metal cracks.

Because of its many applications, it is a great glue to use if you are not proficient at welding. It is very effective at bonding not only metal to metal but also metal to other ridge materials.

8. Amazing GOOP 160012 Automotive Adhesive

Specification

| Type | Solvent-based adhesive |

| Bond Strength | High |

| Setting/Curing Time | Sets in minutes, cures in 24-72 hours |

| Special Features | Resistant to heat and chemicals, flexible |

General Descriptions

Amazing GOOP glue offers a superb connection between metal, vinyl, rubber, plastic, and glass, making it ideal for vehicle repair and restoration. Once cured, it retains its flexibility, making it suitable for repairing hoses and the roofs of convertibles. Additionally, it can shield battery connections and insulate electrical cables. It is impervious to rain, sunlight’s UV rays, and heat up to 150 degrees Fahrenheit.

Additionally, it works well as glue for ordinary DIY and plumbing projects. Brick, PVC, stone, leather, and ceramics can all be joined with it. However, it melts Styrofoam and does not work on polyethylene or polypropylene.

It does emit an unpleasant vapor that might aggravate the respiratory and ocular systems. It should never be used close to an open flame because it is also combustible.

Product Specs

- Type: Silicon copolymer (similar to polyurethane)

- Setting and curing times: 45 minutes to 72 hours

- Color when dry: Clear

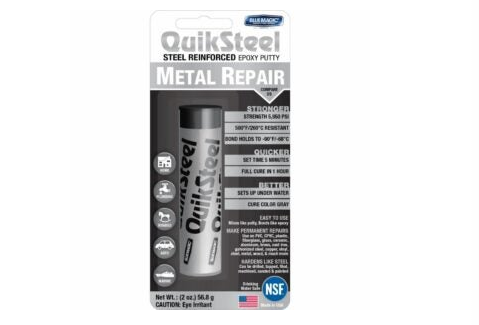

9. Blue Magic QuikSteel Steel Reinforced Epoxy Putty

Specification

| Type | Epoxy putty (steel reinforced) |

| Bond Strength | High |

| Setting/Curing Time | Sets in 5 minutes, fully cures in 1 hour |

| Special Features | Can be drilled, filed, tapped, and painted; withstands high temperatures |

General Descriptions

A two-part material called QuickSteel epoxy putty is mixed by hand before being molded into or around metal parts to join them. One of the very few adhesives that will adhere to cast iron is this one. It may be utilized in temperatures ranging from -90 to 500 degrees Fahrenheit and, once hardened, has a tensile strength of 5,950 psi. It can also be submerged in water. It can also be painted, machined, filed, sanded, and drilled.

It can be used to fix wood, ceramics, glass, fiberglass, PVC, and the majority of plastics in addition to fixing bicycles, metal furniture, appliances, and machinery. The unbiased NSF testing company gave it a “safe” rating for drinking water.

It must first be removed from painted or chrome-plated surfaces because it performs best on bare metal and fails on these surfaces. It has no elasticity and occasionally breaks when subjected to strong or repetitive impacts.

Product Specs

- Type: Epoxy putty

- Setting and curing times: 6 minutes to 1 hour

- Color when dry: Gray, but can be painted

10. Epoxy Glue – Clear 2 Part Metal Adhesive

Specification

| Type | Two-part epoxy |

| Bond Strength | High |

| Setting/Curing Time | Sets in 5-10 minutes, cures in 24 hours |

| Special Features | Clear finish, suitable for various materials including metal |

General Descriptions

Epoxy Glue – Clear 2 Part Metal Adhesive for bonding metal to other materials, including porcelain and ceramic. This adhesive gives up a huge variety of possibilities for your DIY projects and also works great as glue for more commonplace tasks because it can be applied to so many various surfaces.

This welding adhesive was created by mixing glue with powder, which results in a considerably stronger bond than glue used alone. Additionally, there are four alternative ways to apply the glue. This guarantees the best possible applicability in every circumstance. No two metal bonding situations are the same, for instance, you can be working with several metals that have peculiar or problematic forms. The use of an adhesive with lots of flexibility is beneficial as a result. This versatility is made possible by the four different ways this adhesive can be applied.

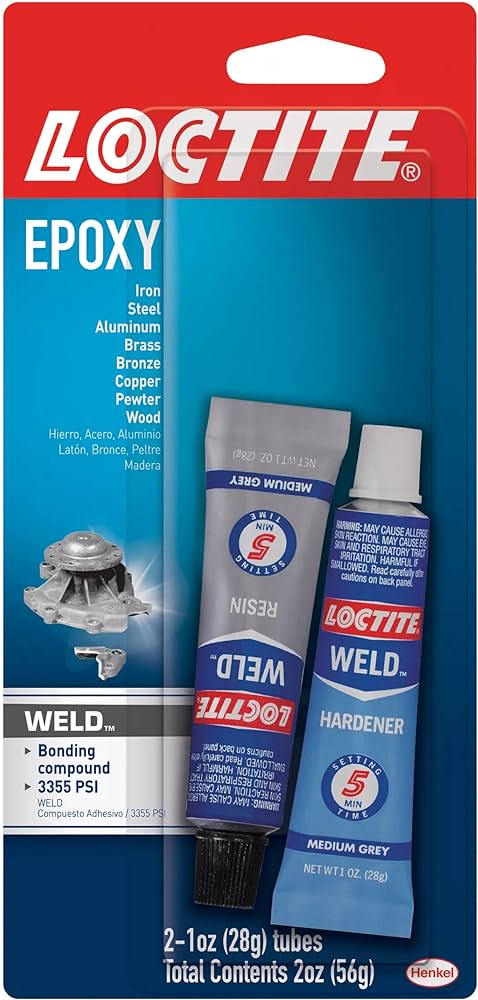

11. Loctite Epoxy Weld Bonding Compound

Specification

| Type | Two-part epoxy |

| Bond Strength | High (can vary based on the metals used) |

| Setting/Curing Time | Sets in 6 minutes, fully cures in 4-6 hours |

| Special Features | Can be sanded, drilled, and painted; chemical and heat resistant; works on various metals |

General Descriptions

Loctite Epoxy Weld Bonding Compound is a specialized adhesive formulated for high-strength bonding of metals. It’s part of the Loctite family of adhesives, known for their reliability and strength. This two-part epoxy mimics the properties of welded joints, offering a robust and durable bond. It’s designed to work on a wide range of metals, including iron, steel, aluminum, brass, bronze, and copper. The product is often used in both DIY and professional settings, ideal for repair jobs, filling gaps in metal parts, and fabricating metal components. Its chemical resistance and ability to withstand extreme conditions make it a go-to choice for automotive, marine, and household metal repairs.

Loctite Epoxy Weld sets quickly and can be shaped, filed, sanded, and drilled after curing, offering versatility and ease of use. Its high-tensile strength ensures a long-lasting bond, capable of withstanding heavy loads and harsh environments.

12. Devcon 52345 Plastic Steel Epoxy

Specification

| Type | Two-part, steel-filled epoxy |

| Bond Strength | Very high |

| Setting/Curing Time | Sets in 30 minutes, fully cures in 16-24 hours |

| Special Features | Can be machined, drilled, or painted after curing; chemical and temperature resistant |

General Descriptions

Devcon 52345 Plastic Steel Epoxy is a high-performance adhesive designed specifically for bonding and repairing a variety of metal surfaces. Known for its exceptional strength and durability, this two-part epoxy is infused with steel, making it ideal for heavy-duty repairs where a robust and long-lasting bond is essential. It’s frequently used in industrial applications, automotive repairs, and home DIY projects, especially where metal parts are subject to stress and high loads. The formulation is tailored to offer superior adhesion to metals, filling gaps and creating a bond that mimics the strength and properties of steel.

The versatility of Devcon Plastic Steel Epoxy extends beyond just bonding; it can also be used for patching up holes, cracks, and worn surfaces in metal parts. Its steel-reinforced nature ensures that repairs are not only strong but also durable against physical impacts and environmental factors.

FAQs about Glues for Metal

1. What Is the Best Glue to Use on Metal?

Epoxy glue is the ideal adhesive to use when attaching metal to metal because it is made expressly for this usage. A resin and a hardener, the two components used to make epoxy glue, work together to create a remarkably powerful adhesive.

Epoxy glues frequently come with dispensers that make it easier to combine the right amount of resin with hardener, which is necessary for the epoxy to establish a solid bond. If you want to use the glue as effectively as possible after mixing the resin and hardener, you must act swiftly. This also implies that you must apply the glue using a steady tool. It’s also crucial to make sure the glue doesn’t get in contact with your skin. The surfaces being cemented together should be clamped together once the epoxy glue has been applied.

2. How Long Does It Take for A Glue for Metal to Dry?

Dry time varies by kind. Cyanoacrylates offer a temporary bind in a matter of seconds, but it takes them longer to fully cure. Other goods can take anything between 30 minutes and 24 hours. Never assume anything. Always pay close attention to the manufacturer’s instructions.

3. What Should We Consider Before Choosing a Metal Adhesive?

You’ll also need to be aware of the qualities of the surfaces you’re seeking to join when thinking about employing a metal adhesive.

4. What Are the Qualities of the Surfaces You Want to Bond?

For instance, aluminum surfaces require ongoing oxidization. For proper adhesion, the roughness of various metal kinds must be smoothed off.

5. What Are the Size and Structural Properties of the Surface Being Joined?

This will affect the conditions of the bonding, the amount of glue used, and the amount of time the glue requires to set.

6. What Kind of Environment Will the Project Be Used In?

This includes the weight it must bear as well as environmental factors like temperature and humidity.

7. Do the Materials You Are Using Have Pre-Coated Surfaces?

If they do, you will need to use a different kind of glue as a result.

8. How Do We Glue Metal to Wood?

Many types of glue work well. Cyanoacrylates, two-part epoxies, and construction adhesives are all effective. The environment in which the glued components are employed must be taken into account. Think about whether the glue needs to be waterproof and able to withstand temperature changes.

9. How Do We Prepare the Surface for Bonding?

A light sanding with fine-grit sandpaper is beneficial before joining two metal surfaces. By making it simpler for the glue to attach to the metal surfaces, the minor roughness will help them bind together more effectively.

- Next, clean a towel that won’t leave any fibers on the metal and wipe the surface with acetone or methyl ethyl ketone. Even if you do not sand the surfaces, you still need to perform this wipe-down.

- Then, use a stronger degreaser to scrub away any remaining grease or oil from the surface. To swiftly remove any remaining degreaser, quickly wipe the surface with acetone or methyl ethyl ketone.

- The surfaces must lastly have time to dry before the adhesive is applied.

- You are then prepared to use the adhesive. The work you do before working with metal is just as vital as the work you perform after. Therefore, you mustn’t neglect this step because doing so could have an impact on the outcome.

Answering all these questions is important to the success of your project. Don’t forget to leave a comment with your ideas. Additionally, if you have any questions, you may contact Linquip’s Experts.

Download The 12 Best Glues for Metal in 2024 PDF

You can download this article as a PDF so that you can access it whenever you like.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- The 7 Best Belt Sander

- The 8 Best Nail Gun for Framing

- The 10 Best Staple Guns for Upholstery + Buying Guide

- The 9 Best PLA Filaments

- The 10 Best Inspection Cameras + Buying Advice

- The 10 Best Wire Tracers + Purchase Factors

- The 9 Best CO2 Monitor

- The 8 Best Cordless Drills + Buying Guide

- The 8 Best Paint Sprayers + Buying Guide

- The 10 Best Conduit Bender

- The 10 Best Angle Grinders

- The 10 Best Welding Machines + Buying Guide

- The 6 Best Leaf Blowers + Buying Guide & PDF

- The 10 Best Snow Blowers + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 8 Best Attic Ladders + Buying Guide & PDF

- The 10 Best Electric Space Heater + Buying Guide

- The 9 Best Cordless Impact Wrenches

- The 7 Best Portable Band Saws + Tips for Choosing

- The 10 Best Circular Saws in the USA

- The 10 Best Hammers

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Pressure Washers

- The 8 Best Rust Converter (Review Guide)

- 8 Best Soldering Iron for Electronics & The Like + Buying Guide

- The 10 Best Fertilizer Spreader

- 10 Best Steel Toe Boots for Women (Clear Guide)

- The 4 Best Ceramic Coatings

- The 9 Best Commercial Patio Heaters + Buying Guide

- The 8 Best Soldering Irons + Buying Guide

- The 10 Best Drywall Anchors + Buying Guide

- The 10 Best Box Cutter/Utility Knife Options

- The 7 Best Industrial Fan + Buying Guide

- The 6 Best Industrial Vacuum Cleaners + Buying Guide

- The 7 Best Dust Extractor + Guide to Pick Dust Extractor

- The 10 Best Conduit Bender

- The 10 Best Digital Calipers

- The 6 Best PETG Filament + Tips For Choosing

- The 10 Best Staple Guns + Buying Guide

- The 10 Best Wire Crimping Tool + Buying Guide

- 15 Types of Glue Guns With Characteristics and Usage

Outstanding Information

Thanks Ladders.

Thanks Ladders