What is Dynamic Pump & How Does it Works?

Dynamic pumps are divided into different categories. These pumps are most commonly used worldwide, and are designed to move fluid by transfer of kinetic energy from its rotor (impellers) to the fluid. These pumps are widely used, efficient and fairly cheap to make. They are usually great for high to medium flow, low to medium viscosity applications. Here you can find a list of dynamic pump subcategories. Feel free to browse our comprehensive list of dynamic pumps, dynamic pumps' manufacturers, and service providers, or if you feel overwhelmed, just contact us and our experts will help you on with every stage of your project. At Linquip, our goal is to help you select and purchase the best pump possible for your application, and we are here to help you on all stages of design, purchase, and maintenance.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteDynamic Pump Subcategories

Top Companies in Dynamic Pump

+84 Companies in Dynamic Pump

Top Devices in Dynamic Pump

Related RFQs

Centrifugal Pumps category

LNQ-23121064

overhung centrifugal pump

LNQ-23121021

Centrifugal Pumps category

LNQ-23101107

End suction pump

LNQ-23101104

Centrifugal Pump

LNQ-23101103

self-priming pump

LNQ-23101056

Centrifugal Pumps category

LNQ-23071043

Direct Drive Pump

LNQ-23051143

Top Dynamic Pump Experts

What Is Dynamic Pump?

The dynamic pump is a type of velocity pump in which kinetic energy is imparted to the fluid by increasing the velocity of the flow. The energy gain from this increase in flow is converted into potential energy (pressure) when the flow velocity is reduced just prior to or just as the flow leaves the pump into the discharge pipe. The First Law of Thermodynamics, or more precisely Bernoulli's principle, explains how kinetic energy is transformed into pressure. An example of dynamic pumps is an increase in fluid velocity or pressure using a centrifugal pump to add kinetic energy.

We have provided a complete list of the Dynamic Pump for Sale in Linquip. Also, a list of Dynamic Pump Suppliers and Companies as well as Dynamic Pump Manufacturing can be found in Linquip.

Working Principle of Dynamic Pump

Dynamic pumps continuously add energy to working fluids as the blades rotate. As the liquid moves through the pump diffuser, this rise in fluid energy increases the pressure energy. Two major principles govern the operation of dynamic pumps.

Axial Pump

Axial pumps are among the most popular types of dynamic pumps. Pumps of this type are used to pump incompressible liquids at high pressures, as well as to deliver high flow rates at short delivery heads. As a result, the axial pump transfers energy only through flow-related processes. As the liquid is pumped parallel to the shaft of the pump, the pump is called an axial pump. This type of pump allows water to enter radially and discharge axially.

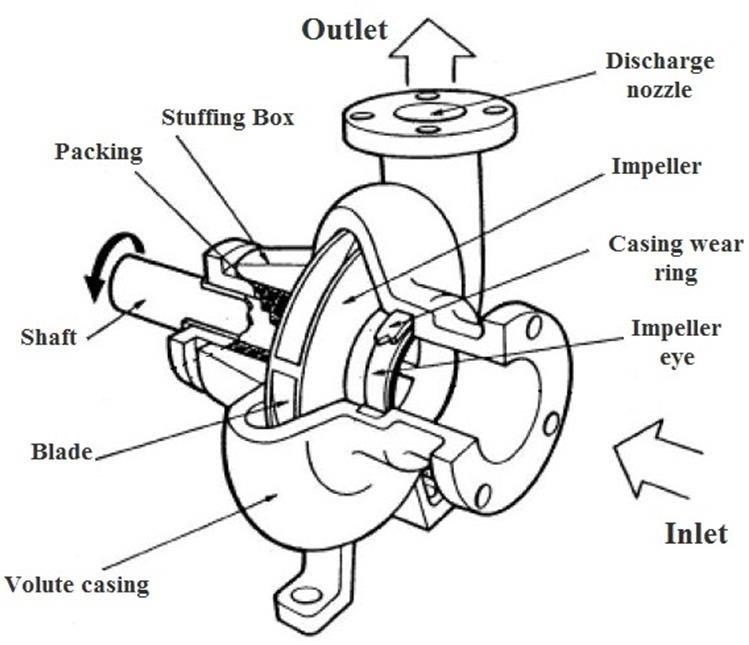

Centrifugal Pump

In hydraulics, centrifugal pumps are used as the most common pumping devices. Pumps of this type are used in a variety of applications. These types of dynamic pumps are inexpensive to manufacture, robust, and more efficient compared to positive displacement pumps.

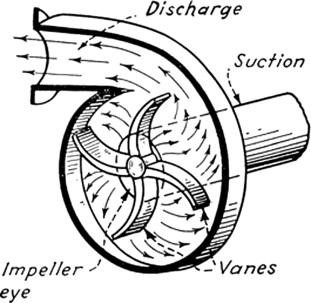

The centrifugal pump transfers energy from the motor to the liquid via a rotating impeller. In this arrangement, the water enters from the tank through the center of the impeller and exits at the top of the pump. This impeller is known as the pump's heart, Which has three types:

- Open impeller

- Semi-open impeller

- Enclosed impeller

The enclosed impeller provides the best efficiency. An enclosed impeller consists of a series of backward-curved vanes between two plates. The impeller stays submerged at all times. As soon as the impeller starts rotating, the fluid in which it lies will also rotate. Centrifugal forces are generated in fluid particles when the fluid rotates. The centrifugal force increases both the pressure and kinetic energy of the fluid.

In a centrifugal flow, the pressure decreases at the inlet nozzle (at the suction side) when centrifugal force occurs in the fluid particles. The pressure here is practically comparatively lower than that of the atmosphere. The low pressure will allow the fluid to be sucked from the storage. If the suction nozzle (the inlet one) is empty or filled with air, then the impeller will be damaged.

The difference between pressure generated at the suction side and the atmospheric pressure is very small to suck the fluid from the tank. The impeller is located inside the casing. Therefore, the fluid must be inside the casing. The casing should be designed so that maximum pressure will be generated at the exit.

Casing diameters are maximum at discharge nozzles and gradually decrease as we move inside. As a result, the volume of the fluid is greater at the discharge nozzle. Therefore, the velocity will decrease. Due to the inverse relationship between velocity and pressure, pressure increases as velocity decreases. In order to overcome the system's resistance, an increase in pressure is needed.

It is likely that bubbles will form inside the casing if the pressure at the inlet nozzle drops below the vapor pressure of the fluid. During this condition, the fluid starts to boil and form bubbles, which is very dangerous for the pump. As a result, the impeller will be damaged by those bubbles. The process is called cavitation. Increasing the inlet nozzle pressure (suction) requires decreasing the section head.

Each type of impeller has its own uses. A semi-open or an open impeller is used if the fluid is cloggy. However, the efficiency will decrease. Mechanically designing the pump can also be complicated. The shaft connects the impeller to the motor, which transfers the motor's rotary motion to the impeller. Since there is high pressure inside the casing, proper seals are required.

Function of Dynamic Pumps

Pumps of this type function based on the following characteristics:

- Continuous energy

- The process of converting energy added into kinetic energy (an increase in velocity)

- The process of converting increased velocity (kinetic energy) into an increase in pressure

There is a practical difference between dynamic and positive displacement pumps in how they operate when the valve is closed. Pumps that use positive displacement actually displace fluid, so closing a valve downstream of a positive displacement pump can cause a continuous build-up of pressure that can damage the pipeline or pump. In contrast, dynamic pumps can be run under closed valve conditions (for short periods).

Usage of Dynamic Pumps

In dynamic pumps, fluid velocity creates pumping power, moves fluid through the system, and creates the required pressure. In the industry, dynamic pumps are the most important type. For water supply, dynamic pumps are used. The low cost and small size of these pumps make them preferred over positive displacement pumps. Different types of dynamic pumps are used for different applications. Uses include water pumping, sewage pumping, agriculture, petroleum pumping, and petrochemical pumping.

In principle, centrifugal pumps are the most commonly used dynamic pumps around the world due to their robustness, simplicity, and cost-effectiveness. In centrifugal pumps, the output increases with increasing rotation speed. They are designed for fixed head applications.

Common Applications of Dynamic Pumps

Dynamic pumps are used in a wide range of industrial applications, including:

- Pumping crude oil is one of the most popular uses of these pumps.

- Also, they are used in the chemical industry.

- These pumps are also used commercially and in households.

- The food industry also uses these pumps.

- Fire protection is another industry that uses these pumps.

- Cellulose, petrochemicals, hydrocarbons, paint, and beverage production are among their uses.

FAQ about Dynamic Pumps

- What Is the Difference between Dynamic Pump and Positive Displacement Pump?

Dynamic pumps and positive displacement pumps are the two major types of pumps. The fluid flow in a dynamic pump is constant, but in a positive displacement pump, portions of the fluid are enclosed before being moved.

- What Is the Working Principle of Centrifugal Pump?

Centrifugal pumps belong to the Dynamic pump category. Centrifugal pumps work by using centrifugal force to transfer energy to fluid while rotating an impeller with several blades or vanes.