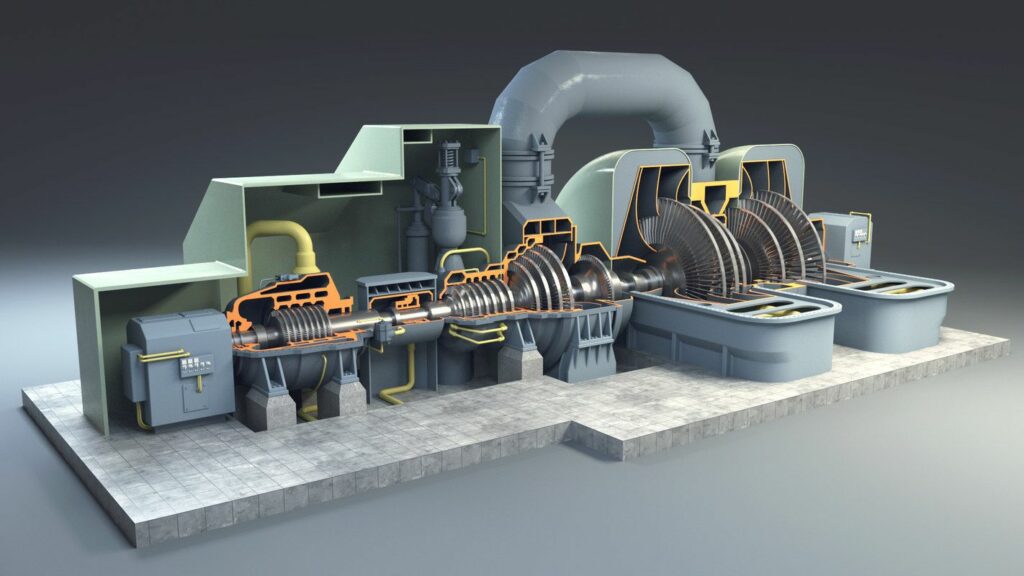

In this article, we are going to have a look at the types of Steam Turbine. All steam turbines are made up of the same components, but based on the arrangement of these components, there will be changes in the turbines that will lead to the formation of different types. In this article, we try to introduce you to these types and make you more familiar with the construction of different types of steam turbines.

A Steam Turbine is a mechanical mechanism that extracts thermal energy from forced steam and transforms it into mechanical energy. Understanding the many types of steam turbines is crucial while utilizing this product. Several Suppliers And Companies, as well as various manufacturers and distributors, provide various types of Steam Turbines, and there are several steam turbines for sale on Linquip.

Linquip’s website has a complete selection of Steam Turbine Services that will meet all of your needs. Linquip can connect you with a number of steam turbine service companies and experts who can help you. Linquip offers a team of Steam Turbine and Subject Matter Specialists who can help you test your equipment.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

What is Steam Turbine?

Steam turbine comes under the classification of a mechanical machine that isolates thermal energy form the forced steam and converts this into mechanical energy. As the turbine produces rotatory motion, it is most appropriate for the operation of electrical generators. The name itself indicates the device is driven by steam and when the vaporous stream flows across the turbine’s blades, then the steam cools and then expands thus delivering almost the energy that it has and this is the continual process.

In the following section, you will read about different types of steam turbines and their specifications.

Types of Steam Turbines

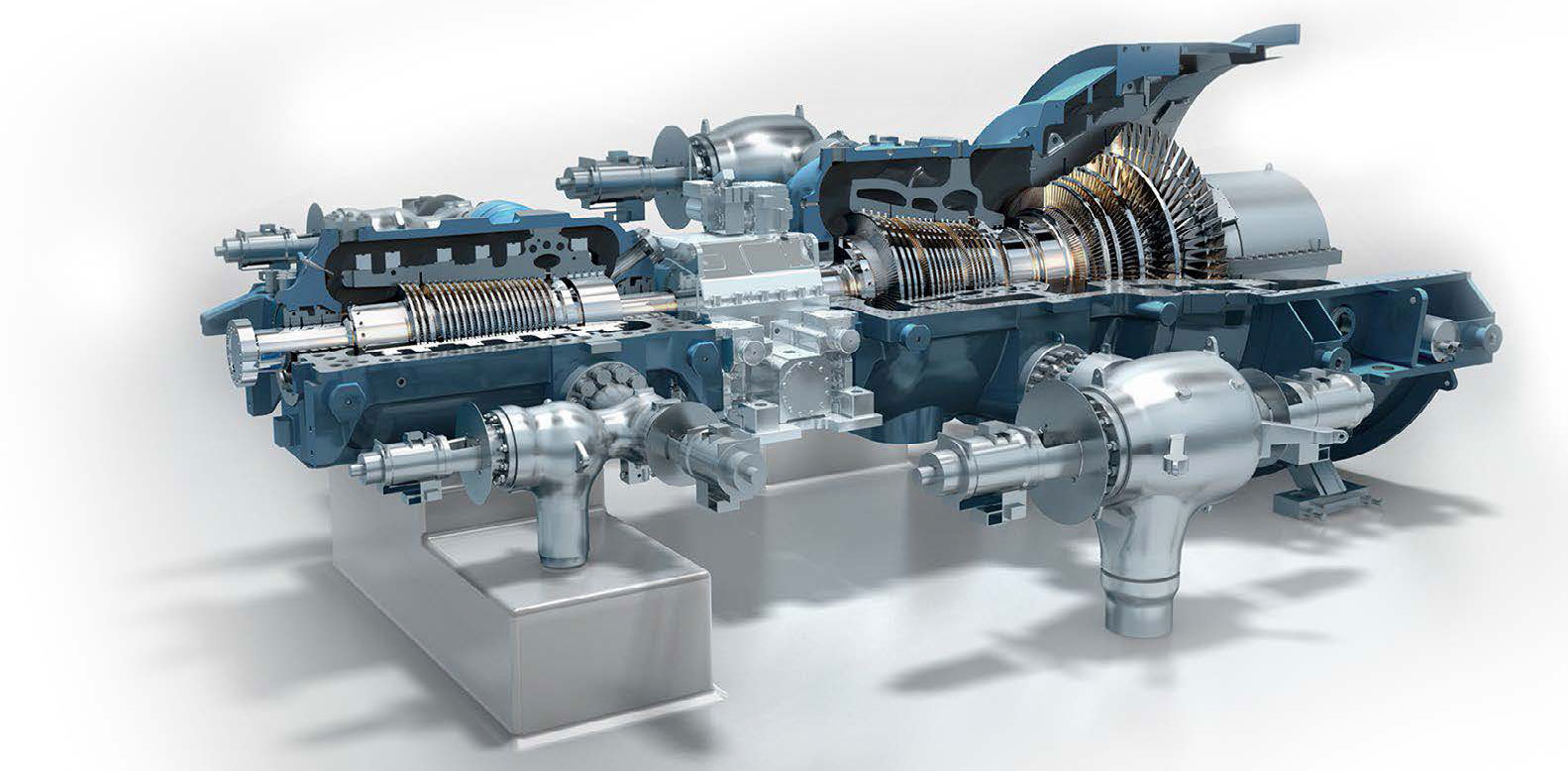

Steam turbines may be classified into different categories depending on their construction, working pressures, size, and many other elements. But there are two basic types of steam turbines which are called impulse and reaction turbines. There are other types of steam turbines that are actually derivatives of these two main types.

1. Impulse Turbine

In this type of turbine, the superheated steam is projected at high velocity from fixed nozzles in the casing. When the steam strikes the blades (sometimes called buckets), it causes the turbine shaft to rotate. The high pressure and intermediate pressure stages of a steam turbine are usually impulsed turbines. The entire pressure drops of steam take place in stationary nozzles only. Though the theoretical impulse blades have zero pressure drop in the moving blades, practically, for the flow to take place across the moving blades, there must be a small pressure drop across the moving blades also.

In impulse turbines, the steam expands through the nozzle, where most of the pressure potential energy is converted to kinetic energy. The high-velocity steam from fixed nozzles impacts the blades changes its direction, which in turn applies a force. The resulting impulse drives the blades forward, causing the rotor to turn. The main feature of these turbines is that the pressure drop per single stage can be quite large, allowing for large blades and a smaller number of stages. Except for low-power applications, turbine blades are arranged in multiple stages in series, called compounding, which greatly improves efficiency at low speeds.

Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. The rotor blades are usually designed like an impulse blade at the rot and like a reaction blade at the tip.

Since the Curtis stages reduce the pressure and temperature of the fluid to a moderate level significantly with a high proportion of work per stage. A usual arrangement is to provide on the high-pressure side one or more Curtis stages, followed by Rateau or reaction staging. In general, when friction is taken into account reaction stages the reaction stage is found to be the most efficient, followed by Rateau and Curtis in that order. Frictional losses are significant for Curti’s stages since these are proportional to steam velocity squared. The reason that frictional losses are less significant in the reaction stage lies in the fact that the steam expands continuously and therefore flow velocities are lower.

2. Reaction Turbine

In this type of steam turbine, the steam passes from fixed blades of the stator through the shaped rotor blades nozzles causing a reaction and rotating the turbine shaft. The low-pressure stage of a steam turbine is usually a reaction-type turbine. This steam having already expanded through the high and intermediate stages of the turbine is now of low pressure and temperature, ideally suited to a reaction turbine.

In reaction turbines, the steam expands through the fixed nozzle, where the pressure potential energy is converted to kinetic energy. The high-velocity steam from fixed nozzles impacts the blades (nozzles), changes their direction, and undergoes further expansion. The change in its direction and the steam acceleration applies a force. The resulting impulse drives the blades forward, causing the rotor to turn. There is no net change in steam velocity across the stage but with a decrease in both pressure and temperature, reflecting the work performed in the driving of the rotor. In this type of turbine, the pressure drops take place in a number of stages, because the pressure drop in a single stage is limited.

The main feature of this type of turbine is that in contrast to the impulse turbine, the pressure drop per stage is lower, so the blades become smaller, and the number of stages increases. On the other hand, reaction turbines are usually more efficient, i.e. they have higher “isentropic turbine efficiency”. The reaction turbine was invented by Sir Charles Parsons and is known as the Parsons turbine.

In the case of steam turbines, such as would be used for electricity generation, a reaction turbine would require approximately double the number of blade rows as an impulse turbine, for the same degree of thermal energy conversion. Whilst this makes the reaction turbine much longer and heavier, the overall efficiency of a reaction turbine is slightly higher than the equivalent impulse turbine for the same thermal energy conversion.

Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. The rotor blades are usually designed like an impulse blade at the rot and like a reaction blade at the tip.

You have to remember that although there only two types of steam turbine there are numerous mechanical arrangements of these, which include reheat steam turbines, cross compound steam turbines, single casing turbines, tandem steam turbines, condensing and exhaust steam turbines and, axial and radial flow steam turbines.

Other Types of Steam Turbines

As we said before, there are only two main types of turbine. But there are other types of steam turbines that are actually the derivatives of those two main steam turbines with different arrangements that make a new way of working principle. Let’s see what we have of steam turbines.

-

Condensing and Noncondensing Turbines

The first two types of Steam Turbine categorized by the new arrangement and with a new way of working principle are condensing and noncondensing. In devices of the first type, steam is condensed at below atmospheric pressure so as to gain the maximum amount of energy from it. In noncondensing turbines, steam leaves the turbine at above atmospheric pressure and is then used for heating or for other required processes before being returned as water to the boiler.

Compared to the fuel needed for simply converting water into steam which is actually saturated steam, relatively little additional fuel has to be expended to increase the steam generator exit pressure and, especially, the temperature in order to produce superheated steam, which then is employed to drive a turbine. Noncondensing turbines are therefore an economical means of generating power _cogeneration_ when substantial amounts of heating or process steam are already needed.

In condensing turbines, substantial quantities of cooling water are required to carry away the heat released during condensation. While noncondensing turbines exhaust steam at or above atmospheric pressure, condensing turbines can condense at pressures of 90 to 100 kilopascals below atmospheric pressure. This allows for a much larger expansion of the steam and a larger change in enthalpy, resulting in higher work output and greater efficiency. All central station plants, where efficiency is a prime consideration, employ condensing turbines.

-

Back-Pressure Steam Turbines

Another steam turbine type is a back-pressure steam turbine, which is the most suitable equipment for mechanical-drive applications, such as the drivers of compressors or pumps. The term backpressure refers to steam turbines that exhaust steam at above atmospheric pressures. The discharge pressure is usually established by the specific application of the steam in a plant. Lower pressures are frequently used in small and large low-pressure (LP) applications, such as heating systems, and higher pressures are often used when supplying steam to industrial processes.

Industrial processes often include a further expansion for other smaller mechanical drives, using small steam turbines for driving rotating equipment (for instance, lubrication oil pumps) that continuously runs for long periods. Significant mechanical power generation capability is sacrificed when steam is used at appreciable pressure rather than being expanded to vacuum in a condenser. Discharging steam into a steam distribution system at 10 Bar Gauge (barg) can sacrifice around half the power that could be generated when the inlet steam conditions are around 50 barg and 420°C, typical of small and medium steam turbines.

Between the mechanical power output of a condensing steam turbine and the power and steam combination of a back-pressure steam turbine, essentially any ratio of power-to-heat output can be supplied. Back-pressure steam turbines can have many different back pressures, further increasing the variability of the power-to-heat ratio.

-

Extraction Steam Turbine

A fourth steam turbine type with a change in working principle is extraction steam turbines. An extraction turbine has one or more openings in its casing for the extraction of a portion of the steam at some intermediate pressure. The extracted steam may be used for process purposes. The steam extraction pressure may or may not be automatically regulated depending on the steam turbine design.

Regulated extraction allows for better steam flow adjustments through the steam turbine to generate additional mechanical power depending on the operating scenarios. In some special steam turbines, several extraction points may be included, each at a different pressure corresponding to a different temperature at which heating service is needed in a plant.

What Are the Types of Steam?

Saturated Steam (Dry)

Pressure-Temperature Relationship of Water & Steam.

Supercritical Water.

Unsaturated Steam (Wet)

Superheated Steam.

Various States of Water.

Conclusion

The present article was an attempt to deliver all the essential information about the types of steam turbines. Steam turbines are the most important machines in the energy conversion field. Knowing the types of steam turbines, in addition to increasing your technical knowledge of this machine, will make you more familiar with the overall construction of the steam turbines and have a clear understanding of how it works.

If you have any experience or encounter with steam turbines and know more about their parts, we will be very glad to have your opinions in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Download Types of Steam turbines PDF

Read More In Linquip

- How Does a Steam Turbine Work? A Simple Descriptive Guide

- Steam Turbine Parts: A Comprehensive and understandable Introduction to All Components

- The Practical Guide To The Difference Between Gas Turbine and Steam Turbines

- Steam Turbine Efficiency: Complete Explanation

- Top 10 Steam Turbine Manufacturers in World (2022 Update)

- Top 10 Steam Turbine Manufacturers in USA in 2022

- Top Steam Turbine Manufacturers in India in 2022

- Types of Turbines: Classifications and Types

- Types of Propellers, Historical Development, and The Ways of Their Construction

- Impulse Turbine: Working Principle, Components, and Types

- Types of Wind Turbines: The Quick and Easy Intro

- Gas Turbine Types : Overview of Types and Profitable Applications