Service and Isolation Valve: Working Principle & Function

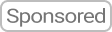

Service Valves can be found in non-return, isolation, and control roles, despite the fact that severe service control valves (SSCVs) have good industry agreement on what can be defined as severe service. The agreement and comprehension of SSIVs (Severe Service Isolation Valves) are much lower. An isolation valve is a device with a compression connector on both ends that is inserted in the supply line to an appliance. A service valve is a compression valve with a tap union fitting on one end and a compression end connected directly to the appliance on the other. A service valve and a tap connector are combined in the service valve. Isolation valves are squeezed on both ends. It can thus be employed in the middle of a pipe segment. Service valves have a compressed end and a threaded end, allowing them to be screwed onto a ball valve, tap, or other similar devices. An Isolation Valve is a fluid management device that stops the flow of process fluids in a pipeline, usually for maintenance or safety reasons. They can also be automated to modify the flow path in a continuous or batch operation.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Service and Isolation Valve

+2 Companies in Service and Isolation Valve

Top Devices in Service and Isolation Valve

Related RFQs

Service and Isolation Valve category

LNQ-23051240

What Is Isolation Valve?

In a fluid handling system, an isolation valve is a valve that obstructs the flow of process media to a particular location, generally for maintenance or safety reasons. As well as providing flow logic (choosing one flow path over another), isolation valves can also be used to connect external devices to the system. An isolation valve is so-called because of the function it is intended to perform in a system, not because of its type. Therefore, many different valve types can be categorized as isolation valves.

Imagine the valves under a typical household kitchen or bathroom sink to understand the concept of an isolation valve. Normally, these valves are left open so users can turn on or off the water directly from the spigot above the sink and do not have to get under the counter to turn the water on or off. Whenever the spigot needs to be replaced (i.e. when maintenance is required on the system), the isolation valves are closed to prevent water from flowing through the system.

There may even be a shared valve type between the isolation valve and the spigot in this system. However, due to their function, they are classified as the isolation valves and the control valves in the case of the spigot.

In Linquip, you can find isolation valve Companies and Manufacturers as well as expert Service Providers.

Components of an Isolation Valve

The components of isolation valves differ based on the type of valve being used. Gate valves, globe valves, ball valves, and butterfly valves are all suitable as isolation valves.

Globe valves are among the most popular linear movement valves in the marketplace today. They are available in various configurations to meet the demands of virtually any application. A valve with a horizontal inlet and outlet has fluid that must follow a changing path during operation; because of this, the fluid must move longitudinally to the obturator.

This arrangement offers the main advantage of allowing for rapid opening of the globe valve as the disc only requires moving a small distance from the seat to allow full flow. When the valve must be operated frequently, this can be an advantage.

However, due to the change of direction, the fluid is more likely to generate turbulence and increase resistance to flow. Because of this disadvantage, globe valves experience more pressure drop than gate valves.

The isolation valve, in this case, consists of these components as shown in the figure above:

- Valve seat

- Valve disc

- Body of valve

- Bonnet

- Stem seal

Due to their infrequent use and limited usage, isolation valves are often made of inferior quality globe valves. These cheaper styles do not have a stem and bonnet seal; instead, threading the stem directly into the body. Rubber washers and metal caps resemble gland nuts on the stem. Since they lack a stem seal, they could leak unless completely closed and installed in the right direction or completely open, making the disk compress the top washer against the stem.

Working Principle of an Isolation Valve

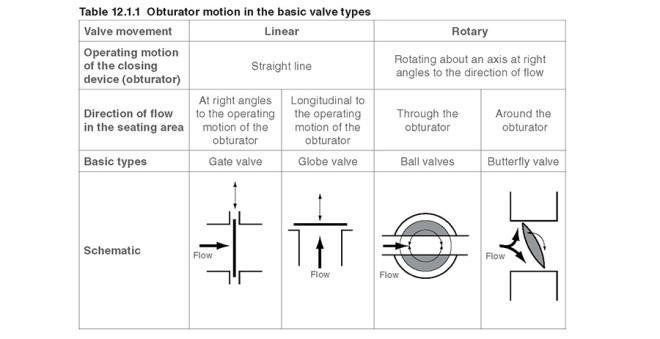

Isolation valves generally work according to one of two principles, depending on how the closure device (or obturator) operates:

Linear movement Valves

Obturators move in straight lines. An example of this is a gate valve, a globe valve, a diaphragm valve, and a pinch valve. Even though linear movement valves have a straight obturator movement, fluid flow can be perpendicular to that movement (for example, through gate valves) or in the same direction, for instance, through globe valves. With linear motion valves, tight shut-off is accomplished by tightening the obturator on the stem.

Rotary movement Valves

The obturator of a rotary isolation valve rotates about an axis perpendicular to the direction of flow. The most common rotary valves in steam applications are ball valves and butterfly valves.

The table below explains the working principle of linear and rotary movement isolation valves.

Function of an Isolation Valve

The isolation valves can be in either the open or closed position. Normally open valves connect pressure vessels, pumps, compressors, tanks, liquid level measurement devices, pressure sensors, and other components so fluids can flow between them or be connected to sensors. By controlling the closure of open valves, plant components may be isolated for testing or repairs and specific liquid flow paths can be enabled. When necessary, normally closed valves are utilized to connect fluids and parts to other systems.

The isolation valve must stop fluids from passing through. It is generally considered that ball valves, plug valves, and gate valves provide tight shut-off. A Globe valve and Butterfly valve may not be able to provide a tight shut-off, either because the plug and seat are worn out or because their design makes them ineffective for isolation.

Linquip offers a wide variety of Distributers, Experts, and Equipment for Sale of isolation valves.

Usage of Isolation Valves

An isolation valve isolates the actuation mechanism from the medium being moved. This type of valve is typically used when an on/off function is needed without having to gradually alter the flow rate.

You can use an isolation valve to isolate your leak if it is coming from a tap or toilet instead of shutting off the water to your entire property. The isolation valve is usually found directly under the toilet or directly underneath the tap.

Water isolation valves isolate faulty parts of the system from the rest and eliminate the need to make costly service calls. They allow future maintenance of individual fittings to be performed without affecting the rest of the household system. The result is lower energy costs (no hot water is wasted) and less excess water consumption.

Isolation valves are used for many general purposes, including:

- Diverting process media.

- Flow isolation to facilitate maintenance

- Flow isolation to allow the removal of equipment

- Flow isolation to allow the shut down of plant

Common Applications of Isolation Valves

A wide range of different applications require isolation valves that can be turned on and off as necessary; these include:

- Firewater control

- Pipeline safety systems

- The plumbing system for residential buildings (both water and gas)

- Chemical plant

- Oil production plant

- Oil and gas wells

- Nuclear reactors

There are many designs and types of isolation valves available to meet diverse applications and operational conditions.

Main Steam Isolation Valve

A main steam isolation valve is used to ensure a fast and tight shutdown of the main steam lines in a nuclear power plant. The valve used to isolate the steam supply from the turbine is usually motor powered or operated by air.

Firewater control Isolation Valve

At the firewater pump, manual isolation valves are provided to allow its removal without affecting the entire system. Flow performance tests can also be performed using them.

Pipeline Safety Control Isolation Valve

Pipelines have valves installed along their lengths that can be closed to stop the flow for maintenance, repairs, or for gas leak detection. The valves are quickly closed in case of a pipeline rupture or leak.

Subsea Isolation Valve

An emergency isolation valve is provided for subsea pipelines in offshore facilities when a risk analysis shows that the topside isolation may be considered vulnerable.

Process Isolation Valve

During an emergency, process isolation valves should be easily accessible so that hazardous materials cannot enter the facility. In addition, they may be used to prevent materials from leaving the facility in order to prevent downstream problems.

FAQ about Isolation Valve

- What is isolation valve used for?

Valve isolation valves separate the valve actuation mechanism from the medium being moved. In applications where simple on/off functions are required without the requirement for gradual modulation of flow, these valves are typically used.

- What types of valves are used for isolation?

An isolation valve can be a gate, ball, globe, butterfly, or diaphragm valve.

- What is isolation valve in plumbing?

By using isolation valves, water can be controlled from the mains to the water service pipe. Using one of these valves, one can repair a dripping tap without having to shut off the mains water.