Diaphragm Pump: Working Principles, Function & Diagram

An Industrial Diaphragm Pump (also known as a Membrane pump) is a type of industrial pump. It's a positive displacement pump that uses a rubber, thermoplastic, or Teflon diaphragm and corresponding valves (butterfly valves, flap valves, check valves, or any other type of shut-off valves) on each side of the diaphragm to pump a fluid. The diaphragm pump has a wide range of uses in a variety of sectors. Corrosive chemicals, volatile solvents, viscous, shear-sensitive meals, pharma goods, sticky fluids, unclean water, tiny particles, abrasive slurry, creams, gels, and oils are all pushed by these pumps. Diaphragm pumps have a number of features that make them excellent for use on spraying bars and air-blast sprayers in agriculture. The three primary advantages of a diaphragm pump over a centrifugal pump are excellent self-priming and head capacity. Dry running capacity is good.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Diaphragm pumps

+15 Companies in Diaphragm pumps

Top Devices in Diaphragm pumps

Related RFQs

Diaphragm Pump

LNQ-22111637

Diaphragm Pump

LNQ-22111369

Diaphragm Pump

LNQ-22041299

Diaphragm Pump

LNQ-21121110

What is a Diaphragm Pump?

A diaphragm pump (also recognized as a Membrane pump) is a type of industrial pump. It’s a positive displacement pump that pumps a fluid using the reciprocating action of a rubber, thermoplastic, or Teflon diaphragm and appropriate valves on either side of the diaphragm (butterfly valves, check valves, flap valves, or any other type of shut-off valves).

Various Types of Diaphragm Pumps

Diaphragm pumps come in three main types:

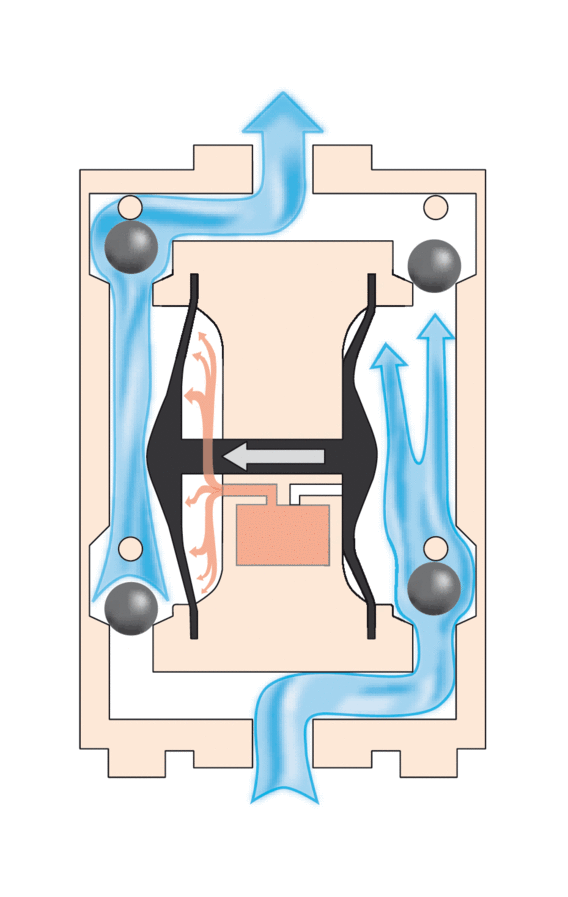

- Those in which one side of the diaphragm is immersed in the fluid to be pumped, while the other is immersed in the air or hydraulic fluid. When the diaphragm is stretched, the volume of the pump chamber rises and falls. A pair of non-return check valves prevent the fluid from flowing backward.

- Those that use a volumetric positive displacement diaphragm with an electro-mechanical prime mover, such as a crank or geared motor drive, or a purely mechanical prime mover, such as a lever or handle. The diaphragm is flexed using simple mechanical action, and one side of the diaphragm is accessible to the air.

- Those that use one or more unsealed diaphragms to pump fluid from both sides. The diaphragm(s) are flexed once more, changing the volume.

Working Principle of Diaphragm Pumps

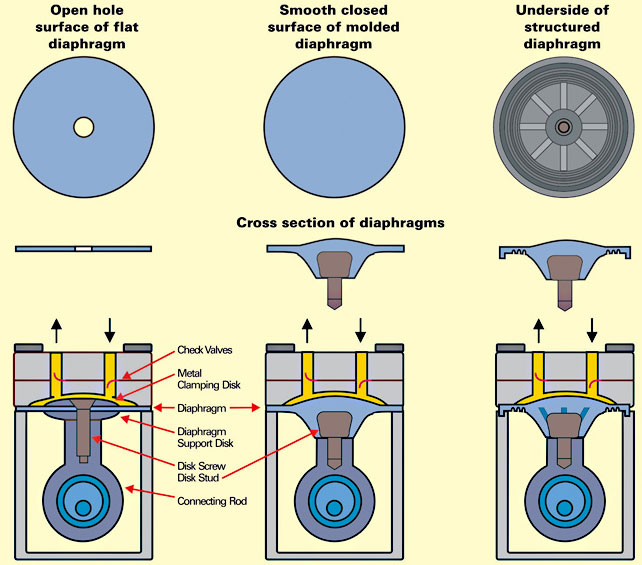

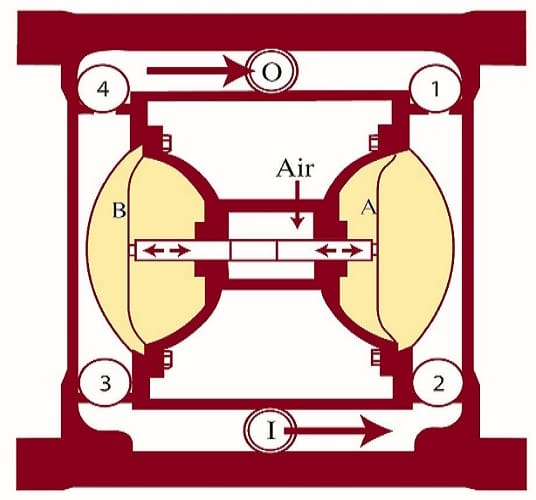

When the capacity of a chamber in either type of pump is enlarged (by pushing the diaphragm up), the pressure falls, and fluid is sucked into the chamber. The fluid brought in is driven out as the chamber pressure rises due to decreased volume (the diaphragm going down). Finally, the diaphragm rises, drawing fluid back into the chamber and completing the cycle. This movement is similar to that of an internal combustion engine's cylinder. Diaphragm Pumps create an airtight seal between the driving mechanism and the compression chamber, enabling the pump to transport, compress, and expel the medium without the use of lubricant.

An elastomeric diaphragm can be used as a versatile dynamic seal that overcomes many of the drawbacks of traditional sealing techniques. They don't leak, have little friction, and can be made with low-pressure sensitivity in mind. Diaphragms can seal through a wide variety of pressures and temperatures without lubrication or maintenance if the correct materials are used.

Characteristics of Diaphragm Pumps

Characteristics of diaphragm pumps are:

- They have good suction lift properties, and some are low-pressure pumps with modest flow rates; others, depending on the diaphragm's effective working diameter and stroke length, can deliver higher flow rates. They are capable of handling sludges and slurries with a high grit and solid content.

- Pump fluids are separated from potentially sensitive internal pump parts by the design of the pump.

- Internal pump parts are frequently suspended and isolated within the oil to extend the life of the pump.

- They are suitable for abrasive and corrosive solutions.

- It can withstand discharge pressures of up to 1,200 bar.

- They have excellent dry-running qualities.

- Artificial hearts can be made from them.

- They're utilized to construct air pumps for small fish tank filters.

- They can be as effective as up to 97%.

- They have a good ability to self-prime.

- They can handle liquids with a high viscosity. A viscosity correction chart can be used to avoid AOD pumps from becoming undersized.

You are also encouraged to visit the List of Pump Distributors in Linquip.

How to Choose a Diaphragm Pump?

Diaphragm pumps are one of the most well-known oil-free pump types. These are now employed in a variety of products to prevent oil vapor impurity issues that afflict many of today's stringent processes.

There are diaphragm pumps on the market without seal oil or lubricant in the pump head. That is, a vacuum can be formed in which all oil vapors are removed from the exhaust gases.

All diaphragm vacuum pumps, whether oil-free or not, have different operating qualities that make them ideal for one application but not for another. A diaphragm pump isn't any different.

It's not easy to match the type of pump to your application when it comes to pumping selection. However, the best way to choose a diaphragm vacuum pump is to evaluate the pump modes of operation with your application in terms of strength, attributes, and weaknesses.

Pumping huge amounts of materials at low pressure is easy using a diaphragm pump. Because they don't shift the piston in the cylinder, these pumps are often resistant to wear. Instead, one or more basic rubber diaphragms move left and right to convey material.

The steps for selecting a diaphragm pump are as follows:

1) Pump Volume Requirements: When selecting a diaphragm pump, it is critical to ensure that the pump you are considering works at 50% of its maximum capacity during everyday operation.

2) Type of displacement pump drive: The diaphragm of a diaphragm pump can be moved back and forth in a variety of ways to allow material to be pushed. Pneumatic or electrical drive pumps are the most common diaphragm pump driving alternatives. This drive is critical for the safe operation of the diaphragm pump, as well as the pump's operating position.

3) Pump material: Positive displacement pumps are made of a variety of materials. The pump seat and ball materials, as well as the pump body material, are the most acceptable material choices for available diaphragm pumps.

4) Pump performance curve for air-operated Diaphragm Pumps: Each diaphragm pump has a performance curve that offers a wealth of additional information. The amount of air (CFM) required by the diaphragm pump at various levels of operation, as well as the amount of material that can be supplied and moved at different levels of operation, are all covered by the diaphragm pump's performance curve.

You can find various Pump Suppliers and Companies in Linquip that can completely cover your requirements.

FAQs about Diaphragm Pumps

- What is a Diaphragm Pump Used For?

Diaphragm pumps are utilized in almost every notable industry. They're frequently employed to transport abrasive fluids like concrete, as well as chemicals and acids. They're also widespread in cars and airplanes. A membrane pump, air-driven double diaphragm pump (AODD), or pneumatic diaphragm pump is a type of diaphragm pump.

- What is the Difference Between a Diaphragm and a Centrifugal Pump?

While centrifugal pumps are a cost-effective and quick solution for high-volume pumping, they aren't always the ideal option. Pumps with a sanitary diaphragm are also preferable for handling goods that require high flow accuracy, shear sensitivity, or temperature control.

- What are The Advantages of a Diaphragm Pump?

They work with a wide range of fluids that contain a lot of solids. They also have the capacity to self-prime and run dry. They're also explosion-proof. This type of pump maintains a consistent pumping efficiency. They have a changeable flow rate and discharge pressure, and they don't become too hot. Finally, mechanical seals, couplings, and motors are not required.

- Can a Diaphragm Pump be Used to Pump Dirty Water?

Sticks, stones, mud, rubbish, and other material up to 2 in., or slightly larger than a golf ball, can be handled by diaphragm pumps. It can pump sludge, muddy water, and other heavy liquids with the ability to flow, making it useful in wastewater control applications.

- Can Diaphragm Pumps Pump Air?

The Air-Operated Diaphragm Pump is the most common form of a diaphragm pump. The power source for these pumps is compressed air. They also have two chambers, each with a diaphragm, an entrance check valve, and an outlet check valve.