What is Peripheral Pump & How Does it Works?

Peripheral pumps, or regenerative pumps, are centrifugal pumps that have impellers rotating inside a largely concentric casing channel with an inlet opening and an outlet. In the industrial sector, peripheral pumps are very helpful. In situations where small centrifugal pumps cannot meet a need or when a high head needs to be achieved while there is a low flow rate, peripheral pumps are particularly appropriate. There are many different kinds of industrial applications for peripheral pumps, including irrigation systems, pressurized water supply systems, and washing systems. In most cases, peripheral pumps are small, so they are suitable for use in small-scale solutions. A peripheral pump is useful in a variety of domestic situations, including water filtration, jetting (high-pressure cleaning), fluid transfer, water fountains, and water pressure boosting.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Peripheral Pump

Top Devices in Peripheral Pump

Pedrollo

Related RFQs

Gear pump

LNQ-22121335

What Is Peripheral Pump?

Water pumps come in many varieties, from centrifugal pumps to submersible pumps and well pumps. A peripheral pump is one of the most useful devices out there - in case you are not familiar with them and what they can do, here is a quick explanation.

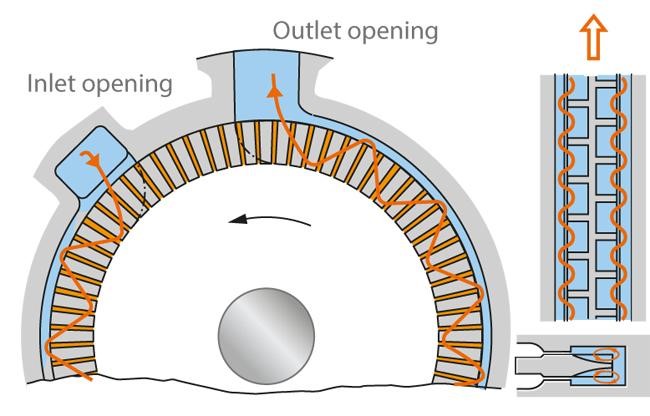

A peripheral pump has an impeller with many radial vanes on the outside edge and is a close-coupled centrifugal pump. The impeller rotates within a concentric channel of the casing with liquid flowing between the vanes and casing, which transfers large amounts of energy leading to an increase in pressure inside the pump. As pressure increases along the circumference of the casing, fluid moves from its inlet to its outlet. In the casing channel, the stripper is positioned between the outlet and the inlet to prevent a hydraulic short circuit between the high- and low-pressure sides.

A thin clearance between the impeller vanes and the pump casing means that any solids would stop the impeller, so they are generally designed for clean media. Peripheral pumps can be relatively small given the large increase in energy.

Applications that use peripheral pumps are typically those where a medium to the high-pressure transfer of low viscosity liquid is required, such as for hydrocyclone feed, filtration, fluid transfer across long distances, jetting, and display fountains.

We have provided a complete list of the Peripheral Pump for Sale in Linquip. Also, Peripheral Pump Suppliers and Companies and Peripheral Pump Manufacturing can be found in Linquip.

Working Principle of a Peripheral Pump

In essence, peripheral pumps are niche products that sit between displacement pumps and centrifugal pumps. In many applications in the industry, the medium is pumped in a peripheral channel, which is why we call it that. This pump works as a volume displacer by sucking the liquid through the suction flange. The liquid is then directed into an annular channel.

A peripheral impeller rotates within this channel, centrifugally transforming the liquid. Peripheral impellers are special impellers that have a large number of small radial vanes arranged around their perimeter. The blades in the impeller impart great kinetic energy onto the liquid as it exits the pump via the discharge flange after passing through the annular channel.

Peripheral pumps contain impellers with many small radial blades (with dual inputs) arranged along their peripheral area. Within the rotor, centrifugal forces create a circulation of the flow between the impeller and casing channel. A fluid and an impeller have essentially the same peripheral speeds, but the fluid in the casing channel has a significantly lower speed. Thus, the fluid flows spirally from the casing channel to the impeller, which occurs several times along the perimeter.

As more vortices form, more energy is transferred, and the produced pressure is higher. With a reduced flow, the number of spirals increases, so there is a greater transfer of energy and a higher amount of power absorbed in partial-load conditions.

Function of a Peripheral Pump

Peripheral pumps have higher head coefficients and steeper characteristic curves than side channel pumps. As the flow rate increases, peripheral pumps' input power decreases.

Multistage pumps are peripheral pumps that have multiple blade wheels arranged at the different diameter levels of the impeller. They have heads of up to 1,200 meters at speeds of 2,900 rpm. In applications requiring low flow rates, peripheral pumps may serve the same purpose as high-pressure geared pumps or even positive displacement pumps.

This pump is similar to a side channel pump. Unlike centrifugal pumps, these pumps have curves that do not flatten when the flow of liquid slows down. As the pump curves are straight lines, there is maximum head at low flows, and low height at peak flows.

Usage of Peripheral Pumps

Currently, these pumps are used for a variety of purposes. They have the added benefit of allowing gases to pass through without affecting the liquid flow or causing bearings to wear out due to dry running. In order to prevent abrasive materials from entering, they require very low suction heads and narrow columns. Peripheral pumps are excellent for pressure-sensitive systems because of their steep capacity/head curves.

With these features, peripheral pumps are suitable for a variety of small-scale applications. Some typical applications of peripheral pumps in the home include water filtration, fluid transfer, jetting (high-pressure cleaning), fountains, water pressure boosting, etc. Also, machinery applications include welders, chillers, and laundry equipment.

Common Applications of Peripheral Pumps

Peripheral pumps can be used in the following applications:

- To pump uncontaminated liquids, such as boiler feed pumps for small boilers

- Pressure boosting

- Car wash pumps

- Chemical industry

- Applications in which a low flow rate must be pumped at high pressure.

Advantages of Peripheral Pumps

Among the advantages of peripheral pumps are:

- Gas-entrained fluids can be handled without cavitation risk. Moreover, they have versions with the ability to self-prime up to 6m and handle any air ingress without trouble. When fitted with a foot valve, the standard models offer manometric suction lifts up to 8m.

- The flow rate is extremely low at high pressures, similar to gear pumps, without the use of gear boxes. Additionally, they are compact, and with low axial thrust, they have a long lifespan.

Features of Peripheral Pumps

Peripheral pumps are characterized by their ability to maintain very high pressure at low flow rates. A significant difference in pressure is produced between the pump's input and output because the impeller turns very close to the volute. That is the reason peripheral pumps are highly noisy, which is due to the way they operate. Peripheral pumps are, however, cheaper in comparison to centrifugal pumps and are also capable of self-priming.

Another characteristic of the peripheral pumps is that they can transport fluids with a high gas content, which sets them apart from other centrifugal pumps. A severe vapor bubble will not halt the flow or adversely affect the smooth operation of the pump.

FAQ about Peripheral Pumps

- What Is a Peripheral Pump?

Peripheral pumps can be viewed as being in the middle of the volumetric and centrifugal pump categories. The flow rate in the first category is unaffected by pressure, whereas the flow rate in the second category decreases with an increased head. In contrast, peripheral pumps follow a curve that falls between these two categories.

- What Are Peripheral Pumps Used for?

Peripheral pumps are particularly suitable for situations where small centrifugal pumps cannot fulfill a need or when a high head must be achieved even though a low flow rate exists. Water supply systems, irrigation systems, pressurization systems, and washing systems are just a few of the applications.