What is Electromagnetic Pump & How Does it Works?

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Electromagnetic Pump

Top Devices in Electromagnetic Pump

Related RFQs

Electromagnetic Pump category

LNQ-23071133

Electromagnetic Pump category

LNQ-22091501

Electromagnetic Pump category

LNQ-22021090

Electromagnetic Pump category

LNQ-22021002

CMI Novacast PG450 Electromagnetic Liquid Metal Pump

LNQ-21121042

A Brief Introduction to Electromagnetic Pump

An electromagnetic pump is a type of pump that uses magnetism to move liquid metal, molten salt, brine, or other electrically conductive liquids. During the flow of a liquid, a magnetic field is set at an angle to the liquid's direction, and a current is passed through it. In this way, the liquid is moved by an electromagnetic force.

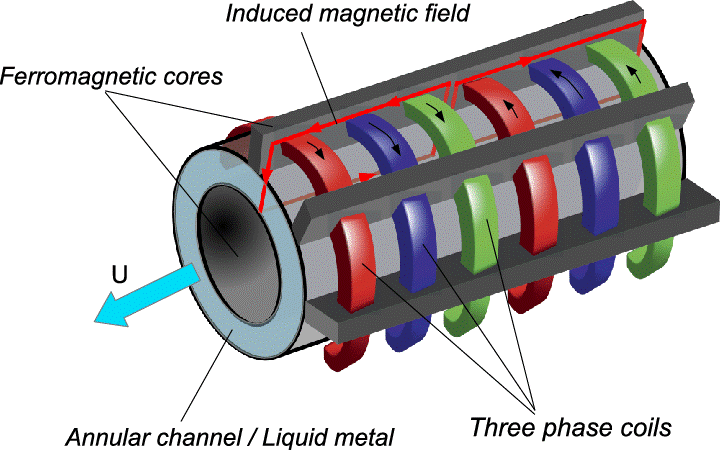

Generally, the liquid metal travels along an annular channel between two concentric cylinders. It is possible to place ferromagnetic cores on the inside of the channel in order to enhance the radial component of the magnetic field generated by a three-phase winding of electrical currents imposed on the outside of the channel.

Electromagnetic pumps can be classified into three categories: conduction pumps, induction pumps, and thermoelectric pumps. Conduction pumps conduct the current directly into the fluid through electrodes. There are two variants of it, A.C. (alternating current) and D.C. (direct current). During the operation of an Induction pump, the moving magnetic field induces a current within the conducting fluid. A Thermoelectric pump extracts power from the thermal energy contained in a heated liquid metal flow in order to power its current.

There are two main uses for electromagnetic pumps: cooling nuclear reactors and pouring and transporting metals in foundries at extremely high temperatures. The pumping of molten solder in a wave soldering machine, pumping liquid-metal cooling, and magnetohydrodynamic drives are among their applications.

Linquip has a selection of Electromagnetic Pumps for sale. Linquip also provides a list of Electromagnetic Pump Suppliers and Companies as well as Electromagnetic Pump Manufacturers.

Working Principle of Electromagnetic Pump

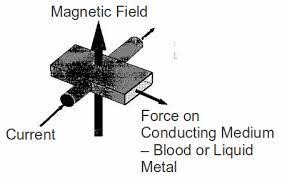

Once the current travels through a conductor, a magnetic field always exists alongside the electric field. If there is an external magnetic field, this current-carrying conductor experiences a force that is perpendicular to both the current direction and to the external magnetic field. Essentially, this is due to the fact the magnetic field produced by the conductor, as well as the external magnetic field where the conductor was kept, attempted to align with each other. This is the principle behind an electromagnetic pump.

With an electromagnetic pump, a liquid that is a good conductor of electricity is provided with current (I), which has a density of J. Two permanent magnets are used to create an external magnetic field. The magnetic field caused by the flow of current through liquid conductors is known as the reaction magnetic field. Both the current-carrying conductor field and the external magnetic field strive to align with each other, causing the fluid to move mechanically.

Transformer action induces an electric current in the EM pump. The primary coil of the transformer is connected to an alternating single-phase source of power. Transformer pole pieces are arranged so that they serve as carriers for magnetic flux.

Secondary windings in transformers are constructed with molten metal. A high number of turns causes the coil to intensify the electrical input current and produce a very high amperage of molten metal. A sectioned view of an electromagnet shows a C-shaped pole piece in conjunction with two excitation coils. In molten secondary turns, the opening of the C crosses the necked-down portion so that the magnetic field crossing the gap of the pole is perpendicular to the secondary current. As a result, the liquid metal moves through the pump due to this force.

In order to prevent any contact with the molten metal, the entire pump is encased in ceramic parts. The output can be controlled by changing the input power.

Applications of Electromagnetic Pump

EM pumps are passive pump systems and have been used for pumping liquid sodium in auxiliary cooling circuits, such as filling and draining metallic containers of such metallic liquids, and for purification circuits in sodium-cooled fast-breeder nuclear reactors namely Liquid Metal Fast Breeder Reactor (LMFBR).

Although these pumps have not been proven to be very effective at pumping liquid, they are commonly used in fast breeder reactors because of their high reliability and low maintenance due to the lack of moving parts, which is why they are considered passive pumps. As an additional benefit, EM Pumps can be augmented to pump impure sodium.

Despite centrifugal pumps being used for sodium pumping in the primary and secondary circuits of the reactor, electromagnetic pumps are preferred for the auxiliary circuits. This type of electromagnetic pump is inefficient and is therefore not suitable for use in the primary sodium circuits in fast reactors. Yet they can work even with impurities in sodium and have high reliability and almost maintenance-free operation, making them a perfect choice. They operate on the principle that any current-carrying conductor placed in a perpendicular magnetic field will exert an electromagnetic force.

Advantages of an Electromagnetic Pump

The use of an electromagnetic pump offers the following advantages:

- It does not have any moving parts or vibrations. Wear and tear is therefore not introduced to the system.

- Maintenance is less necessary, and the system works more efficiently.

- There is no likelihood of leaks or spills.

- It is cost-effective to install.

- There is no significant harmful impact on the environment.

Disadvantages of an Electromagnetic Pump

In addition to the advantages of electromagnetic pumps, there are also certain disadvantages.

- There is ohmic heating, which results in power loss.

- Since very few liquids are electrically conductive, electromagnetic pumps have limited applications.

- The Magneto-Hydrodynamics (MHD) instability that arises in the device poses a significant problem when developing induction pumps, especially annular linear induction pumps. A linear induction pump cannot be designed in a specific range of flow rates or be developed with high efficiency under certain flow rates and conditions of dropping pressures due to the manifestation of the instability.

Conclusion

We conclude that EM pumps are one of the best passive choices, as they do not require an external energy source to move parts to move liquids from one side to another, especially in a liquid metal environment where heat transfer is necessary. To accomplish this, they rely on the physics of electromagnetism phenomena.

FAQs about Electromagnetic Pump

- What Is Electromagnetic Force?

One of the four basic forces is electromagnetic force, and it can be applied in a variety of ways. All charged particles are subject to the electric force, regardless of whether they are moving or not. There is also a magnetic force acting on moving particles. It follows that every charged particle emits an electric field, whether it moves or not.

- What Are the Applications of Electromagnetic Pumps?

Liquid metals are handled by electromagnetic pumps at temperatures up to 1500°F. Due to the lack of moving parts and no seals, they are suitable for use with molten metals, particularly alkali metals such as NaK, sodium, and lithium.