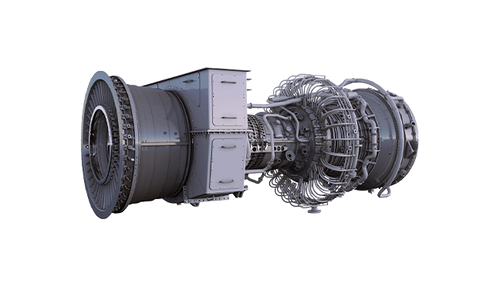

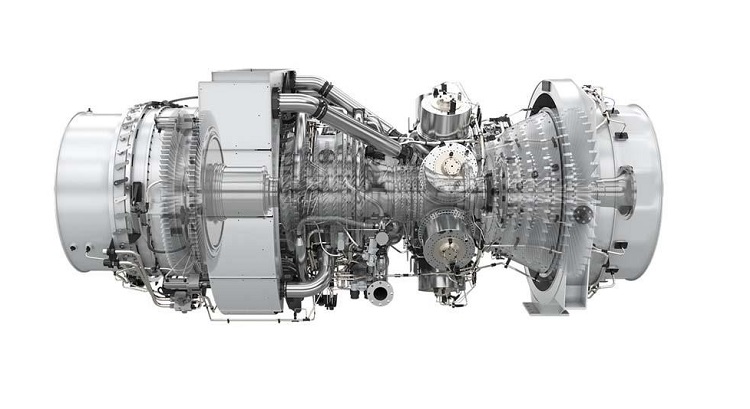

Aeroderivative Gas Turbine

The aero-derivative gas turbine is a lighter-weight version of a regular gas turbine. Despite industrial gas turbines, aero-derivative gas turbines are designed specifically for air use such as in airplanes. However, we also use aero-derivative gas turbines for land applications. Aeroderivative land turbines produce smaller power but are more compact, and run at higher efficiency and pressure ratios. The fuel source for the aero-derivative turbine is generally liquid fuel called aviation gasoline, often referred to as "avgas". Finding the right aero-derivative gas turbine is very important as it should completely meet your company’s needs otherwise you will lose a lot of budget and energy. Moreover, keeping an aero-derivative gas turbine up and running is a real challenge for the service team. At Linquip you have access to diverse aero-derivative gas turbines across all verified gas turbine manufacturers and service providers which helps you to find the right choice. You can also contact our gas turbine suppliers directly to find the latest information about their new products and pricing.

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteAeroderivative Gas Turbine Subcategories

Top Companies in Aeroderivative Gas Turbine

+19 Companies in Aeroderivative Gas Turbine

Top Devices in Aeroderivative Gas Turbine

Fern Engineering, Inc.

Related RFQs

Aeroderivative Gas Turbine category

LNQ-23091023

Aeroderivative Gas Turbine

LNQ-23071162

Gas Turbine

LNQ-23051268

Gas Turbine

LNQ-23041063

Gas Turbine

LNQ-23031066

Aeroderivative Gas Turbine

LNQ-23011085

Aeroderivate Gas Turbine

LNQ-22121284

Commercial Aircraft Engine

LNQ-22111596

Top Aeroderivative Gas Turbine Experts

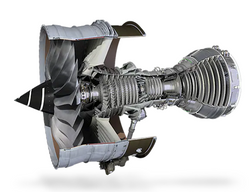

What are Aeroderivative Gas Turbines?

The aeroderivative gas turbine is a type of gas turbine with a lighter weight. Although it is classified as a gas turbine, the source of fuel for an aeroderivative turbine is not gas. In fact, they are designed to mix fuel and air and then ignite to produce the desired yield.

The gas turbines are comprised of a compression mechanism to help the taking in and the process of compression of air (the “gas†in this case) and then adding heat using a burner. The flow of hot air is used as the power supply for the turbine. Today, these are usually designed to use the combustion process, which is contrary to the intermittent nature of automotive combustion engines. Gas turbines have a long history of successful commercial applications since the late 1930s.

In general, aeroderivative gas turbines are based on existing aircraft gas turbine engines. They are lighter and smaller than industrial gas turbines. Aeroderivative gas turbines are utilized in electrical power generation due to their ability to be shut down and control load changes faster than industrial machines. Another application is in the marine industry to decrease weight.

From an engineering point of view, designing a gas turbine is less complicated than a more conventional piston engine. These units basically have a moving part. However, the complexity lies in the high degree of precision required in the construction and the materials used in their manufacture. Also, some modern designs use multiple shafts as well as hundreds of blades.

Aeroderivative Gas Turbines Applications

An area of extensive use of aeroderivative gas turbine technology is in aviation, where the power provided by the turbine is applied to power a compressor. The hot air coming out of the turbine is used for thrust by leading the air into the atmosphere through the exhaust nozzle.

Gas turbines that are not used in aircraft or other aviation-related machines use some of their power to supply the compression device. The remaining power is used to run an energy conversion device, like a generator or perhaps a propeller on a vessel. The turbine used to generate electrical power can be small enough to be installed on trucks for mobile implementations or large projects that take months to build.

The weight of Aeroderivative gas turbines is usually significantly less than those designed for land use. Heavier industrial models designed for land use are known as “frame†machines. Today, the aeroderivative models are more common in electrical power applications, albeit more for peak and intermittent goals rather than base power generation.

Aeroderivative Gas Turbines Strengths

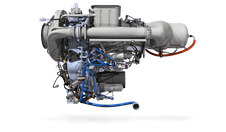

Aeroderivative gas turbines are popular for energy generation options because of their reliability, efficiency, and flexibility. Advanced aircraft engine technologies and materials have made them significantly lighter, respond faster, and have a smaller footprint than their heavy industrial gas turbine counterparts.

With an efficiency of up to 45% compared to up to 35% for heavier gas turbines, these turbines are often considered an appropriate choice in small-scale energy generation (up to 100 MW). The turbines are also popular for their fuel flexibility; they make it possible to combine natural gas and liquid fuel.

According to a 2016 study, the global market for aeroderivative gas turbines is expected to grow by nearly 5% annually between 2016 and 2020. Asia, in particular, extends many of these machines on power trains for Liquefied Natural Gas (LNG) power plants. In the United States, aeroderivatives are mainly used in various operations or to compensate for network fluctuations caused by renewables or severe weather conditions. Almost all the market for aeroderivatives comes from GE, Siemens, and Pratt & Whitney Power Systems (PWPS).

Aeroderivative Gas Turbines vs. Industrial Gas Turbines

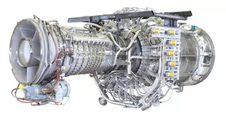

Optimum selection of gas turbines can be made after a complete comparison of turbines. The differences between aeroderivative and industrial gas turbines include weight, size, design, efficiency, bearing type, and lubrication system.

Aeroderivative gas turbine, as its name implies, is compatible with gas turbines used in aircraft (jet engines). However, the industrial gas turbine is manufactured assuming they would operate on land.

Heavy frame industrial gas turbines are usually slower than aeroderivative gas turbines, narrower in the speed range, heavier, larger, with higher airflow, slower at start-up, and require more time and spare components for maintenance. Heavy frame industrial gas turbines utilize hydrodynamic bearing.

Aeroderivative gas turbines are equipped with anti-friction bearing. To provide maintainable, flexible, lightweight, and small aeroderivative gas turbines, advanced aircraft engine technologies have been employed. Maintainability is the modular idea to remove components and replace them without eliminating the turbine from its support mounts. In contrast, industrial gas turbines need more effort to remove, replace, inspect, or repair the parts (particularly combustor components).

Traditionally, the priority has been to place the aeroderivative units in remote applications (including offshore) and place heavy frame industrial units in base-load applications that are easily accessible.

Industrial gas turbines consume more fuel and air than aeroderivative gas turbines. They are exposed to more contaminants in the air, causing corrosion.

Aeroderivative gas turbines are designed without secondary regeneration and are the only engines that extract mechanical work from fuel and do not use exhaust. So aeroderivative gas turbines are useful for simple cycle gas power plants that do not require the combined cycle or steam generation. Industrial gas turbines are designed so that the exhaust is to raise steam. The hotter the steam, the more usable it is in industrial utilization. Thus they are designed to generate hotter exhaust and are less efficient at converting heat into mechanical work.

Industrial turbines are used in factories and operate at a constant speed for long periods, so they are efficient only in a narrow power range. But aeroderivative gas turbines have more flexibility and efficiency over a wider range of power. Today aeroderivative gas turbines are 10-15% more efficient than heavy frame industrial type gas turbines. Some experts predict that in the future, aeroderivative gas turbines will replace heavy industrial gas turbines.