Marine Gas Turbine

Need industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteNeed industrial equipment, parts, or services? Submit an RFQ and get quick quotes.

Get a QuoteTop Companies in Marine Gas Turbine

+27 Companies in Marine Gas Turbine

Top Devices in Marine Gas Turbine

Related RFQs

Gas Turbine

LNQ-23051268

Gas Turbine

LNQ-23041063

Gas Turbine

LNQ-23031066

Marine Gas Turbine

LNQ-23011010

Gas Turbine

LNQ-22111170

Marine Gas Turbine

LNQ-22111161

Gas Turbine

LNQ-22101093

Gas Turbine

LNQ-22081112

Top Marine Gas Turbine Experts

What Are Marine Gas Turbines?

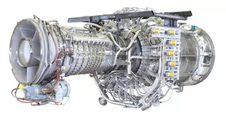

Marine Gas turbines are used in many naval vessels. They are considered due to their high power-to-weight ratio and their effect on ships’ acceleration and ability to start quickly. Gas turbines for propulsion have been used in many warships developed since the 1960s, such as a few passenger ships like the jetfoil. Gas turbines are generally employed in combination with other engine types. Recently, RMS Queen Mary 2 has installed gas turbines in addition to diesel engines.

The first marine gas turbine used to power a naval vessel was the Royal Navy's Motor Gun Boat MGB 2009 (formerly MGB 509) in 1947. In 1952 the Steam Gun Boat Grey Goose was transformed into the Rolls-Royce gas turbine and operated since 1953. In 1953 the first ships were created specifically for gas turbine propulsion.

The idea of applying a gas turbine to propel a ship dates back to 1937 when a free-piston gas engine of a form of the diesel engine was used experimentally with a gas turbine. In the late 1950s, gas turbine marine engines were widely used by the European navy in combination with conventional propulsion equipment. Gas turbines were employed for high-speed operation, and conventional plants were utilized for cruising.

In the shipping industry, the benefits of the gas turbine have constantly been overshadowed by its weaknesses. Basically, the high fuel and initial cost make it not an attractive option for ship owners. The most important consumers of marine gas turbines have traditionally been the world's navy and military. Recent signs of progress in gas turbine technology, along with lower oil prices and profitability in certain markets, have prompted ship owners to reconsider the values of the marine gas turbine.

The requirements for marine services include reliability, long lifetime, low maintenance cost, economy, occupied space, and weight.

Major Components of Marine Gas Turbines

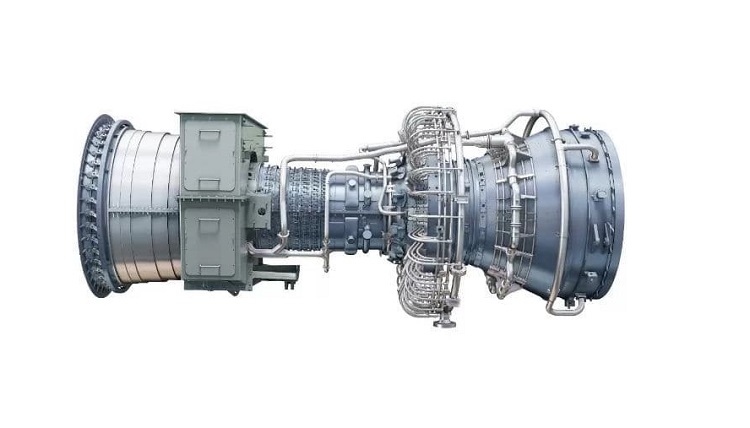

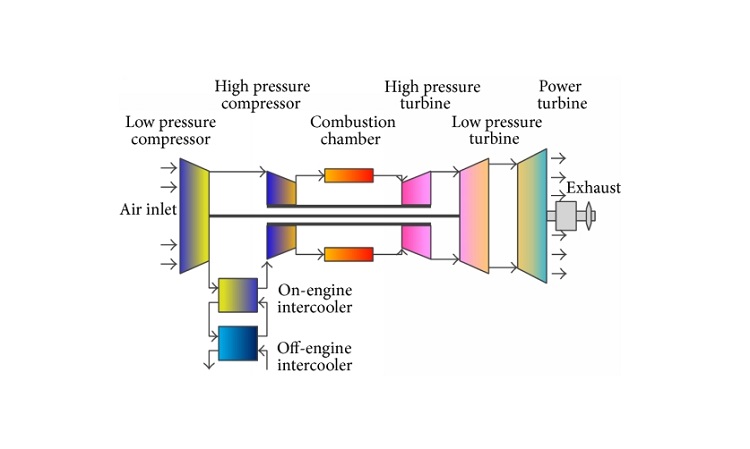

The marine gas turbines have four major parts, including a multi-stages pressure ratio compressor with variable stators and inlet guide vanes, a fully annular combustion chamber with mounted fuel nozzles, a multi-stages air-cooled high-pressure turbine to drive the compressor and the gearbox accessories, and a multi-stages aerodynamically coupled low-pressure power turbine driven by a high-energy exhaust gas flow through the gas generator.

Working Principle of Marine Gas Turbines

Due to the poor thermal efficiency at low power output (cruise), ships that use them usually have diesel engines for cruising and gas turbines for higher speeds. However, in the case of passenger ships, the principal reason for installing gas turbines is to reduce emissions in environmentally sensitive areas or ports.

Some warships and some modern cruise ships have also used steam turbines to enhance their gas turbines' efficiency in a combined cycle, where waste heat by a gas turbine exhaust is used to boil the water and produce steam to drive a steam turbine.

In such combined cycles, the thermal efficiency can be the same or somewhat higher than that of diesel engines; however, the amount of fuel needed for these gas turbines is much more expensive than that required for diesel engines. Therefore, the running costs are still higher.

In the following figure, a marine gas turbine structure is shown.

Marine gas turbines consist of the gas generator, the power turbine, fuel and lubrication oil pumps, speed governing and fuel control systems, inlet and exhaust parts, lubricant and scavenge sections, as well as devices for starting and monitoring the operation of the engine.

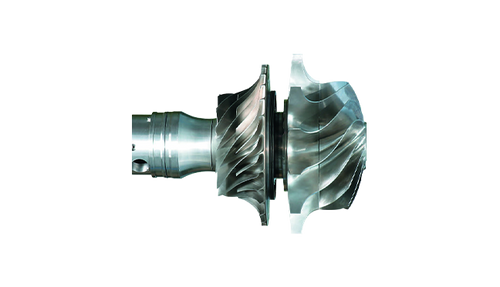

The compressor increases the air pressure, which is taken from the atmosphere. The device is a centrifugal or axial flow rotation one. This drive comes straight from the turbine, usually installed on the same shaft.

In the combustion chamber, the hot compressed air burns the injected fuel, which is typically a low viscosity petroleum oil. The ignition occurs to produce high-pressure gas. The gas temperature ranges from 850 to 1100 degrees Celsius. Then, it is expanded through a nozzle to change a portion of its thermal and pressure energy into kinetic energy. The high-velocity air flow strikes on the blades of the turbine.

Another complexity often found in marine gas turbines is the arrangement of two turbines in series. As described in the above lines, the compressor needs power which is obtained from the turbine itself. In a series setup, the first gas turbine, which is known as the compressor drive, high pressure, or gas generator, gives the drive for the compressor. The second turbine, which is known as the low pressure, free, or power turbine, is more suitable to run the propeller or generator.

With the help of this separation of tasks in the form of compressor and external load, a better torque characteristic can be achieved, such as the characteristic required for the ship propeller. The following figure depicts this.

Challenges of Employing a Marine Gas Turbine

The working environment of the marine gas turbines creates unique challenges. Salty air for combustion has never actually been a significant difficulty for diesel engines or steam power plants. But the large amount of air required by the gas turbine provides a large amount of moisture to enter the engine. So, the engine must be adjusted to prevent corrosion and the blocking by salt sediments for the marine gas turbine passages.

Another challenge to be considered with the gas turbine is the turbine exposure to a shock; propeller vibrations, pitching rolling, and such. Precise care must be taken to design, maintenance of support, and dampening structures.